A method for regulating vacancy defects in materials

A technology of vacancy defects and functional materials, applied in the field of microelectronic materials, can solve problems such as performance failure and formation of voids, and achieve the effect of improving speed, improving speed of erasing and writing, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

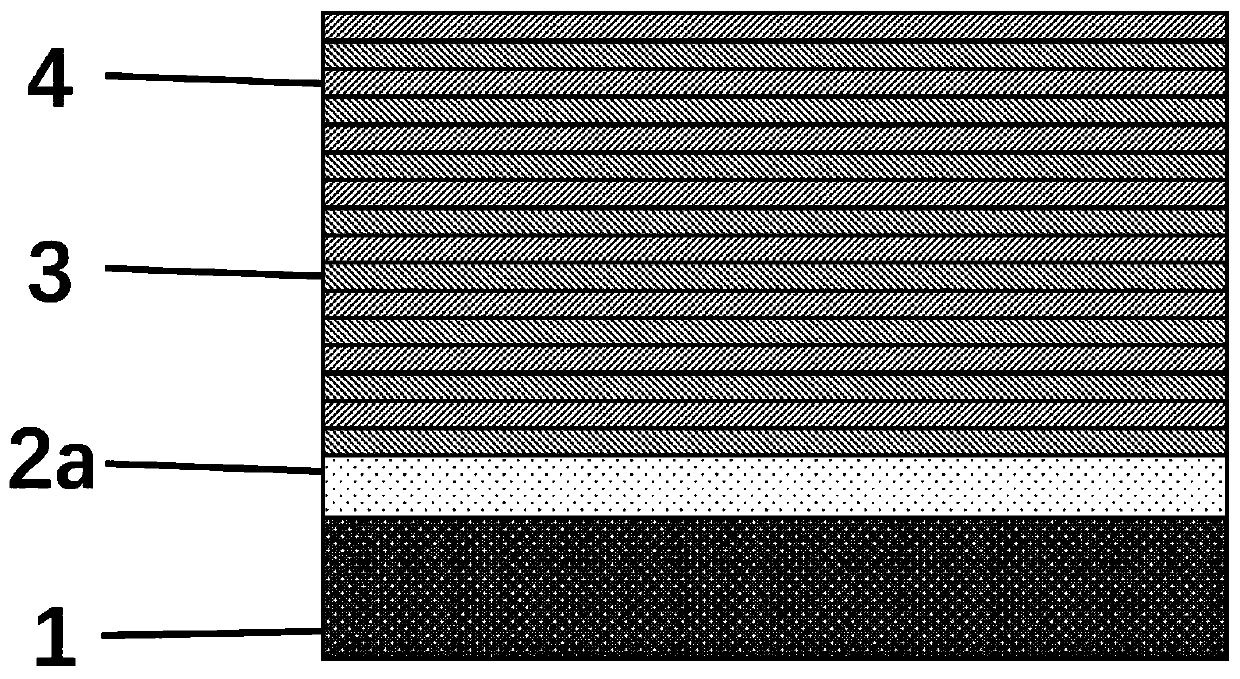

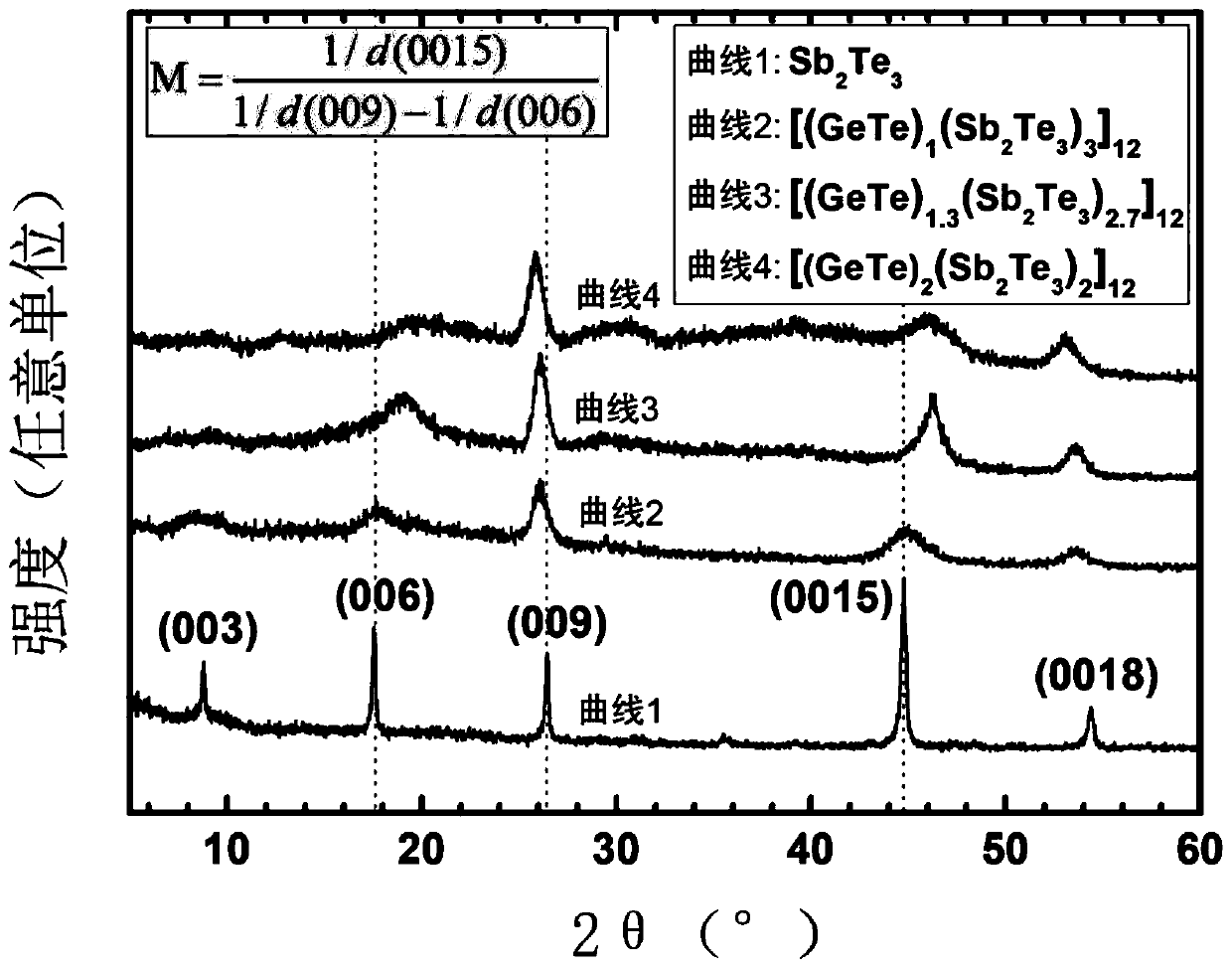

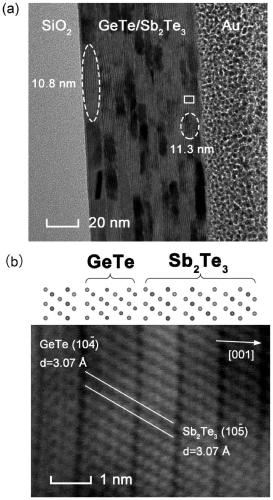

[0049] The structure of the multilayer phase change stress film prepared in the present embodiment is [A m B n ] l , where m and n represent the thicknesses of A and B respectively, the default unit is nm (nanometer), and l is the number of cycles of alternate growth of the multilayer film. 1 / 102 Te 3 , m / n are 4 / 0, 2 / 2, 1.3 / 2.7, 1 / 3 respectively, and l is 12. GeTe is a microscopic non-layered material with no van der Waals gap. Sb 2 Te 3 It is a microscopic layered material containing van der Waals gap, and its crystallization temperature is lower than that of GeTe, and it will crystallize before GeTe in the phase transition process. Therefore, the crystallization characteristics of the multilayer film (such as SET speed, etc.) are mainly determined by the slower crystallization speed of GeTe. Sb 2 Te 3 Although the crystallization of the multilayer film does not play a decisive role in the crystallization process of the multilayer film, it can exert stress on GeTe t...

Embodiment 2

[0087] In this embodiment, the multi-layer stress thin film structure is prepared as a phase change unit, and the SET speed test is carried out. Multilayer film [A m B n ] l A is still GeTe, B is still Sb 2 Te 3 , GeTe and Sb 2 Te 3 The thickness ratio is still: 4 / 0, 2 / 2, 1.3 / 2.7, 1 / 3, and the number of cycles is still fixed at 12. The preparation process of the multilayer film structure phase change unit is as follows:

[0088] (1) if Figure 5 As shown in (a), on the substrate composed of layer 1 and layer 2a, the lower electrode 5a layer is first deposited by magnetron sputtering, and the 5a layer is made of inert electrode materials such as Pt, TiW, and Ta.

[0089] (2) Deposit insulating layer 2b on layer 5a by physical vapor deposition (PECVD), layer 2b is SiO 2 , SiC, Al 2 o 3 and other insulating materials.

[0090](3) A photoresist mask with circular holes with a diameter of 250 nm was formed on the insulating layer 2 b by using an electron beam exposure s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com