Nb and Ta co-doped garnet-type LLZO solid electrolyte and preparation method thereof

A solid electrolyte and garnet-type technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve problems such as explosion, easy corrosion, and flammability of organic electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

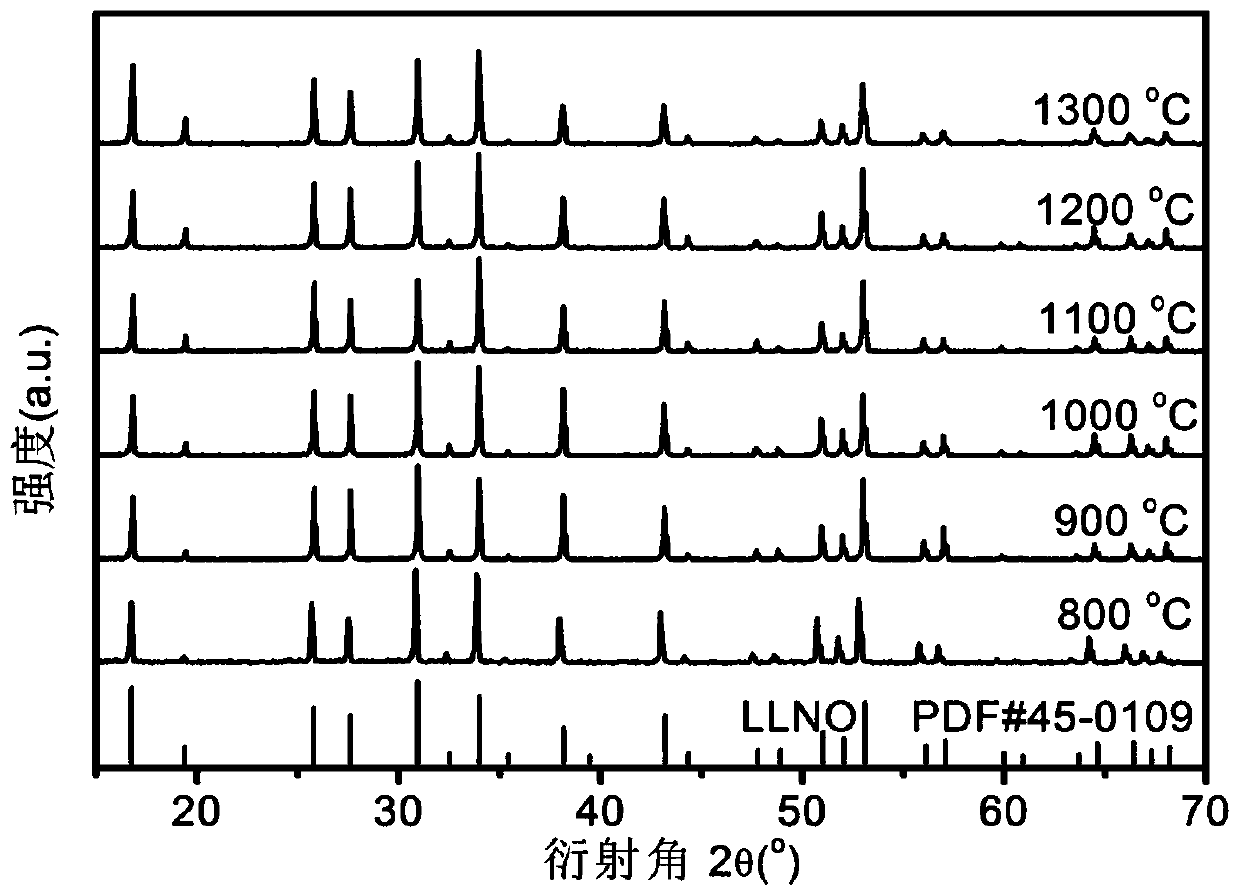

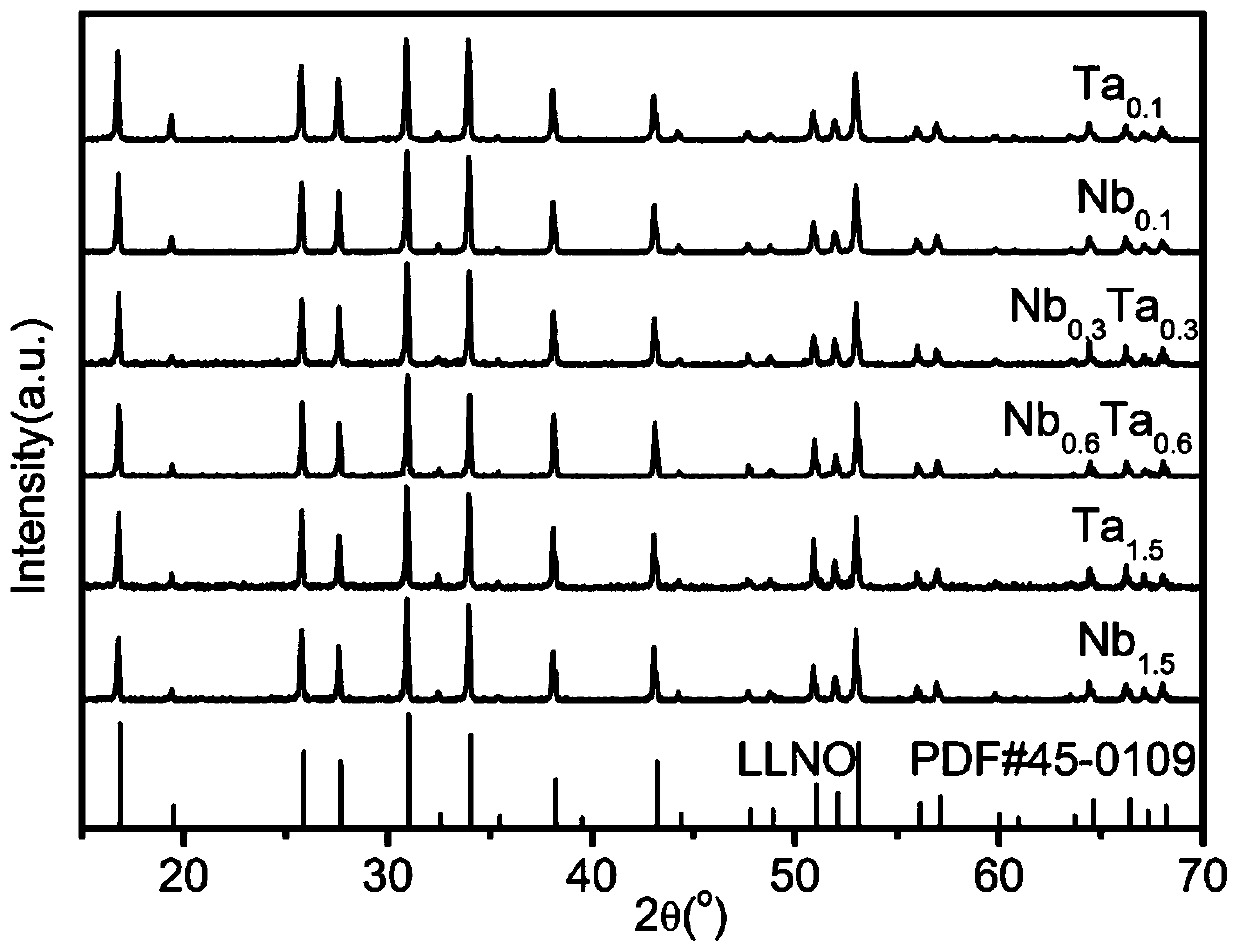

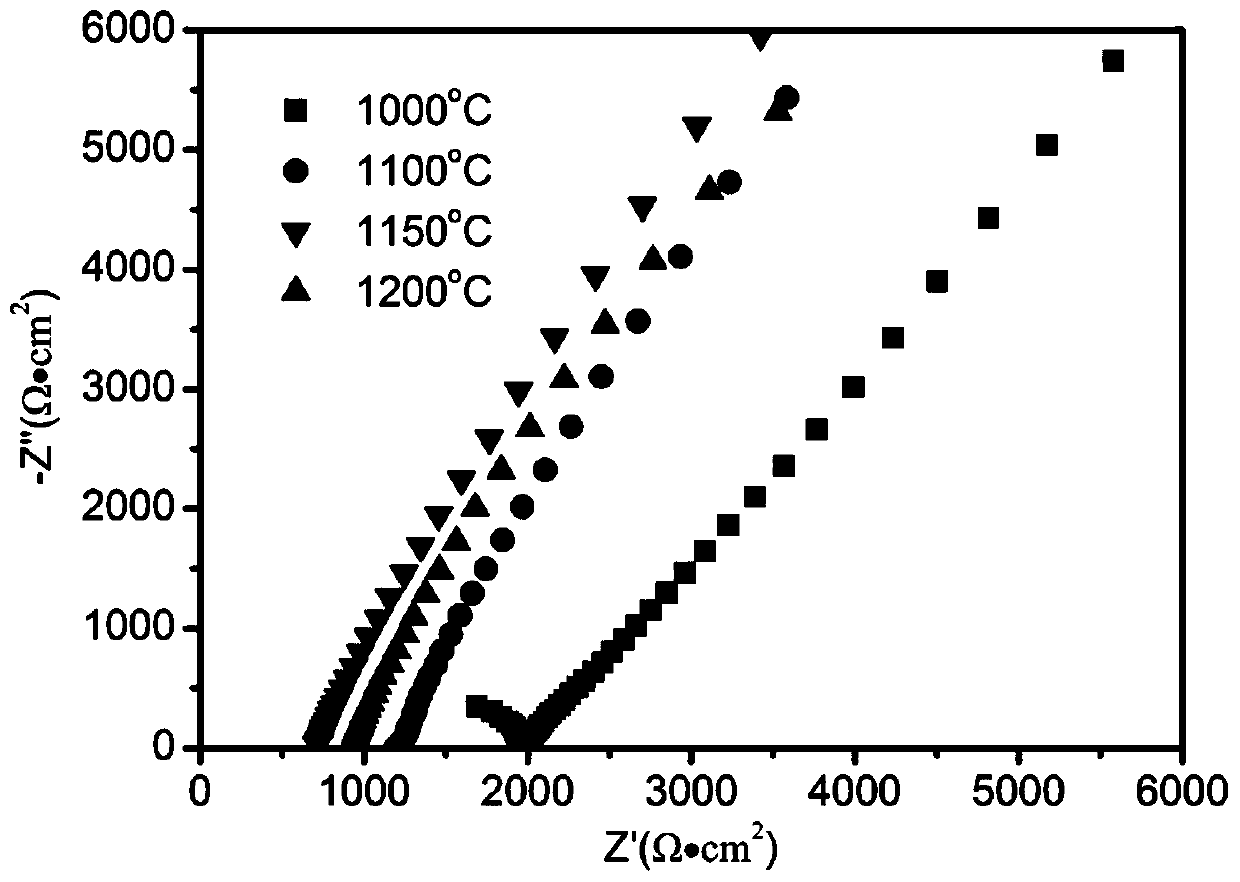

Embodiment 1

[0031] According to the stoichiometric ratio of the final product and an excess of 10% of the lithium source, lithium carbonate Li 2 CO 3 , Lanthanum Oxide La 2 o 3 , Zirconia ZrO 2 , niobium oxide Nb 2 o 5 and tantalum oxide Ta 2 o 5 Mix the powder evenly to obtain a mixed powder. The particle sizes of the five powders are 5 μm, 10 μm, 0.5 μm, 10 μm, and 10 μm, and then weigh about 10 g of the mixed powder and place it in a ball mill made of zirconia. 300%) isopropanol and an appropriate amount of zirconia balls for ball milling, the ball mill speed is 200 rpm, and the ball milling time is 12 hours. After ball milling, the mixed materials were put into a drying oven and dried at 80°C for 6 hours. Then pre-fired at 900°C for 4h, then ball milled and dried, weighed 3.0g of the dried mixture and put it into a mortar, added 0.3g (10%) of a 10% PVA aqueous solution, ground for 15 minutes, and then the mixture The material is placed in a steel mold, and the green body is o...

Embodiment 2

[0034] According to the stoichiometric ratio of the final product and an excess of 15% of the lithium source, lithium carbonate Li 2 CO 3 , Lanthanum Oxide La 2 o 3 , Zirconia ZrO 2 , niobium oxide Nb 2 o 5 and tantalum oxide Ta 2 o 5 Mix the powder evenly to obtain a mixed powder. The particle sizes of the five powders are 10 μm, 10 μm, 1 μm, 10 μm, and 5 μm, and then weigh about 10 g of the mixed powder and place it in a ball mill made of zirconia. Add 20 g (200% ) isopropanol and an appropriate amount of zirconia balls for ball milling, the ball mill speed is 200 rpm, and the ball milling time is 16 hours. After ball milling, the mixed material was put into a drying oven and dried at 80°C for 12 hours. Then pre-fired at 1100°C for 1h, then ball milled and dried, weighed 3.0g of the dried mixture and put it into a mortar, added 0.3g (10%) of a 15% PVA aqueous solution, ground for 15 minutes, and then the mixture The material is placed in a steel mold, and the green ...

Embodiment 3

[0036] According to the stoichiometric ratio of the final product and an excess of 12% of the lithium source, lithium carbonate Li 2 CO 3 , Lanthanum Oxide La 2 o 3 , Zirconia ZrO 2 , niobium oxide Nb 2 o 5 and tantalum oxide Ta 2 o 5 Mix the powder evenly to obtain a mixed powder. The particle sizes of the five powders are 10 μm, 10 μm, 0.5 μm, 10 μm, and 10 μm. Then weigh about 10 g of the mixed powder and place it in a ball mill made of zirconia. Add 20 g (200 %) isopropanol and an appropriate amount of zirconia balls for ball milling, the ball mill speed is 300 rpm, and the ball milling time is 24 hours. After ball milling, the mixed material was put into a drying oven and dried at 80°C for 10 hours. Then pre-fired at 900°C for 4h, then ball milled and dried, weighed 3.0g of the dried mixture and put it into a mortar, added 0.3g (10%) of a 12% PVA aqueous solution, ground for 15 minutes, and then the mixture The material is placed in a steel mold, and the green bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com