Light-emitting diode device and preparation method thereof

A technology of light-emitting diodes and composite light-emitting layers, applied in the field of quantum dots, can solve the problems affecting the carrier transport performance of QLED luminous efficiency, stability, etc., to improve luminous efficiency and device stability, easy to repeat, and promote excited states The effect of complex electroluminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] On the other hand, an embodiment of the present invention also provides a method for manufacturing a light emitting diode, which includes the following steps:

[0023] S01: Provide the anode;

[0024] S02: depositing the composite light-emitting layer on the anode;

[0025] S03: depositing the electron transport layer on the composite light-emitting layer;

[0026] S04: Depositing the cathode on the electron transport layer.

[0027] The preparation method of the light-emitting diode provided by the embodiment of the present invention is simple, easy to repeat, and easy to realize large-scale preparation, and the final light-emitting diode can not only promote the carrier transport performance, but also promote the perovskite quantum dot material and The synergistic effect of non-perovskite quantum dot materials produces excited state complex electroluminescence, which improves the luminous efficiency of the light-emitting diode and the stability of the device.

[0028] Further, ...

Embodiment 1

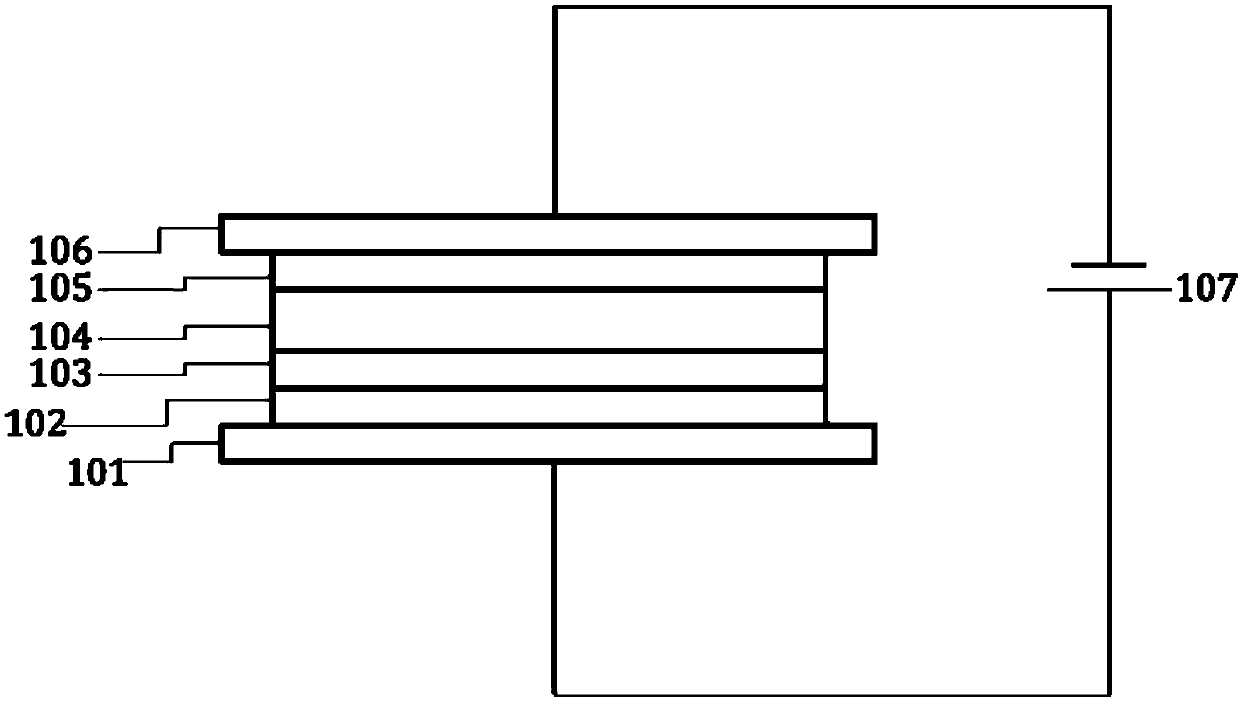

[0042] A QLED device whose structural components are described as follows from bottom to top: glass substrate / ITO / PEDOT:PSS / TFB / CdSe@ZnS / CH 3 NH 3 PbBr 3 / Surface modified ZnO & unmodified ZnO / Al, its preparation method is as follows:

[0043] a. Spin-coating a layer of PEDOT:PSS film on the ITO substrate as a hole injection layer;

[0044] b. Spin-coating a TFB layer on the PEDOT:PSS layer;

[0045] c. Spin-coating a CdSe@ZnS quantum dot layer on the TFB layer, and then spin-coating a layer of CH on the quantum dot layer 3 NH 3 PbBr 3 Organic-inorganic hybrid perovskite layer to obtain quantum dot composite light-emitting layer;

[0046] d. Dissolve nano-ZnO in ethanol to form a 30mg / mL solution, pour into the solution and nano-ZnO with a weight ratio of 1:30 ethanedithiol, keep it in a water bath at 40°C for 3 hours, stop stirring and cool. After the solution is completely cooled, it is spin-coated on the quantum dot composite light-emitting layer to obtain a surface-modified nano-...

Embodiment 2

[0049] A light-emitting diode device whose structural materials are described in order from bottom to top: glass substrate / ITO / PEDOT:PSS / TFB / CdSe@ZnS / CH 3 NH 3 PbBr 3 / Surface modified ZnO / Al, its preparation method is as follows:

[0050] a. Spin-coating a layer of PEDOT:PSS film on the ITO substrate as a hole injection layer;

[0051] b. Spin-coating a TFB layer on the PEDOT:PSS layer;

[0052] c. Spin-coating a CdSe@ZnS quantum dot layer on the TFB layer, and then spin-coating a layer of CH on the quantum dot layer 3 NH 3 PbBr 3 Organic-inorganic hybrid perovskite layer to obtain quantum dot composite light-emitting layer;

[0053] d. Dissolve nano-ZnO in ethanol to form a 30mg / mL solution, pour into the solution and nano-ZnO with a weight ratio of 1:30 ethanedithiol, keep it in a water bath at 40°C for 3 hours, stop stirring and cool. After the solution is completely cooled, it is spin-coated on the quantum dot composite light-emitting layer to obtain a surface-modified nano-ZnO l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com