White-light quantum dot light-emitting diode and preparation method thereof

A quantum dot luminescence and quantum dot technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problem that multi-layer quantum dot films cannot be stacked layer by layer, and achieve sufficient and good ligand replacement. Choice of flexible, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] On the one hand, an embodiment of the present invention provides a method for preparing a white light quantum dot light-emitting diode, comprising the following steps:

[0021] S01: Provide bottom electrode;

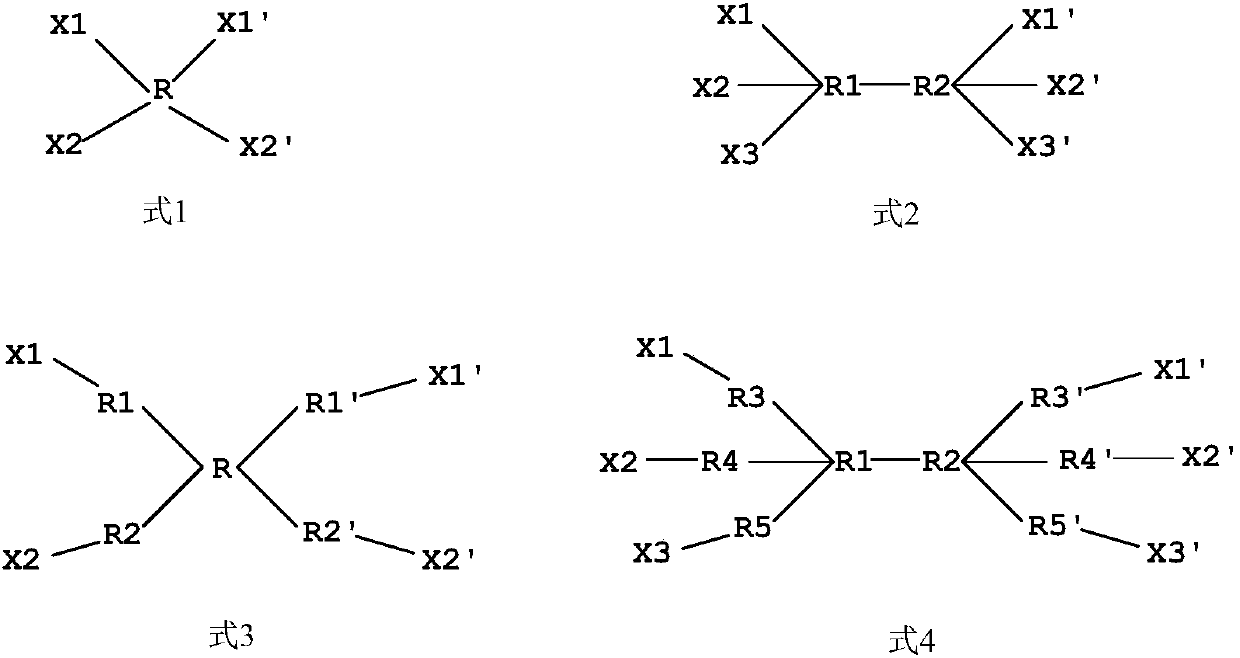

[0022] S02: prepare a quantum dot prefabricated film on the bottom electrode, and the surface of the quantum dots in the quantum dot prefabricated film is connected with an initial ligand; place the quantum dot prefabricated film in a sealable device, and pass gaseous replacement Ligand, performing gas phase ligand replacement to obtain a first layer of quantum dot film with the replacement ligand bound on the surface of the quantum dot, and the replacement ligand can connect at least two quantum dots;

[0023] S03: using the method for preparing the first layer of quantum dot films to prepare N-layer stacked quantum dot films to obtain a light-emitting stack; or

[0024] Using the method for preparing the first quantum dot film to obtain N-1 layered quantum dot ...

Embodiment 1

[0060] A preparation method of a quantum dot film, comprising the following steps:

[0061] Provide a prefabricated film of CdSe quantum dots, transfer the prefabricated film of quantum dots into a vacuum chamber, and pass 1,2-ethanedithiol gas, wherein the internal pressure of the vacuum chamber is 5Pa, 1,2-ethanedithiol The partial pressure of the gas was 1Pa, the temperature inside the chamber was 25°C, and the treatment time was 30min. After the treatment, the film was taken out to obtain a CdSe quantum dot film in which the ligand was replaced by 1,2-ethanedithiol.

Embodiment 2

[0063] A preparation method of a white light quantum dot light-emitting diode, comprising the following steps:

[0064] The PEDOT hole injection layer, the TFB hole transport layer, and the first layer of CdSe red quantum dot prefabricated films were printed in sequence on the ITO anode;

[0065] The first layer of CdSe red light quantum dot prefabricated film prepared above was transferred into a vacuum chamber, and 1,2-ethanedithiol gas was introduced, wherein the internal pressure of the chamber was 5Pa and the proportion of 1,2-ethanedithiol gas. The pressure is 1Pa, the temperature inside the chamber is 25°C, and the treatment time is 30min. After the treatment, it is taken out to obtain the first layer of CdSe red quantum dot film after ligand replacement;

[0066] A second layer of CdSe green quantum dot prefabricated film was printed on the first layer of CdSe red quantum dot film replaced by ligands, and then the second layer of CdSe green quantum dot film was transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com