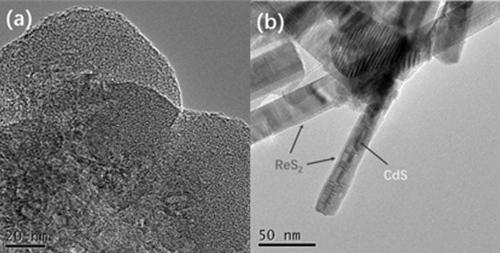

CdS nanorod@ few-layer ReS2 nanosheet composite photocatalyst

A nanosheet and nanorod technology, applied in the field of composite photocatalyst and preparation, can solve the problems of narrow solar spectral response and low photocatalytic efficiency, and achieve the effects of good process repeatability, large specific surface area and many active sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

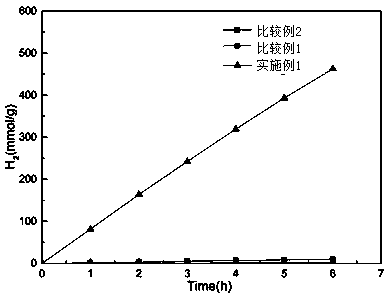

Embodiment 1

[0026] (1)ReS 2 Single crystal bulk as raw material, prepared ReS by ball milling 2 powder, the ball milling time is 8h, and the ball milling speed is 400rpm. Get ReS 2 powder dispersed in ethanol, where ReS 2 Powder quality: the volume of ethanol is about 1mg: 4ml; after that, it is sonicated in an ultrasonic machine, and the ultrasonication time is about 2h. After the above ultrasonic dispersion was left to stand for several hours, centrifuge at 4000rpm for 30min in a centrifuge to obtain the supernatant, then centrifuge the supernatant at 10000rpm for 30min to collect the precipitate attached on the centrifuge tube, pass the precipitate through ethanol and deionized water in turn Washed 3 times, then transferred to a Petri dish, and finally freeze-dried the nanosheets for several hours to form a uniformly dispersed few-layer ReS 2 Nanosheets.

[0027] (2) Cadmium acetate dihydrate (Cd(CH 3 COO) 2 2H 2 O) and dibenzyl disulfide (C 14 h 14 S 2) were ultrasonically ...

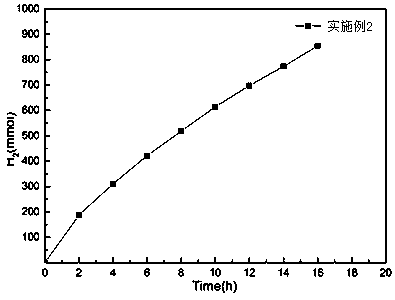

Embodiment 2

[0030] The difference from Example 1 is that the CdS supernatant layer and the few-layer ReS 2 The amount of nanosheets added meets ReS 2 The proportion of the final CdS nanorods @ReS 2 10% of the proportion of nanosheet composite photocatalyst.

Embodiment 3

[0032] The difference from Example 1 is that the CdS supernatant layer and the few-layer ReS 2 The amount of nanosheets added meets ReS 2 The proportion of the final CdS nanorods @ReS 2 20% of the proportion of nanosheet composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com