Converter fettling material and preparation method thereof

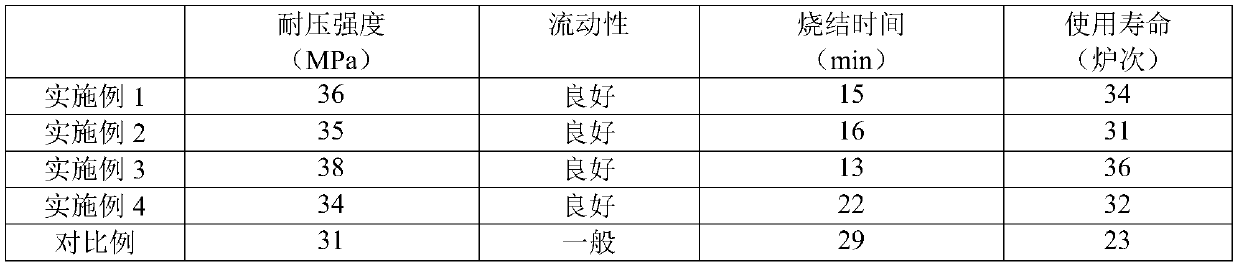

A technology of repairing materials and converters, which is applied in the field of converter repairing materials and its preparation, which can solve the problems of low strength, short service life and long sintering time of repairing materials, and achieve high economic benefits, long service life and shortened sintering time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A converter repair charge, prepared from the following raw materials in parts by weight: 8 parts of fused magnesia with a particle size of <0.088 mm, 6 parts of fused magnesia with a particle size of 0.088-1 mm, 15 parts of fused magnesia with a particle size of 1-3 mm, 38 parts of 3-5mm fused magnesia, 13 parts of 5-12mm fused magnesia, 12 parts of high-temperature asphalt, 4 parts of medium-temperature asphalt, 3 parts of tar, and 1 part of metal silicon powder.

[0020] Preparation:

[0021] The raw materials are weighed in proportion and stirred for 20 minutes to obtain a mixture; the mixture is pressed into a ball with a diameter of 30 mm by a ball press to obtain the converter repair charge.

Embodiment 2

[0023] A converter repair charge, prepared from the following raw materials in parts by weight: 11 parts of fused magnesia with a particle size of <0.088 mm, 7 parts of fused magnesia with a particle size of 0.088-1 mm, 18 parts of fused magnesia with a particle size of 1-3 mm, 35 parts of fused magnesia of 3-5mm, 15 parts of fused magnesia of 5-12mm, 8 parts of high-temperature asphalt, 2 parts of medium-temperature asphalt, 1 part of paraffin oil, and 3 parts of metal chromium powder.

[0024] The raw materials were weighed according to the proportion and stirred for 25 minutes to obtain a mixture; the mixture was pressed into a ball with a diameter of 40 mm by a ball press to obtain the converter repair charge.

Embodiment 3

[0026] A converter repair charge, prepared from the following raw materials in parts by weight: 8 parts of fused magnesia with a particle size of <0.088mm, 8 parts of fused magnesia with a particle size of 0.088-1mm, 16 parts of fused magnesia with a particle size of 1-3mm, 36 parts of 3-5mm fused magnesia, 14 parts of 5-12mm fused magnesia, 10 parts of high-temperature asphalt, 4 parts of medium-temperature asphalt, 2 parts of paraffin oil, and 2 parts of metal silicon powder.

[0027] The raw materials are weighed in proportion and stirred for 20 minutes to obtain a mixture; the mixture is pressed into a ball with a diameter of 40 mm by a ball press to obtain the converter repair charge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com