Kitchen waste resource utilization method

A kitchen waste and recycling technology, applied in the field of environmental biology, can solve the problems of viruses and bacteria endangering human health, threats to human health, and prone to corruption, so as to strengthen the effect of natural reoxygenation pretreatment, and overcome costs and operating costs. , to achieve the effect of cleaning transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

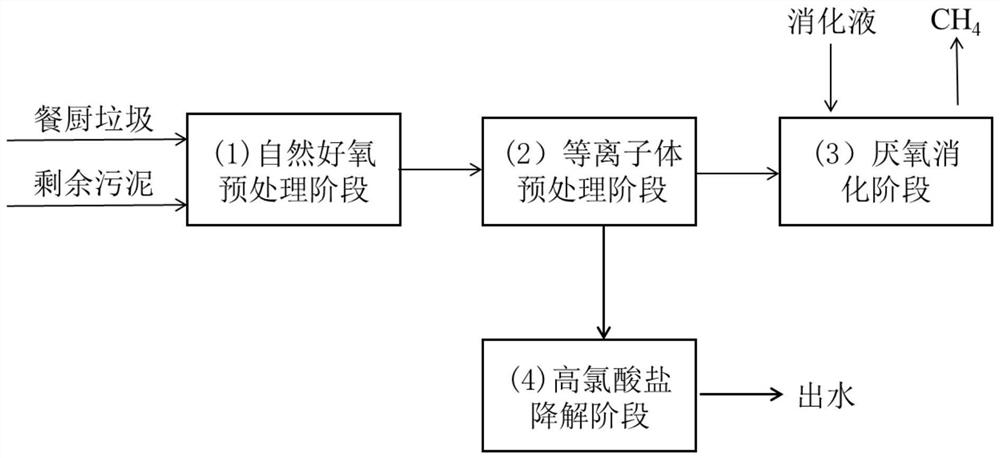

[0035] A method for recycling food waste, comprising the following steps:

[0036] (1) After blending the food waste and sludge, carry out aerobic fermentation and decomposing pretreatment for 6 days under natural conditions to obtain the pretreatment substrate;

[0037] Among them, the proportion of volatile organic compounds: food waste with a mass fraction of 25%, sludge with a mass fraction of 75%;

[0038] (2) Low-temperature plasma is used to carry out secondary treatment on the pretreated substrate in step (1). The low-temperature plasma treatment method is: inject the pretreated substrate into the quartz tube through a syringe pump at a flow rate of 20 mL / h, and then inject the pretreated substrate into the quartz tube at a flow rate of 100 mL. / min nitrogen atmosphere, under the conditions of temperature 300 ℃, pulse power supply 20kW, the product was obtained;

[0039] (3) subjecting the product of step (2) to solid-liquid separation to obtain supernatant and bottom...

Embodiment 2

[0045] A method for recycling food waste, comprising the following steps:

[0046](1) After blending the food waste and sludge, carry out aerobic fermentation and decomposing pretreatment for 6 days under natural conditions to obtain the pretreatment substrate;

[0047] Among them, the proportion of volatile organic compounds: food waste with a mass fraction of 50%, and sludge with a mass fraction of 50%;

[0048] (2) Low-temperature plasma is used to carry out secondary treatment on the pretreated substrate in step (1). The low-temperature plasma treatment method is: inject the pretreated substrate into the quartz tube through a syringe pump at a flow rate of 20 mL / h, and then inject the pretreated substrate into the quartz tube at a flow rate of 100 mL. / min nitrogen atmosphere, under the conditions of temperature 300 ℃, pulse power supply 20kW, the product was obtained;

[0049] (3) subjecting the product of step (2) to solid-liquid separation to obtain supernatant and bot...

Embodiment 3

[0055] A method for recycling food waste, comprising the following steps:

[0056] (1) After blending the food waste and sludge, carry out aerobic fermentation and decomposing pretreatment for 6 days under natural conditions to obtain the pretreatment substrate;

[0057] Among them, the proportion of volatile organic compounds: food waste with a mass fraction of 100%, sludge with a mass fraction of 0%;

[0058] (2) Low-temperature plasma is used to carry out secondary treatment on the pretreated matrix of step (1). The low-temperature plasma treatment method is: the pretreated matrix is injected into the quartz tube through a syringe pump at a flow rate of 15mL / h, and the flow rate is 110mL / min in a nitrogen atmosphere, at a temperature of 250°C and a pulse power supply of 25kW, the product was obtained;

[0059] (3) subjecting the product of step (2) to solid-liquid separation to obtain supernatant and bottom slag;

[0060] (4) get the supernatant of step (3) as electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com