Method for promoting hydrolysis and fermentation of excess sludge and simultaneously utilizing fermentation product in situ

A technology for excess sludge and fermentation products, applied in water/sludge/sewage treatment, water pollutants, sludge treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

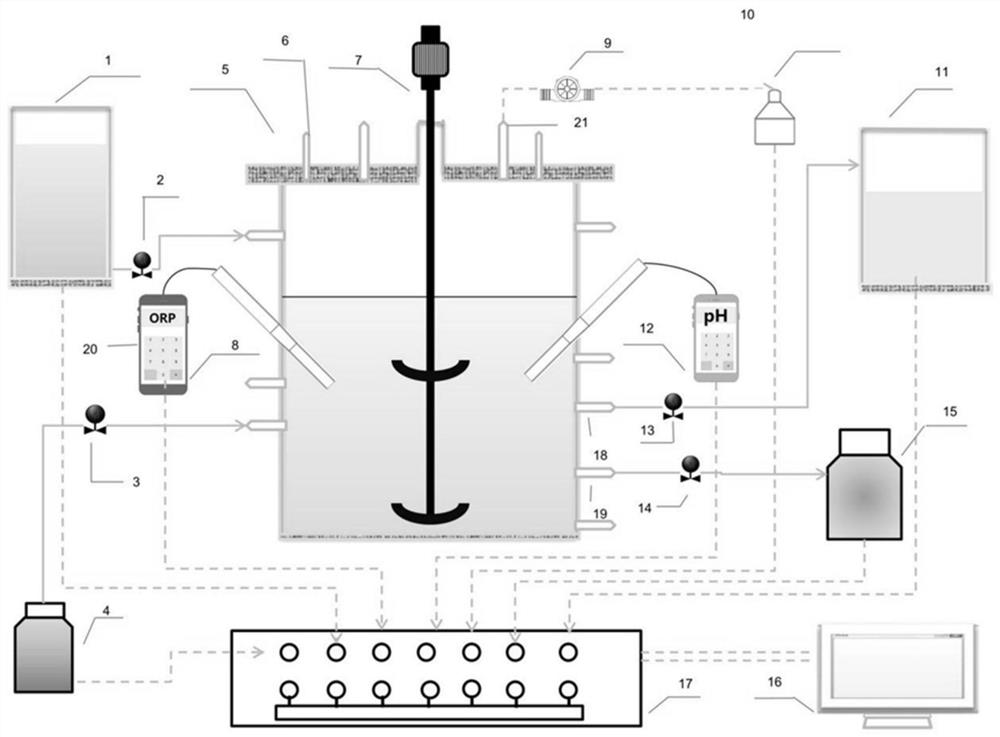

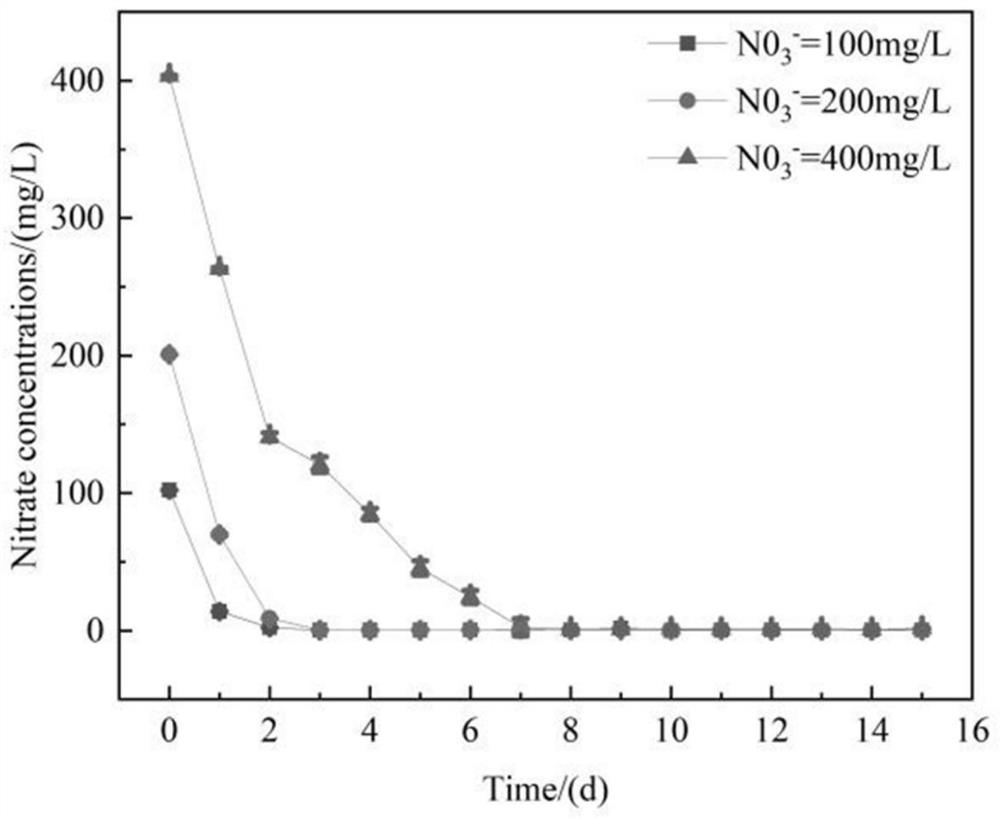

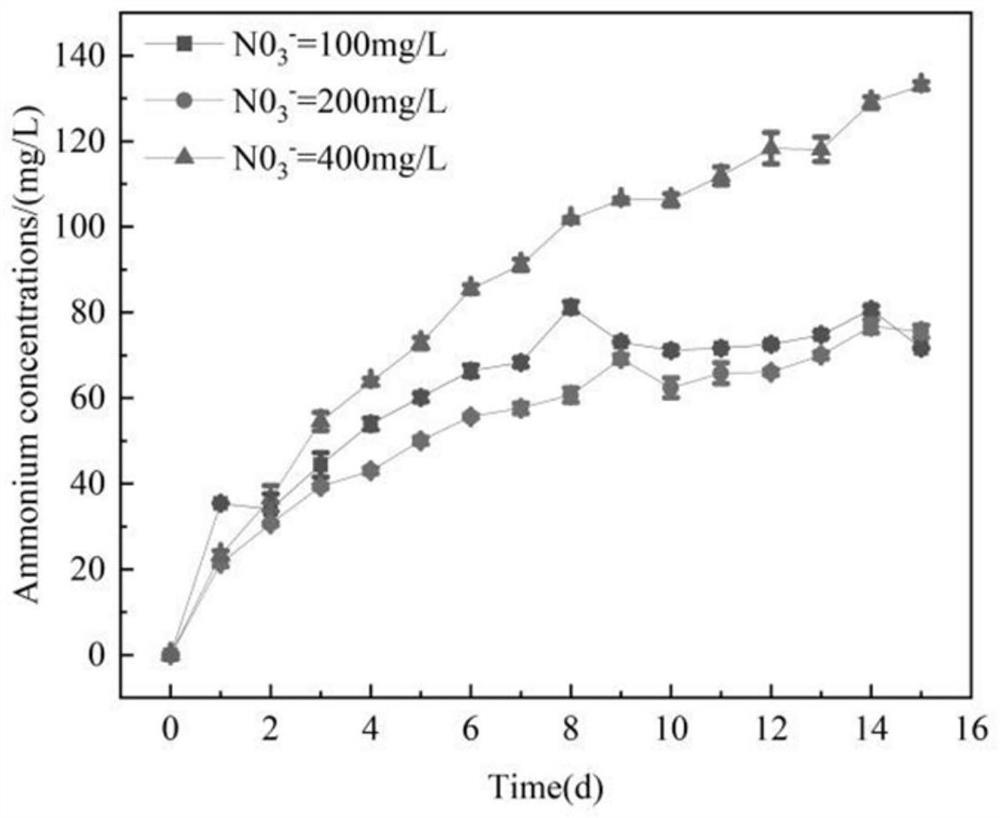

[0030] ⅠAdding mud: the fermentation substrate in the mud storage tank (4) is taken from the remaining sludge in the secondary sedimentation tank of the urban sewage treatment plant, and after standing at 4°C for 48 hours, the supernatant is removed to obtain a sludge sample; The mud pump (3) makes the sludge total suspended solid concentration in the sludge anaerobic fermentation system (5) be 9.2g / L, and the volatile suspended solid concentration be 5.8g / L.

[0031] II Influent water: The influent water tank (1) is artificially prepared nitrate-nitrogen wastewater. By controlling the raw water inlet pump (2), the concentration of nitrate-nitrogen wastewater in the sludge anaerobic fermentation system (5) is 100mg / L.

[0032] Ⅲ Air intake: fill the sludge anaerobic fermentation system (5) with N for 5min through the intake valve (21) 2 , to remove oxygen from the reactor.

[0033] Ⅳ Anoxic stirring: keep the airtight state of the sludge anaerobic fermentation system (5), adj...

Embodiment example 2

[0040] ⅠAdding mud: the fermentation substrate in the mud storage tank (4) is taken from the remaining sludge in the secondary sedimentation tank of the urban sewage treatment plant, and after standing at 4°C for 48 hours, the supernatant is removed to obtain a sludge sample; The mud pump (3) makes the sludge total suspended solid concentration in the sludge anaerobic fermentation system (5) be 9.2g / L, and the volatile suspended solid concentration be 5.8g / L.

[0041] II Influent water: The influent water tank (1) is artificially prepared nitrate-nitrogen wastewater. By controlling the raw water inlet pump (2), the concentration of nitrate-nitrogen wastewater in the sludge anaerobic fermentation system (5) is 200mg / L.

[0042] Ⅲ Air intake: fill the sludge anaerobic fermentation system (5) with N for 5min through the intake valve (21) 2 , to remove oxygen from the reactor.

[0043] Ⅳ Anoxic stirring: keep the airtight state of the sludge anaerobic fermentation system (5), adj...

Embodiment example 3

[0050] ⅠAdding mud: the fermentation substrate in the mud storage tank (4) is taken from the remaining sludge in the secondary sedimentation tank of the urban sewage treatment plant, and after standing at 4°C for 48 hours, the supernatant is removed to obtain a sludge sample; The mud pump (3) makes the sludge total suspended solid concentration in the sludge anaerobic fermentation system (5) be 9.2g / L, and the volatile suspended solid concentration be 5.8g / L.

[0051] II Influent water: the nitrate-nitrogen wastewater is artificially prepared in the water inlet tank (1). By controlling the raw water inlet pump (2), the concentration of nitrate-nitrogen wastewater in the sludge anaerobic fermentation system (5) is 400mg / L.

[0052] Ⅲ Air intake: fill the sludge anaerobic fermentation system (5) with N for 5min through the intake valve (21) 2 , to remove oxygen from the reactor.

[0053] Ⅳ Anoxic stirring: keep the airtight state of the sludge anaerobic fermentation system (5),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com