A kind of method and its application of rapid detection acid aldehyde content in oil

A technology for rapid determination of oleic acid, applied in the field of analysis and detection, can solve the problems of time-consuming accuracy and sensitivity, complex carbonyl valence derivatization, and tedious pretreatment, and achieves the effects of reliable and high results, fast reaction speed, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

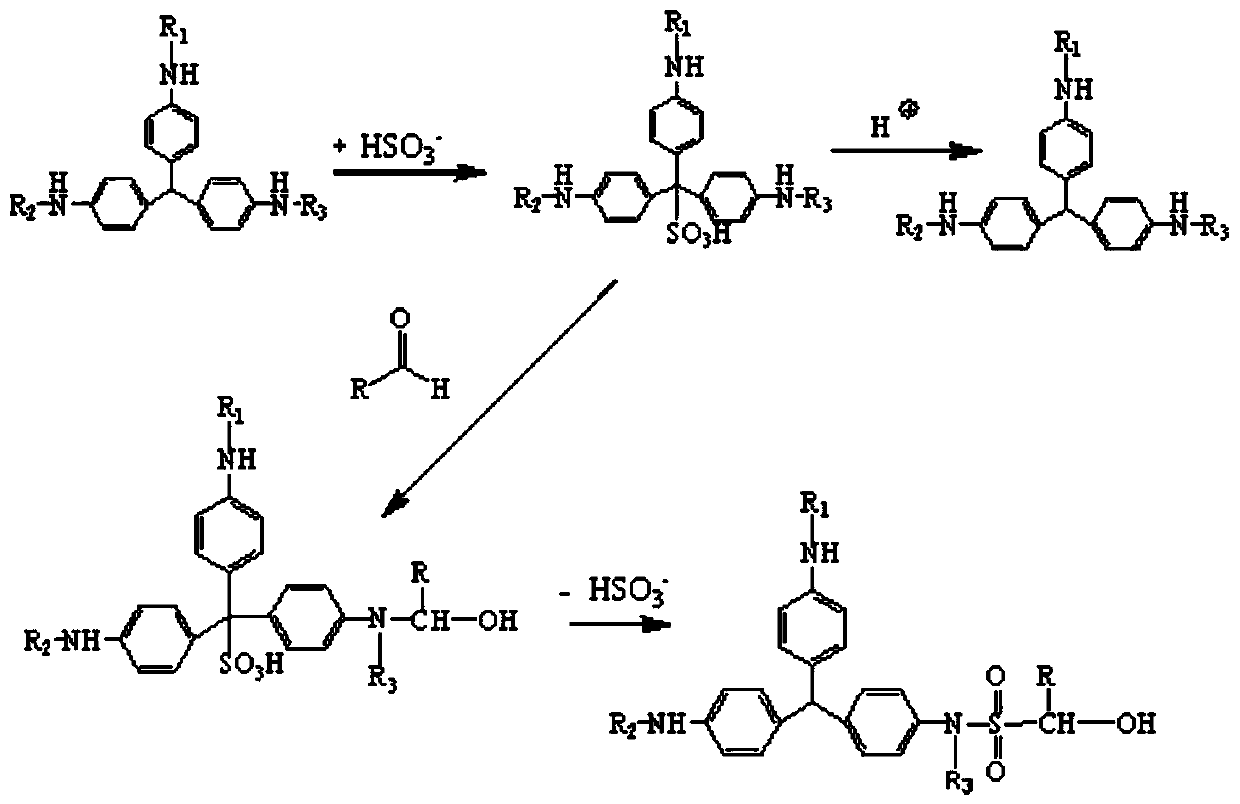

Method used

Image

Examples

Embodiment 1

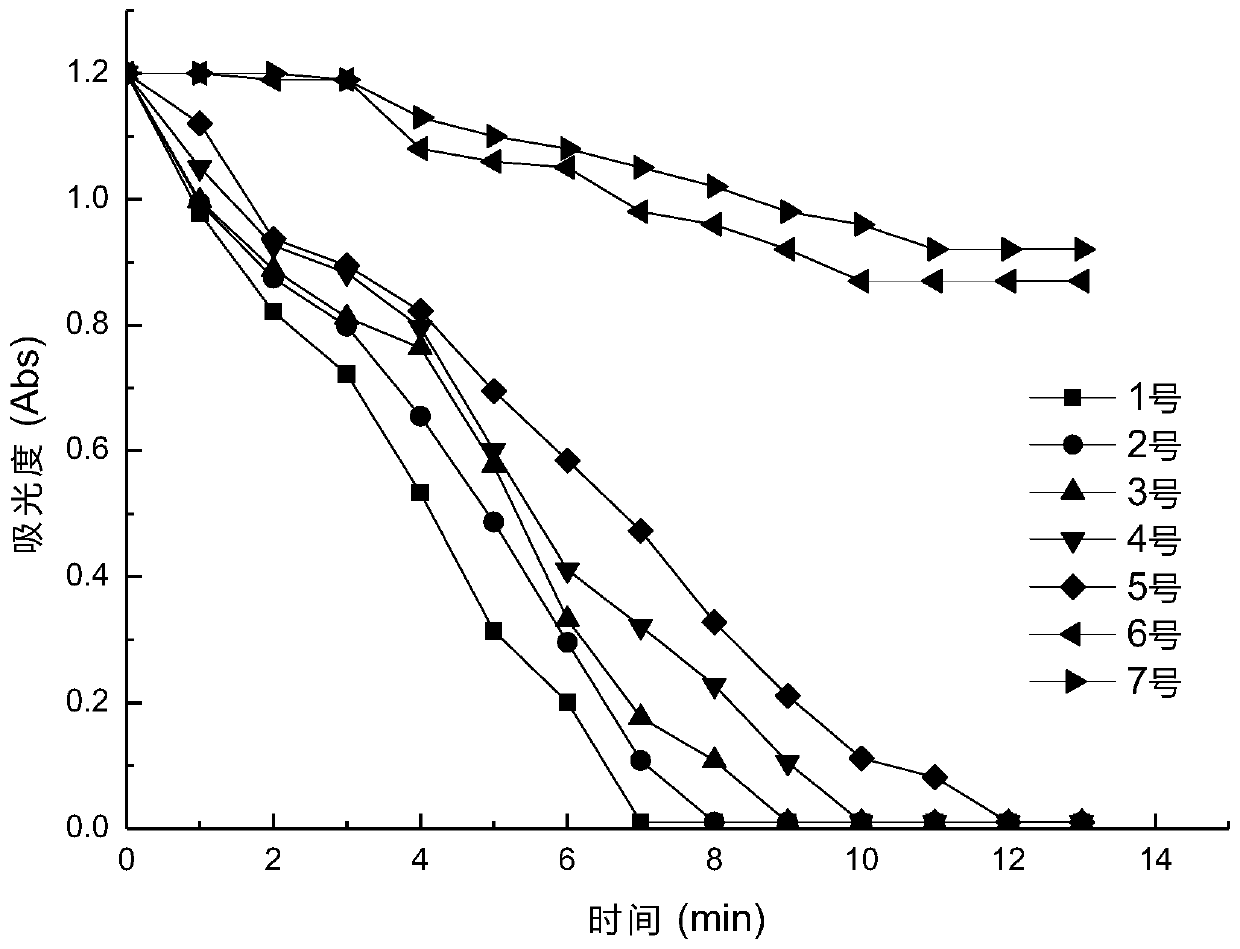

[0060] The ratio of embodiment 1 chromogenic agent and fading agent

[0061] Take seven 15mL colorimetric tubes, and number them as 1, 2, 3, 4, 5, 6, and 7, add 0.1mL, 2mM chromogenic reagent solution in each, and then add them to 1~7 colorimetric tubes in sequence Add 0.2mL of sodium bisulfite solution (discoloring agent, concentrations are 240mM, 120mM, 100mM, 80mM, 60mM, 40mM, 20mM), dilute to 10mL with ethanol, and measure the relationship between absorbance and time as figure 2 shown.

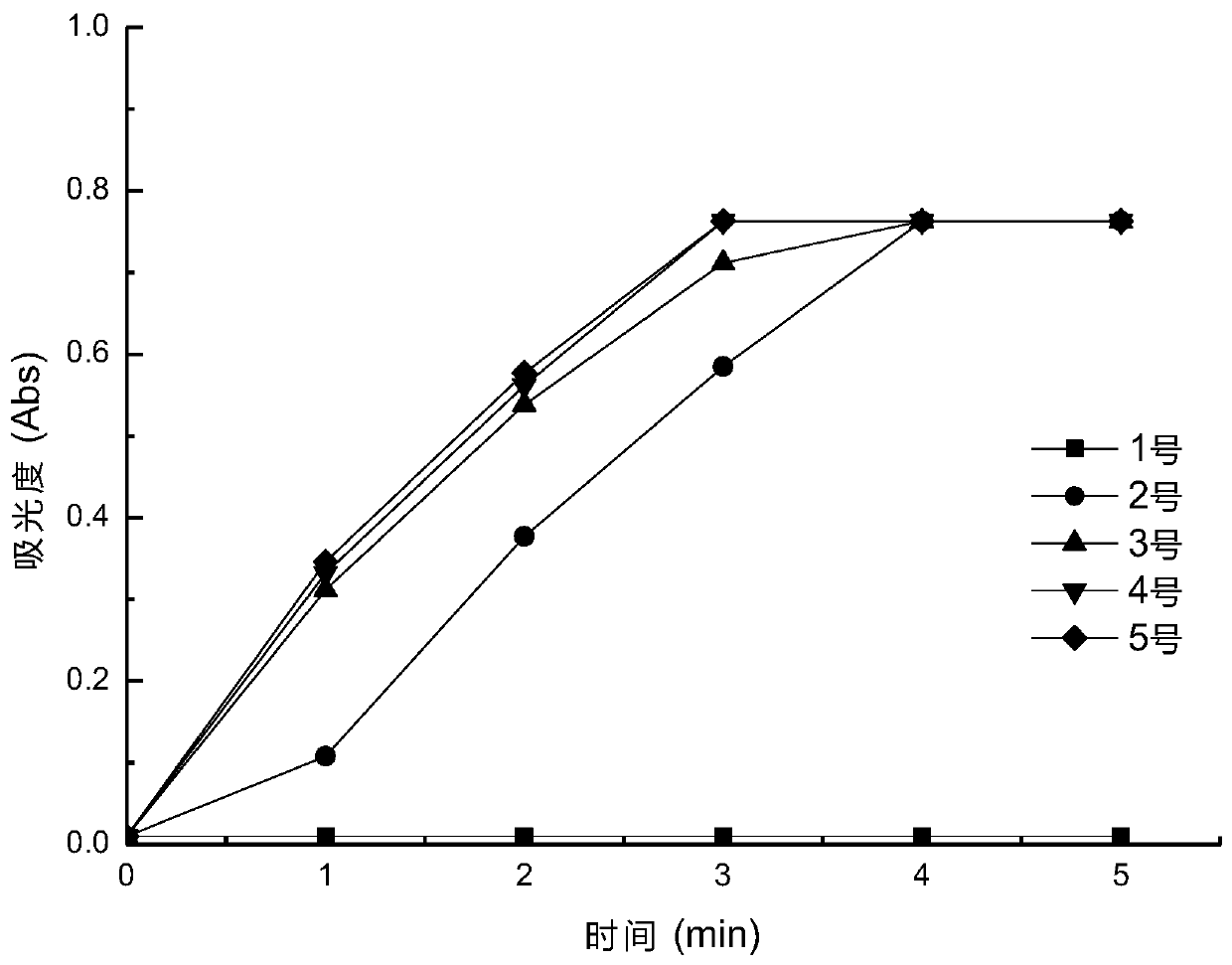

[0062] It can be seen that the greater the concentration of sodium bisulfite, the better the fading effect, and No. 6 and No. 7 cannot make the color developer fade because the concentration of sodium bisulfite is too low. After the color is completely faded, add the acid-aldehyde mixed solution to be a mixed solution of 60-2mM hydrochloric acid and hexanal, and observe the color development of the solution after fully reacting, such as image 3 As shown, it can be known that the No. 1 ...

Embodiment 2

[0063] The influence of embodiment 2 temperature on fading

[0064] Take 1mL, 2mM developer solution, add 2mL, 60mM sodium bisulfite solution to fade the color, and place them in water baths at 5, 10, 20, 25, 30, 35, 40, and 45°C in sequence. It can be found that when the temperature When the temperature is above 40°C, it can fade within 15 minutes. When the temperature is higher than 40°C, the stable structure obtained by the reaction of sodium bisulfite and the color developer will be destroyed and the color cannot be completely faded. Therefore, the color fading temperature is selected from 5 to 40°C, preferably from 5 to 30°C.

Embodiment 3

[0066] R in chromogen I 1 , R 2 , R 3 Both are H atoms, R 4 , R 5 , R 6 It is methyl, and the decolorizing agent is sodium bisulfite. After the color is completely faded, the standard curves of acid and aldehyde are respectively drawn at the maximum wavelength. Assay mixture standard curve was used for calibration. The standard curve equations for acids and aldehydes are as Figure 4 (a) and Figure 4 (b) shown.

[0067] Take 1-1.5g of almond oil oxidized at 120°C for different times, weigh it in a 10mL colorimetric tube, dilute to 2mL with chloroform, add 5mL of decolorization solution and 2mL of ethanol, and finally dilute to 10mL with chloroform. Measure the absorbance at 546nm and 494nm after developing color for 5min, and then according to Figure 4 Obtained standard curve, obtain almond oil respectively at 120 ℃, the change curve of acid and aldehyde content with time, such as Figure 5 shown.

[0068] At the same time, use the national standard titration meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com