Soft moisture-absorbing curly short fiber and preparation method and application thereof

A short fiber and crimping technology, which is applied in the field of fiber, soft and hygroscopic curly short fiber and its preparation, can solve the problems of low moisture absorption, difficult spinning, poor cohesion, etc., and achieve the effect of easy crimping, improving yield and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

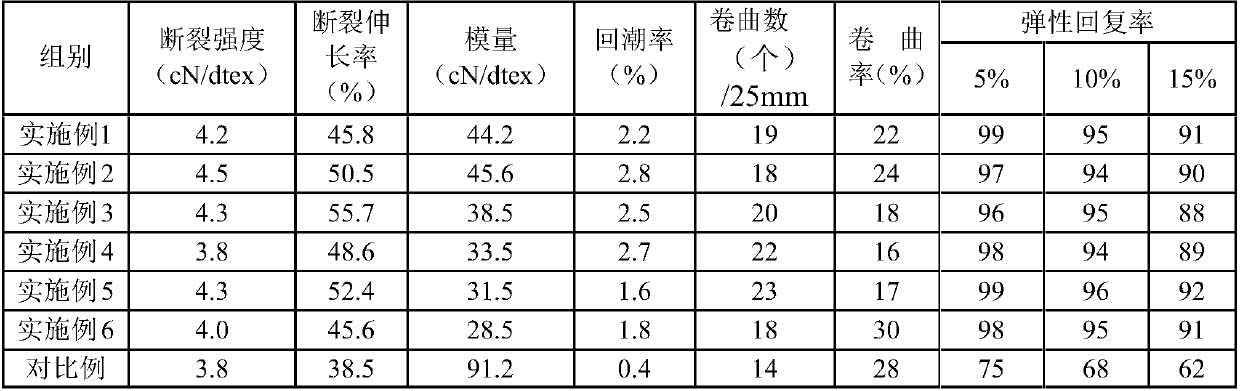

Examples

Embodiment 1

[0051] The preparation method of the soft moisture-absorbing crimped staple fiber of this embodiment is as follows:

[0052] 1) The polyamide 56 melt and the polyethylene terephthalate melt are merged in the composite spinning assembly through the respective melt pipelines, and extruded through the eccentric composite spinneret, and cooled to form the spun yarn;

[0053] Among them, the ratio of skin-core components is accurately adjusted by a metering pump, the content of polyamide 56 in the skin layer is 25% by weight, and the content of polyethylene terephthalate in the core layer is 75% by weight;

[0054] The number of holes in the eccentric composite spinneret is 800f, the hole diameter of the spinneret is 0.25mm, the stretch ratio of the spinneret is 80, the cooling method is ring blowing cooling, the ring blowing temperature is 24℃, and the ring blowing speed is 0.8m / s.

[0055] 2) Post-processing the above-mentioned nascent silk to obtain soft moisture-absorbing crimped stap...

Embodiment 2

[0067] The preparation method of the soft moisture-absorbing crimped staple fiber of this embodiment is as follows:

[0068] 1) The polyamide 56 melt and the polytrimethylene terephthalate melt are merged in the composite spinning assembly through the respective melt pipes, and are extruded through the parallel composite spinneret and cooled to form the spun yarn;

[0069] Among them, the proportion of parallel components is accurately adjusted by a metering pump, the content of the first parallel component polyamide 56 is 50wt%, and the content of the second parallel component polytrimethylene terephthalate is 50wt%;

[0070] The number of holes in the parallel composite spinneret is 1000f, the diameter of the spinneret is 0.3mm, the stretch ratio of the spinneret is 100, the cooling method is ring blowing cooling, the ring blowing temperature is 25℃, and the ring blowing speed is 0.9m / s.

[0071] 2) Post-processing the above-mentioned nascent silk to obtain soft moisture-absorbing ...

Embodiment 3

[0077] The preparation method of the soft moisture-absorbing crimped staple fiber of this embodiment is as follows:

[0078] 1) The polyamide 56 melt and the polybutylene terephthalate melt are merged in the composite spinning assembly through the respective melt pipes, and are extruded through the parallel composite spinneret and cooled to form the spun yarn;

[0079] Among them, the proportion of parallel components is accurately adjusted by a metering pump, the content of the first parallel component polyamide 56 is 40wt%, and the content of the second parallel component polybutylene terephthalate is 60wt%;

[0080] The number of holes in the parallel composite spinneret is 700f, the diameter of the spinneret is 0.28mm, the stretching ratio of the spinneret is 80, the cooling method is ring blowing cooling, the ring blowing temperature is 23℃, and the ring blowing speed is 0.8m / s.

[0081] 2) Post-processing the above-mentioned nascent silk to obtain soft moisture-absorbing crimpe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com