A kind of modified liquor lees-based activated carbon and preparation method thereof

A technology of white distiller's grains and activated carbon, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as shortage, and achieve the effect of easy operation, simple method and suitable for industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]A method of preparing a variable liquor basin activated carbon, including the following steps:

[0030](1) Use the pulverizer to block the dry white wine to 80 mesh, then we will weigh 10g white wine in N2High temperature carbonization of 800 ° C under atmosphere 1 h;

[0031](2) 2 g of potassium hydroxide is added to the hydrothermal reactor, and 15 ml of deionized water is added, and the ultrasonic dissolution is formed to form a homogeneous solution, then add 2g of white wine after carbonization, mix well, at 180 ° C After 20 h; after cooling the heat reactor is cooled to room temperature, filtrate and washed with deionized water, then dried in an oven at 100 ° C, preparing activated activated carbon after activation;

[0032](3) 1 g of activated activated carbon is placed in a temperature of 70 ° C, and the mass fraction is 0.1%.

[0033](4) After the impregnation is completed, the filtch is filtered and dried at 100 ° C, then at 850 ° C, N2Calcination of 1 h in the atmosphere.

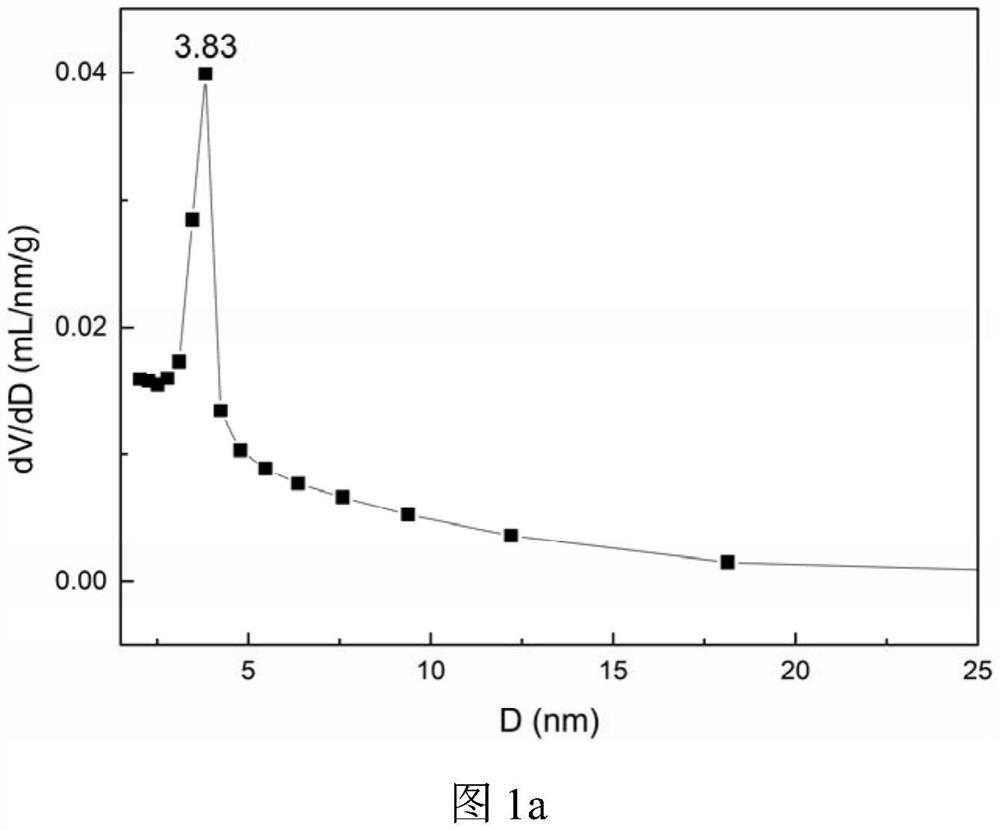

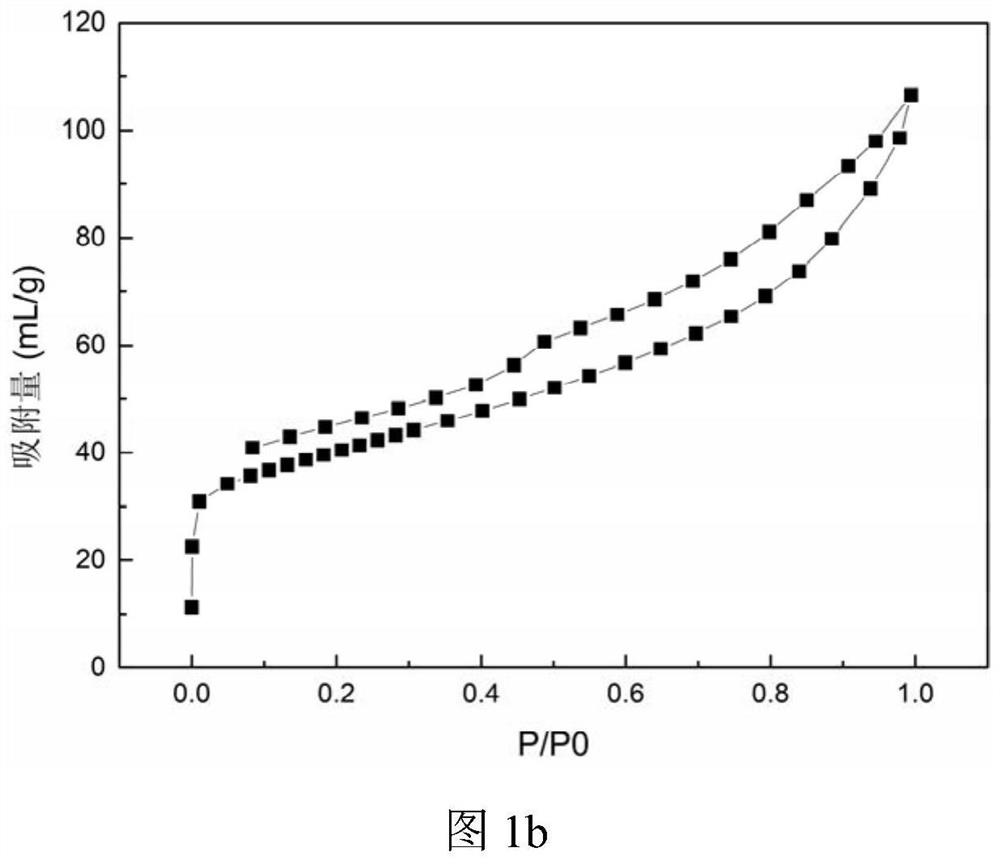

[0034]T...

Embodiment 2

[0036]A method of preparing a variable liquor basin activated carbon, including the following steps:

[0037](1) Use a crusher to smash the dry white wine to 100 mesh, then we will weigh 10g white wine in N2High temperature carbonization of 700 ° C under atmosphere 1 h;

[0038](2) 2 g of potassium hydroxide is added to the hydrothermal reactor, and 15 ml of deionized water is added, and the ultrasonic dissolution is formed to form a homogeneous solution, then add 2g of white wine after carbonization, mix well, at 180 ° C The lower water is hot and reflecting 16 h; after cooling to room temperature, filtrate and washed with deionized water, then dried in an oven at a 100 ° C oven to prepare the activated activated carbon;

[0039](3) 1 g activated activated carbon is placed in a melamine solution having a temperature of 80 ° C and a mass fraction of 0.3%;

[0040](4) After the impregnation is completed, the filtch is filtered and dried at 100 ° C, then at 850 ° C, N2Calcination of 1 h in the at...

Embodiment 3

[0043]A method of preparing a variable liquor basin activated carbon, including the following steps:

[0044](1) Use the pulverizer to block the dry white wine to 100 ~ 150 mesh, then we will weigh 10g white wine in N2High temperature carbonization of 800 ° C under atmosphere 2h;

[0045](2) 2 g of potassium carbonate is added to the hydrothermal reaction kettle, and then 15 ml of deionized water, ultrasonic dissolution form a homogeneous solution, then add 2g carbonized white wine powder, mix well, under the conditions of 180 ° C Thermally reactive 16h; after cooling to room temperature, filtered and washed with deionized water, then dried in an oven at 100 ° C, and prepared activated activated carbon;

[0046](3) 1 g activated activated carbon is placed in a melamine solution of 80 ° C and a mass fraction of 0.4%;

[0047](4) After the impregnation is completed, filtch and dried at 100 ° C, then at 950 ° C, N2Calcination of 1 h in the atmosphere.

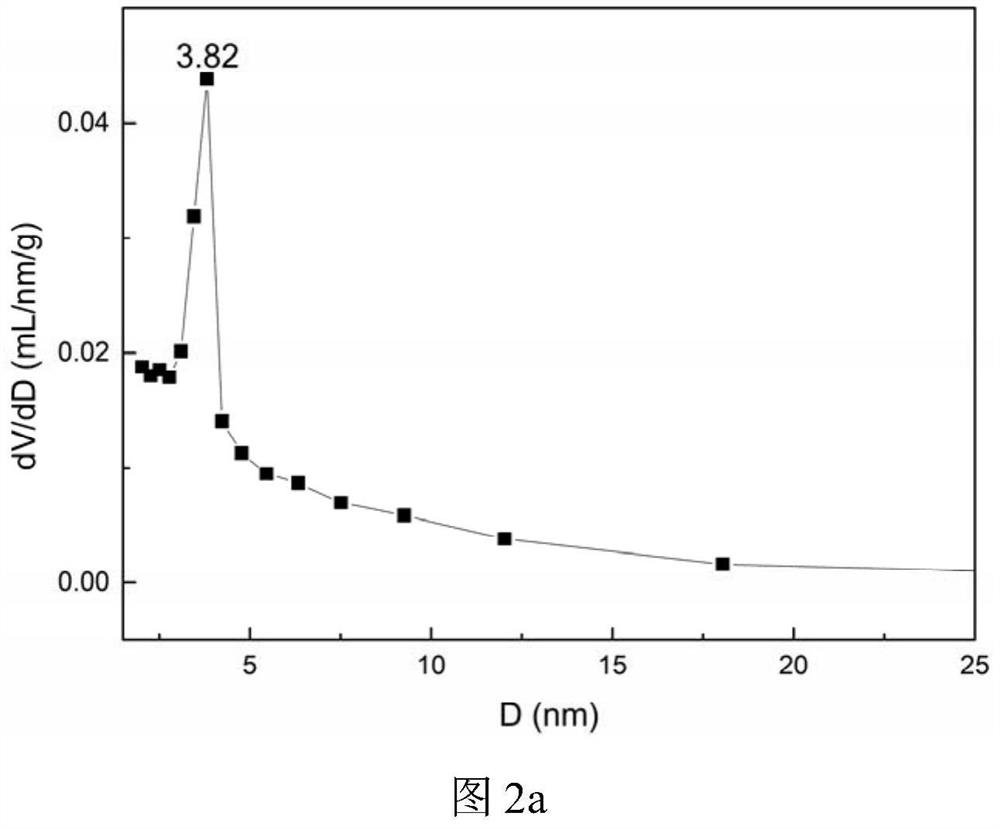

[0048]The resulting activated carbon is charact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com