Efficient ozone water production machine

An ozone water machine and ozone water technology, applied in the direction of oxidized water/sewage treatment, deodorization, water treatment parameter control, etc., can solve the problems of difficult concentration control, pungent smell, human health damage, etc., to ensure the dissolution effect, The effect of reducing energy consumption and increasing the frequency of water replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

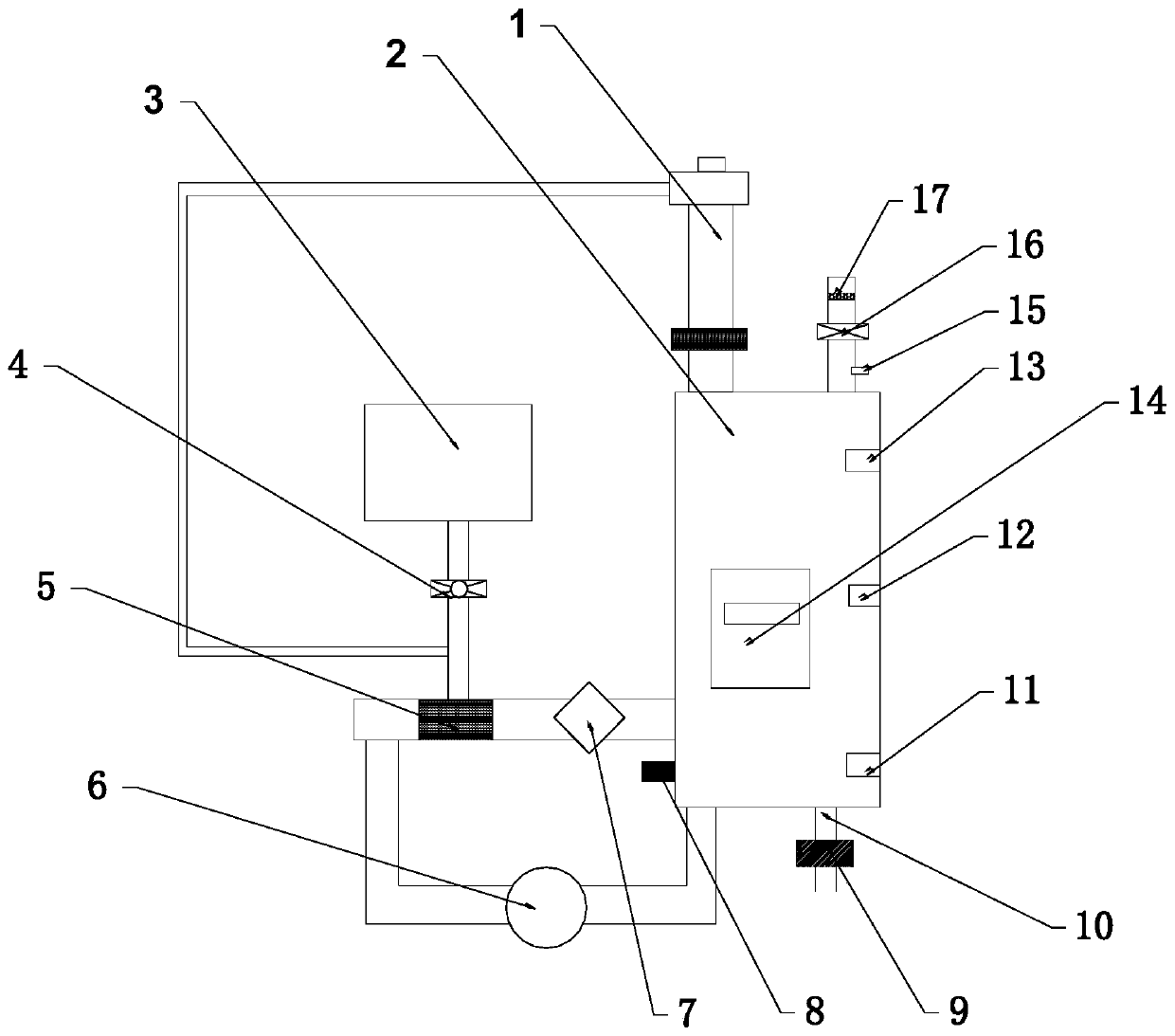

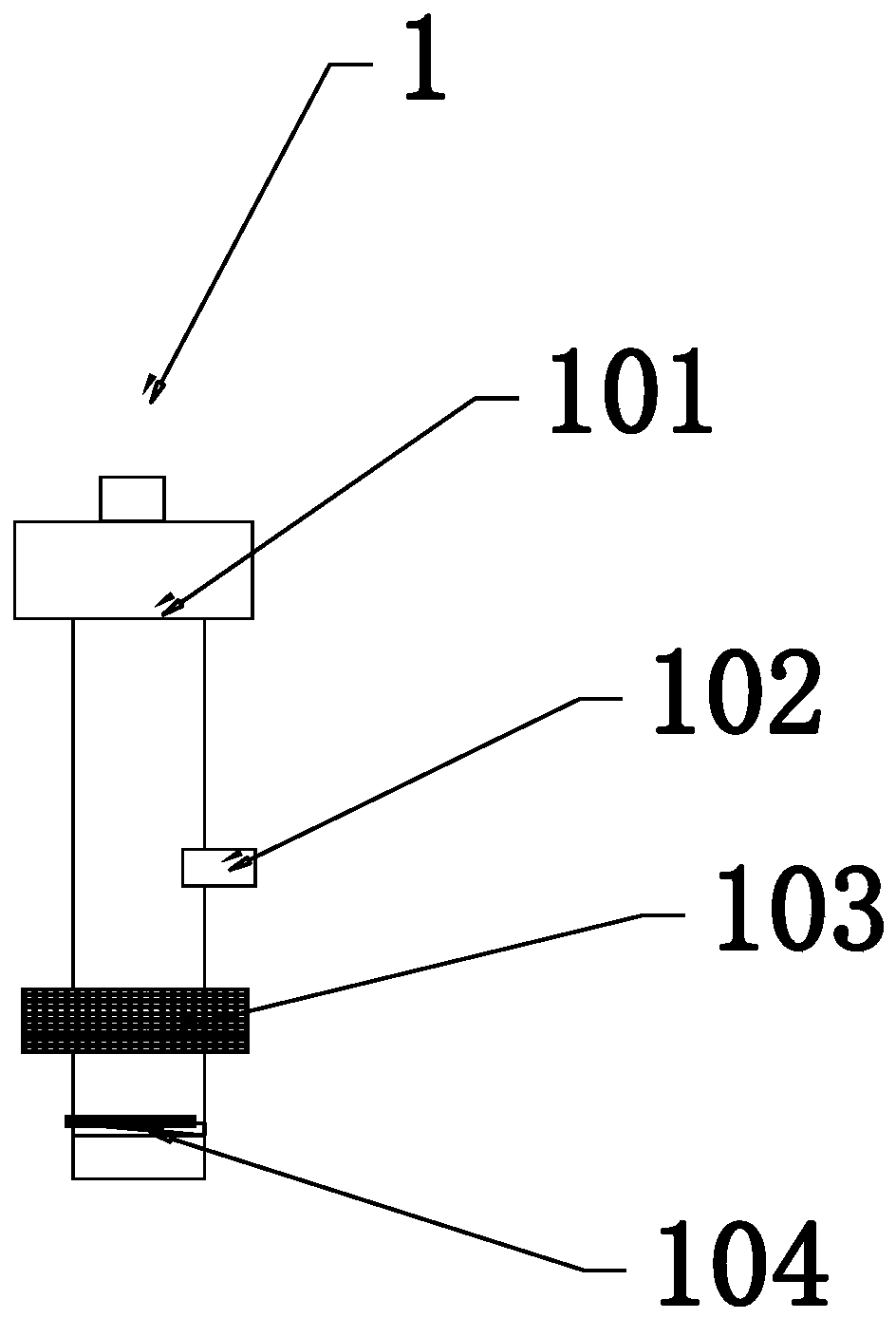

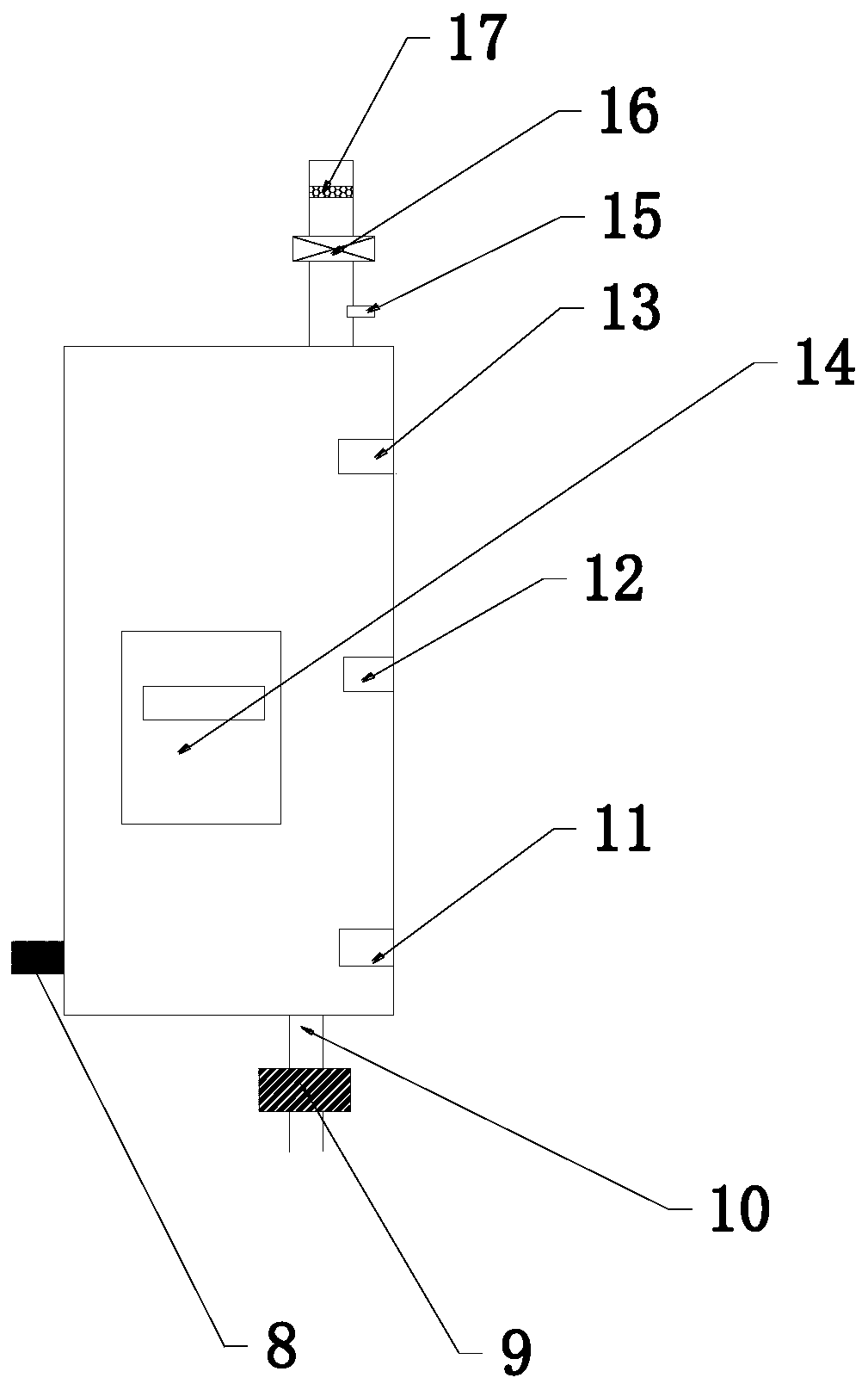

[0027] Such as Figure 1-3 As shown, a high-efficiency ozone water machine includes an ozone generator 3, an aerator 2, an ozonolysis device 1 and a controller 14, the ozonizer 3, the ozonolysis device 1 and the aerator 2 constitute an air supply pipeline, and the ozone The generator 3 and the aeration tank 2 are connected by pipes, the upper end of the aeration tank 2 is provided with an ozone decomposing device 1 and a water replenishing solenoid valve 16, the upper end of the water replenishing solenoid valve 16 is provided with a filter element 17, and the lower end of the water replenishing solenoid valve 16 is provided with a water flow meter 15, On the connecting pipeline of the ozone generator 3 and the aeration cylinder 2, a one-way valve 4, a Venturi mixer 5 and a gas-liquid mixer 7 are successively arranged, and the one-way valve 4 is arranged at the outlet end of the ozone generator 3, and the ozonolysis device 1 The output end is connected to the output end of the...

Embodiment 2

[0032] Such as Figure 1-2 As shown, a high-efficiency ozone water machine includes an ozone generator 3, an aerator 2, an ozonolysis device 1 and a controller 14, the ozonizer 3, the ozonolysis device 1 and the aerator 2 constitute an air supply pipeline, and the ozone The generator 3 and the aeration tank 2 are connected by pipes, and the upper end of the aeration tank 2 is provided with an ozone decomposition device 1 and a water replenishing solenoid valve 16, and the connecting pipe between the ozone generator 3 and the aeration tank 2 is provided with a one-way valve 4 and a Venturi valve in sequence. Mixer 5 and gas-liquid mixer 7, check valve 4 is located at the outlet of ozone generator 3, and the output end of ozonolysis device 1 is connected with the output end of check valve 4, the input end of Venturi mixer 5, exposure The lower end of the air cylinder 2 and the side close to the ozone generator 3 are provided with a circulation pump 6, one end of the circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com