Method for obtaining porous zirconium dioxide thermal insulation ceramic through shaddock peel

A technology of zirconium dioxide and grapefruit peel is applied in the field of refractory materials, which can solve the problems of complicated operation and high cost, and achieve the effect of uniform voids, simple method and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

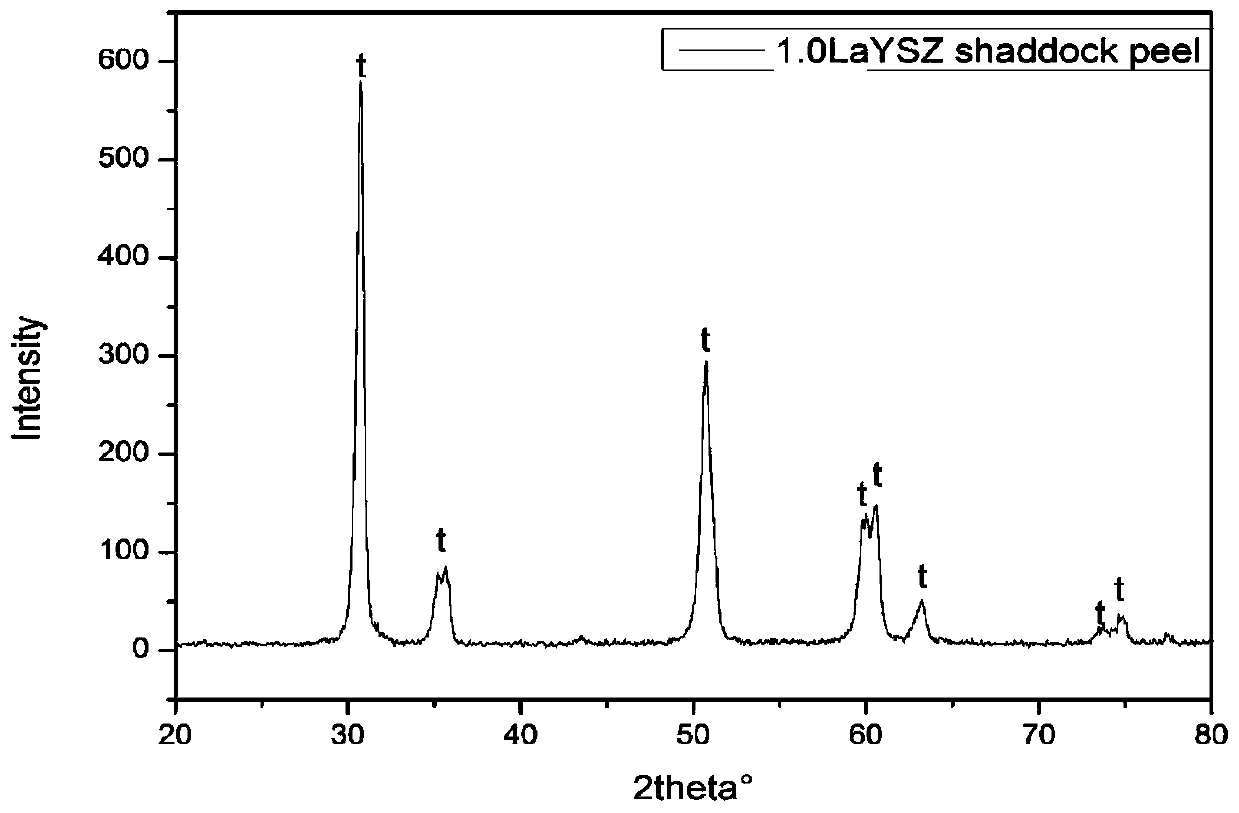

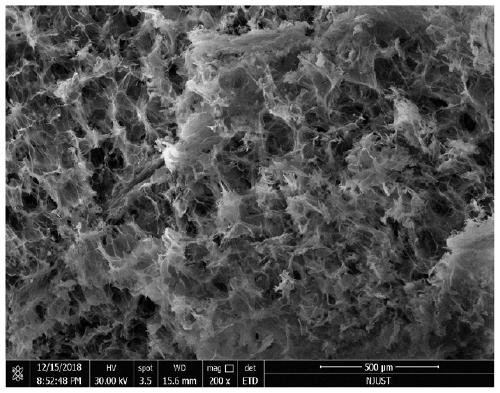

[0027] Take 0.25 g of yttrium nitrate hexahydrate, 0.037 g of lanthanum carbonate and 2.5 g of zirconium oxychloride octahydrate and dissolve them in 50 ml of 50vol% ethanol solution. Immerse the dried grapefruit peel in the solution, squeeze it dry after soaking for 5 minutes, take it out and dry it; raise the dried grapefruit peel to 1000°C at a heating rate of 5°C / min, and keep it warm for 1h to prepare porous carbon dioxide. Zirconium ceramics. figure 1 It is the XRD phase of tetragonal zirconia; figure 2 It is a microscopic SEM characterization of porous ceramics at low concentrations, and it can be seen that the ceramic pore walls are relatively thin.

Embodiment 2

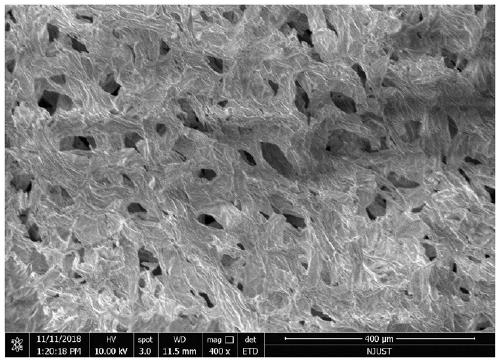

[0029] Take 0.40g of yttrium nitrate hexahydrate, 0.05g of lanthanum carbonate, and 4.0g of zirconium oxychloride octahydrate and dissolve them in 20 ml of 50vol% ethanol solution. The dried grapefruit peel was immersed in the solution, soaked for 5 minutes, squeezed dry, taken out and dried; the dried grapefruit peel was raised to 1400°C at a heating rate of 5 minutes, and kept for 1 hour to prepare porous zirconia ceramics. The thermal conductivity of the zirconia porous ceramic prepared by this method is 0.2116 (hot surface 1000°C), and the thermal conductivity of the dense zirconia plate is 0.2834. In comparison, the thermal insulation performance has been improved by about 25%. image 3 , 4 SEM characterization of the zirconia porous ceramics prepared at this concentration shows a clear porous and connected structure.

Embodiment 3

[0031] Take 1.20g of yttrium nitrate hexahydrate, 0.15g of lanthanum carbonate, and 12g of zirconium oxychloride octahydrate and dissolve them in 40 ml of 50vol% ethanol solution. Immerse the dried grapefruit peel in the solution, squeeze it dry after soaking for 5 minutes, take it out and dry it; raise the temperature of the dried grapefruit peel to 1400°C at a rate of 5°C / min, and keep it warm for 1 hour to prepare a porous bismuth. Zirconia ceramic. Figure 5 It is the zirconia porous ceramics prepared under this condition. Obviously, with the increase of concentration and temperature, the morphology of the prepared porous structure is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com