High-performance wave-absorbing material core-shell structure CoxFe3-xO4@MoS2 nano-composite and synthesis method thereof

A coxfe3-xo4, nanocomposite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as gaps, and achieve the effects of good absorbing performance, high selectivity, and thin matching thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

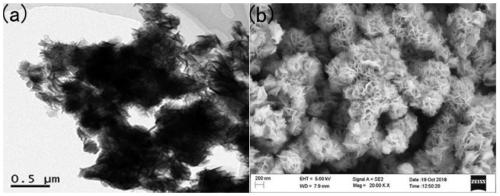

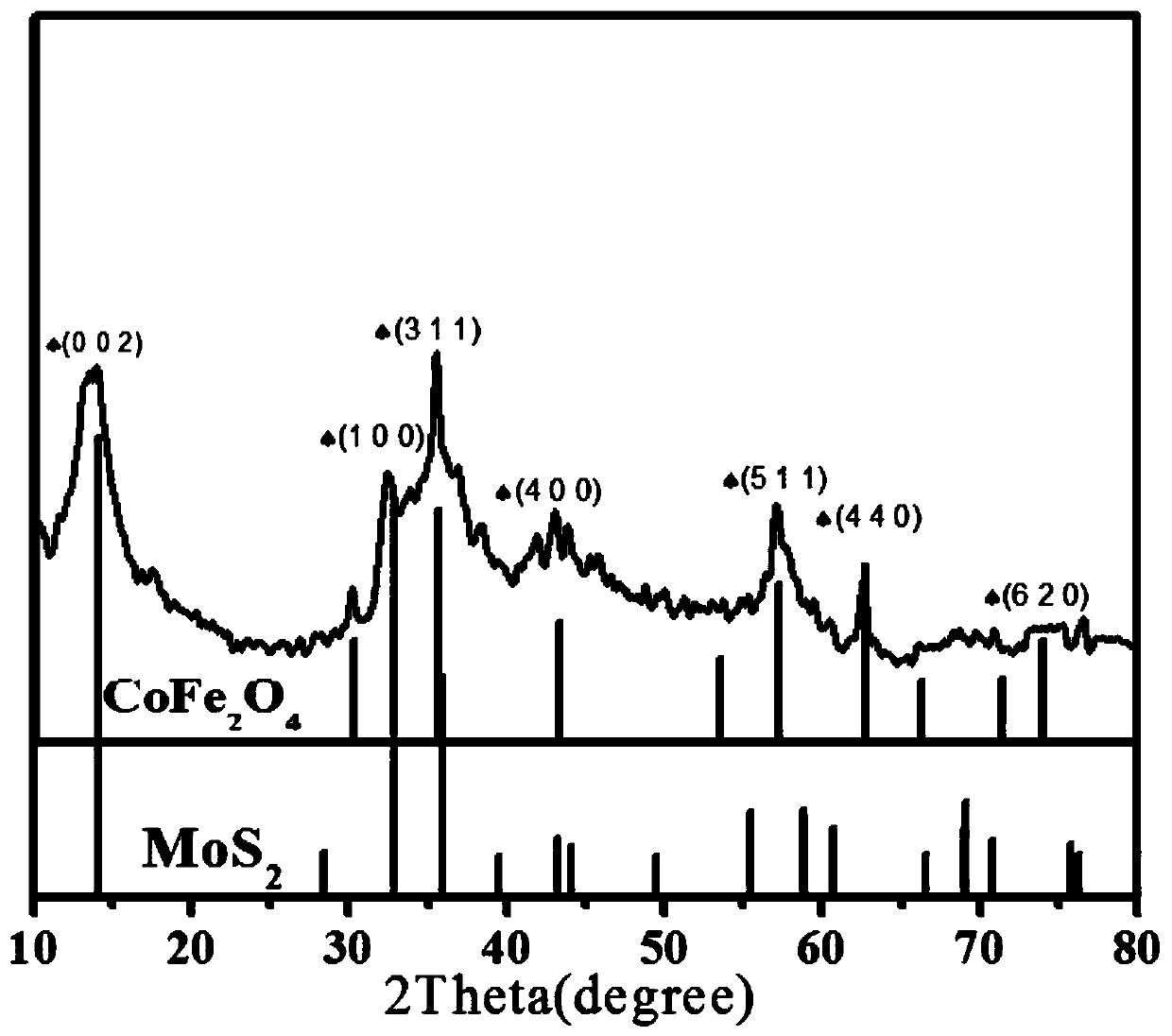

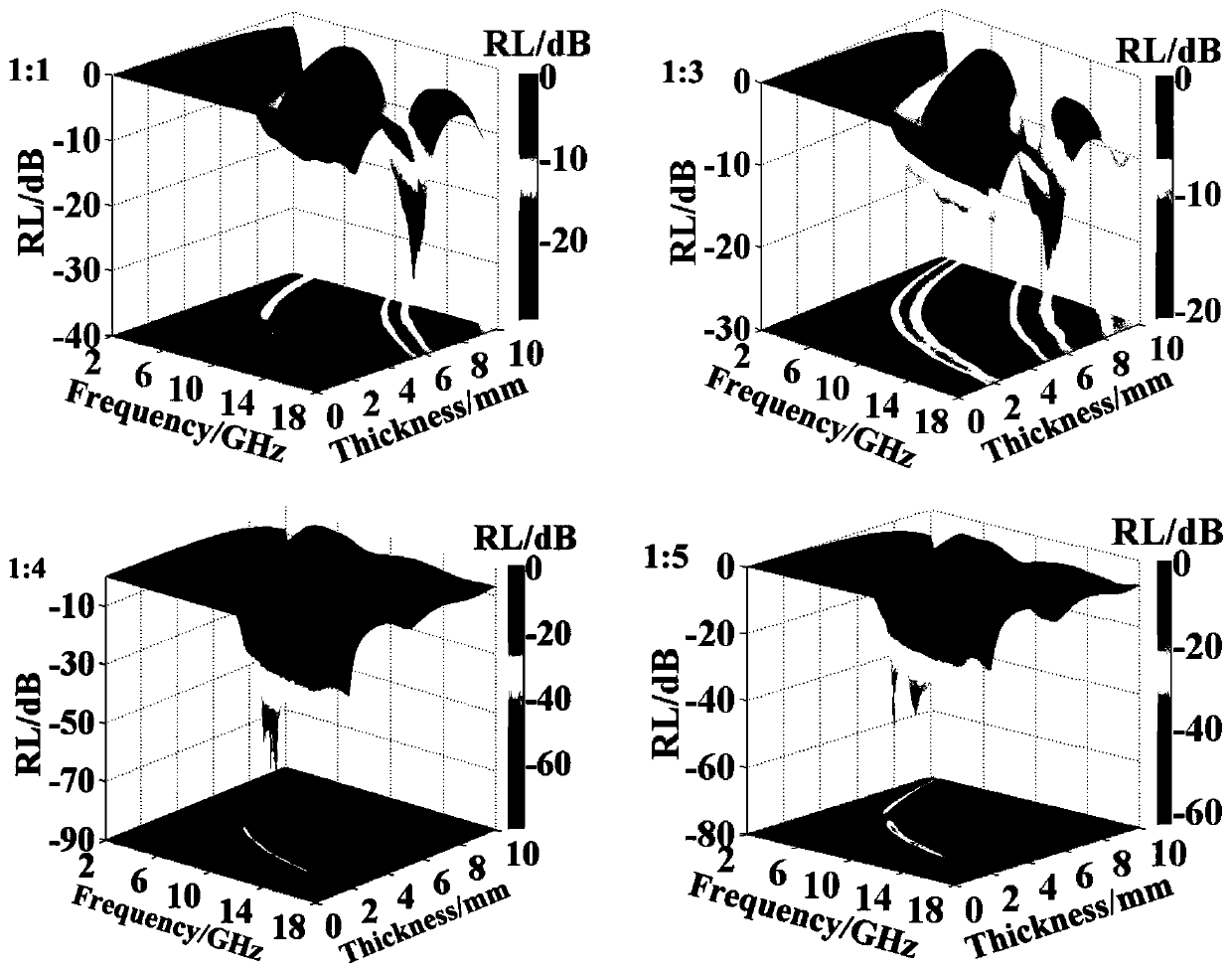

[0023] In the actual experiment, the inventors designed and synthesized the core-shell structure Co with different atomic ratios of Co:Fe molar ratios of 1:1, 1:2, 1:3, 1:4 and 1:5. x Fe 3-x o 4 @MoS 2 nanocomposite. The specific synthesis process is based on Co with a molar ratio of Co:Fe of 1:4. 0.6 Fe 2.4 o 4 @MoS 2 Nanocomposites are elaborated as an example. The experimental process is mainly completed in two steps:

[0024] In the first step, Co was synthesized by hydrothermal method 0.6 Fe 2.4 o 4 Nanoparticles as a precursor: 0.249 g of cobalt acetate tetrahydrate (C 4 h 6 CoO 4 4H 2 O) and 1.08g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) ultrasonically dissolve in 30 mL of ethylene glycol solution; then, add 0.9 g of urea to the above-mentioned solution, and after fully dissolving, pour the resulting mixed solution into a reaction kettle, and keep the temperature at 200° C. for 24 hours. Finally, after the whole device is cooled to room temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com