High-efficiency biological fluidized bed reactor

A technology of biological fluidized bed and reactor, which is applied in the fields of chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc. It can solve daily life health hazards, low treatment efficiency, large volume of reaction pool, etc. problems, to achieve the effect of reducing sludge resistance, enhancing disturbance, and increasing aeration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

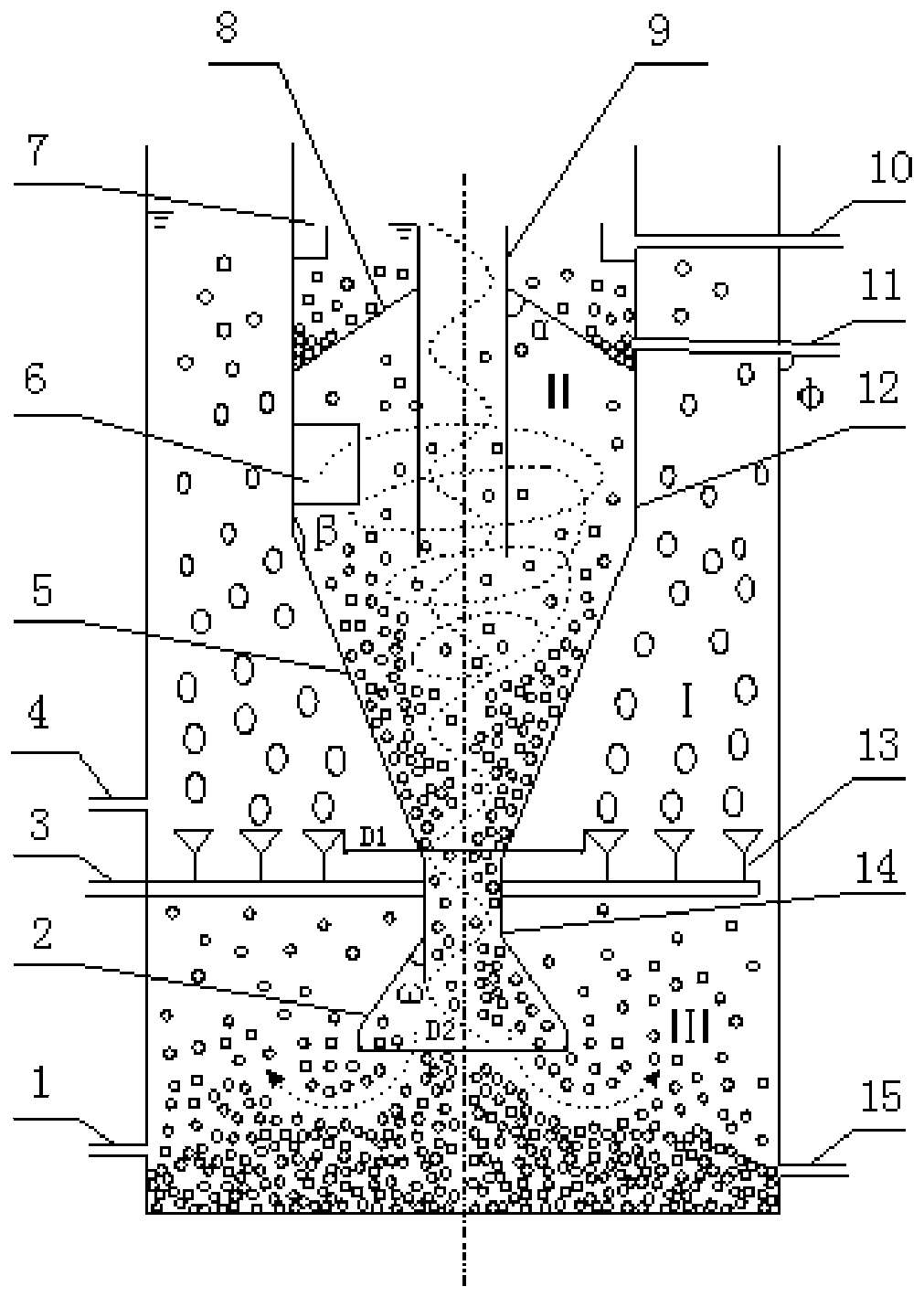

[0021] Such as figure 1 As shown, a high-efficiency biological fluidized bed reactor provided by the present invention includes a reactor main body, and an activated sludge cyclone separator is arranged in the reactor main body, and it is characterized in that the activated sludge cyclone separator The interior of the reactor body is the first anoxic zone II, the bottom of the reactor main body is the second anoxic zone III, and the upper part is the aerobic zone I. The first water inlet 1 is provided on one side of the bottom of the second anoxic zone III, and the other There is a first mud discharge port 15 on the side, and an aeration main pipe 3 is provided on one side of the bottom of the aerobic zone I, and a plurality of disc aeration pans 13 are arranged on the aeration main pipe 3, and a second aeration pipe 3 is arranged above the aeration main pipe 3 Two water inlets 4; disc aeration discs 13 are evenly distributed on the outer edge of the lower column 14; the diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com