High-iron low-grade nickel sulfide ore selective biological leaching process

A technology of biological leaching and nickel sulfide ore, applied in the direction of improving process efficiency, etc., can solve the problem of high recovery cost of valuable metals, achieve low cost, reduce processing cost, and save investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

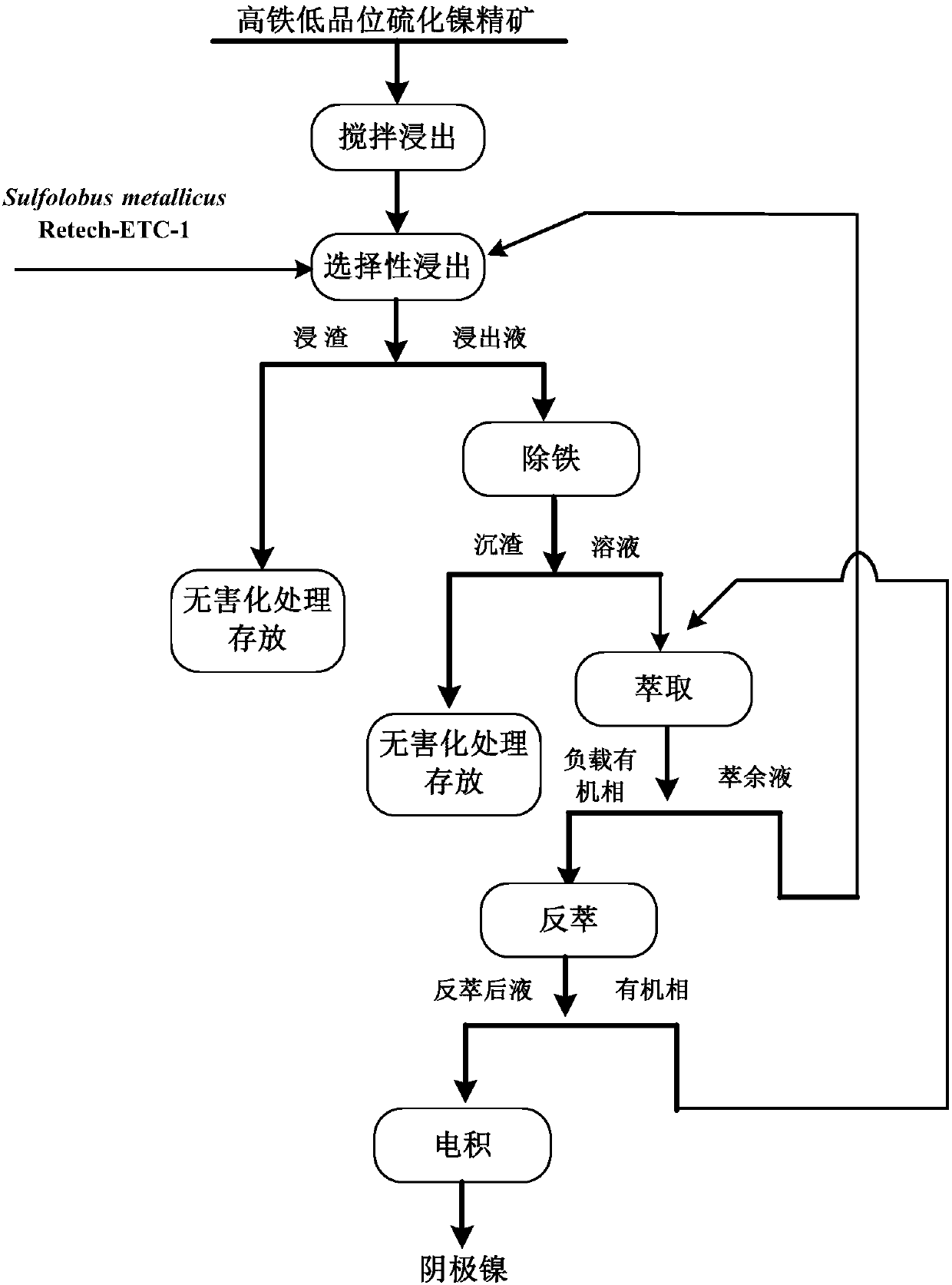

Method used

Image

Examples

Embodiment 1

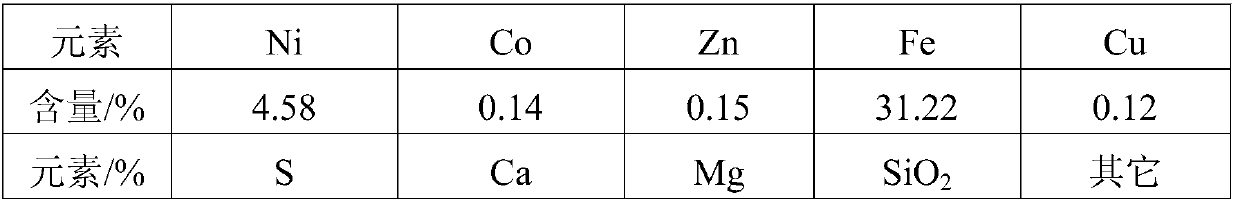

[0051] A domestic company in Jilin flotation nickel concentrate, the iron content is relatively high, and most of them exist in the form of pyrrhotite and pyrite, the main element analysis is shown in Table 1:

[0052] Table 1 Analysis of main elements of ore

[0053]

[0054]

[0055] The ore contains a large amount of quartz and silicate, nickel exists in the form of nickel sulfide and pentlandite, and iron mainly exists in the form of pyrite and pyrrhotite.

[0056] condition:

[0057] The pulp concentration is 18%, the pH value is 1.2, the inoculation amount of the exclusive sulfur oxidizing bacteria Sulfolobus metallicus Retech-ETC-1 is 10%, the shaking table speed is 200r / min, the temperature is 45°C, and the leaching cycle is 12d.

[0058] The results are shown in Table 2:

[0059] Table 2 Leaching results

[0060]

[0061] According to the above conditions, the leaching rate of nickel reached 86.78%, the leaching rate of sulfur was 46.24%, and the le...

Embodiment 2

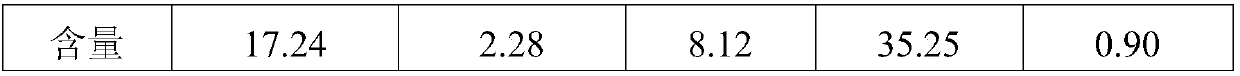

[0063] A domestic company in Gansu flotation nickel concentrate, the iron content is relatively high, and most of them exist in the form of pyrrhotite and pyrite, the main element analysis is shown in Table 3:

[0064] Table 3 Analysis of main elements of ore

[0065] element

Ni

co

Zn

Fe

Cu

content / %

4.72

0.18

0.13

32.43

0.18

element / %

S

Ca

Mg

SiO 2

other

content

16.85

2.34

7.89

34.15

1.13

[0066] The ore contains a large amount of quartz and silicate, nickel exists in the form of nickel sulfide and pentlandite, and iron mainly exists in the form of pyrite and pyrrhotite.

[0067] condition:

[0068] The pulp concentration is 18%, the pH value is 1.2, the inoculation amount of bacteria Sulfolobus metallicus Retech-ETC-1 is 10%, the shaking table speed is 200r / min, the temperature is 40-45°C, and the leaching cycle is 12d.

[0069] The results are shown in Table 4:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com