Composite rubber-plastic all-season heat preservation and insulation quilt for greenhouses

A thermal insulation and composite technology, applied in the field of thermal insulation materials, can solve the problems of shortening the service life of the whole shed quilt, easy aging and delamination, and reducing the thermal insulation performance, so as to prolong the good use condition and service life, and improve the effect of supplementary light. , the effect of increasing the thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

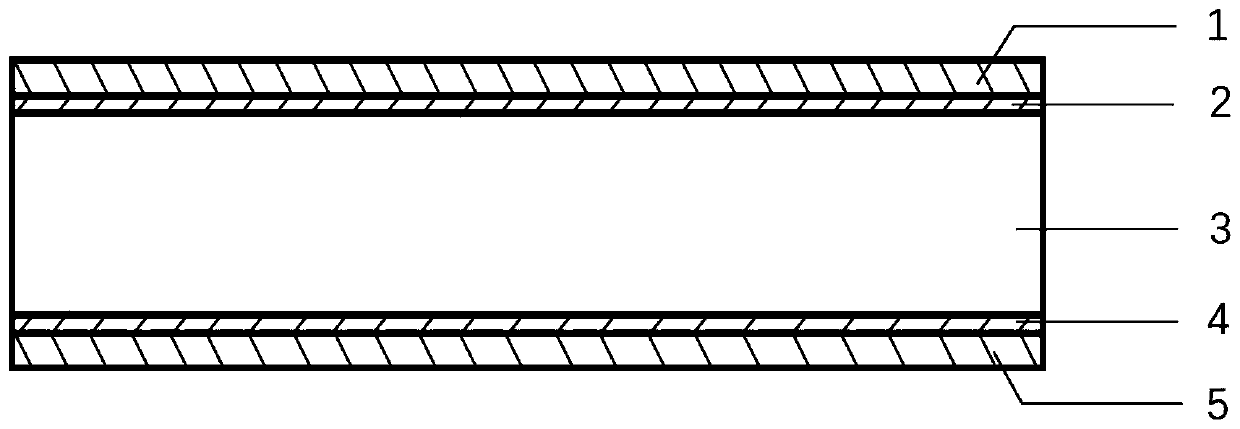

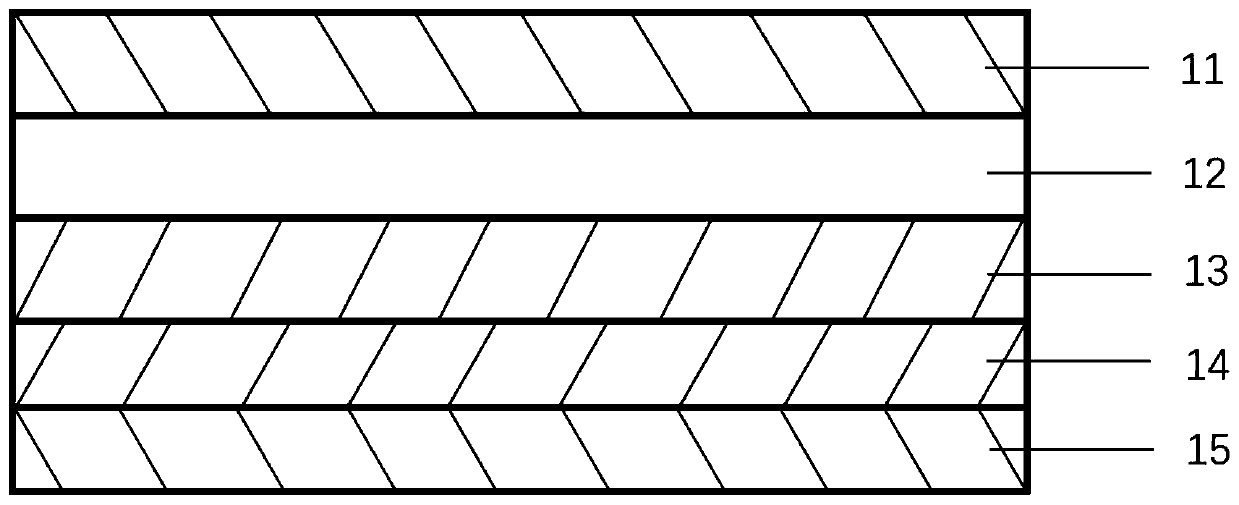

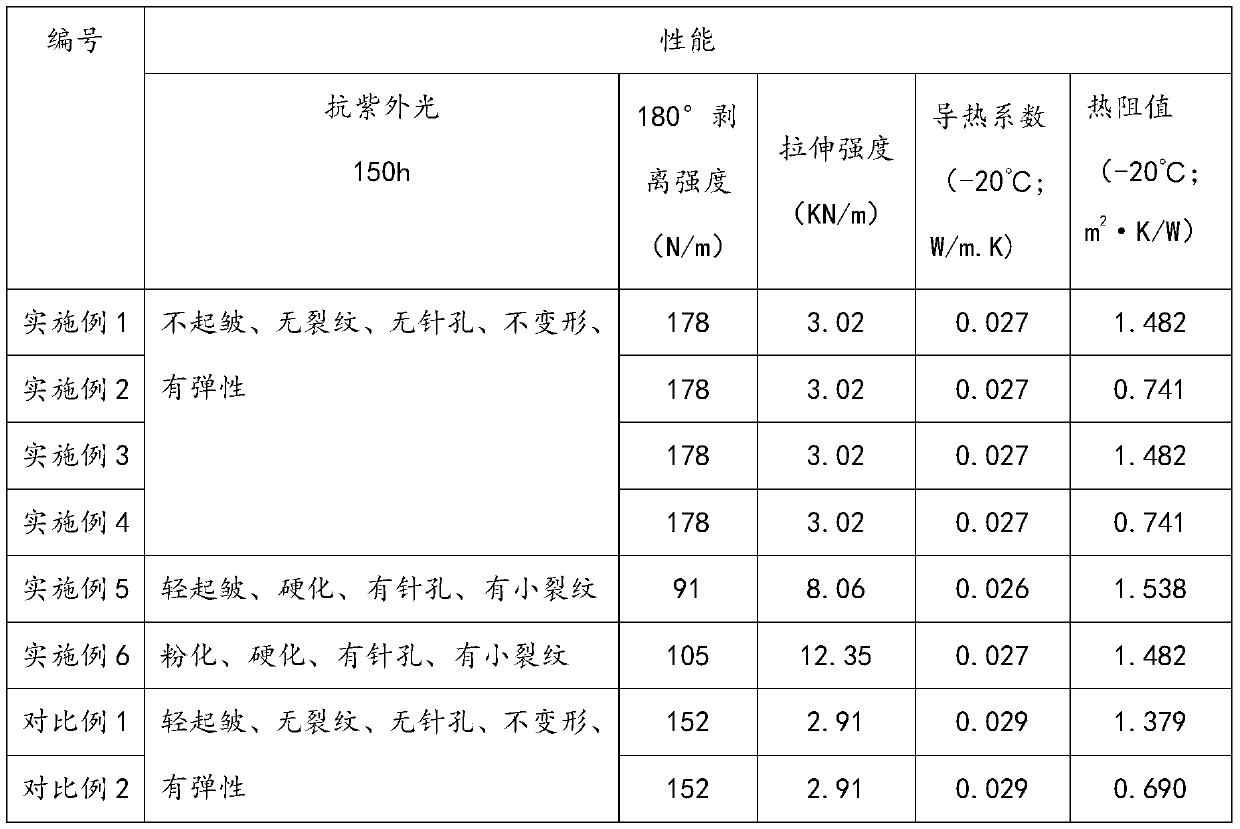

[0030] Adopt the formula of CN 201310038429.5 Example 1 to prepare the rubber-plastic insulation core material 3, the upper surface layer 1 of the rubber-plastic shed quilt is a five-layer co-extruded anti-aging polyethylene film facing outwards in black, and the lower surface layer 5 of the rubber-plastic shed quilt is white facing outwards Five-layer co-extruded anti-aging polyethylene film. The upper and lower surface layers of the rubber-plastic shed quilt are five-layer co-extruded anti-aging polyethylene film, that is, the upper and lower surface layers of the rubber-plastic shed quilt are: the first layer of anti-aging transparent heat-sealing film layer 11, the anti-ultraviolet black film light-blocking layer 12, the first layer Anti-aging opalescent film reflective layer 13, second anti-aging opalescent film reflective layer 14, second anti-aging transparent heat-sealing film layer 15. The five-layer co-extrusion film is the surface protection material, and the thickn...

Embodiment 2

[0032] The same composite rubber-plastic four-season greenhouse heat insulation quilt as in Example 1 is used, the difference is that the thickness of the rubber-plastic coil is 2cm, the thickness of the five-layer co-extrusion film is 0.15mm, and the width of the heat-sealing tape is about 10cm. The performance test data are listed in Table 1.

Embodiment 3

[0034] The same composite rubber-plastic four-season greenhouse thermal insulation quilt as in Example 1 is used, the difference is that the upper surface layer 1 of the rubber-plastic greenhouse is a five-layer co-extruded anti-aging polyethylene film facing outwards, that is, the rubber-plastic greenhouse The upper surface layer of the quilt is: the second layer of anti-aging transparent heat-sealing film layer 15, the second layer of anti-aging opalescent film reflective layer 14, the first layer of anti-aging opalescent film reflective layer 13, the anti-ultraviolet black film light-blocking layer 12, the first layer Anti-aging transparent heat-sealing film layer 11. The five-layer co-extrusion film is the surface protection material, the thickness of the rubber and plastic coil is 4cm, the thickness of the five-layer co-extrusion film is 0.15mm, and the width of the heat-sealing tape is about 10cm. The performance test data are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com