High-hardness gray cast iron and smelting method thereof

A gray cast iron, high hardness technology, applied in the field of casting, can solve the problems of poor mechanical properties, flaky graphite splitting, stress concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

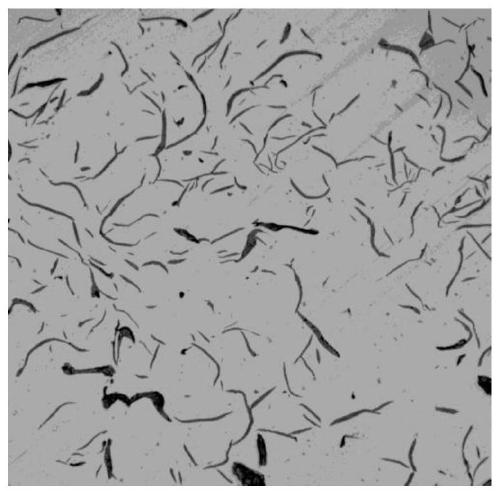

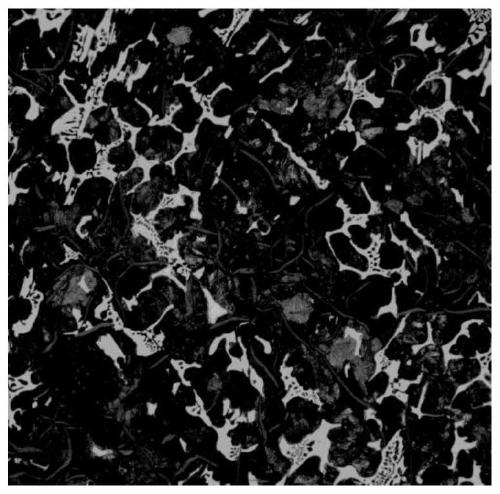

Image

Examples

Embodiment 1

[0020] According to the technology of the present invention to smelt the gray cast iron molten metal needed for the gray cast iron parts, the details are as follows:

[0021] 1) Take by weighing 3% pig iron, 62% steel scrap, 30% mechanical iron and 1.6% ferrosilicon of molten metal with an electronic scale, and the total weight of the molten metal is determined according to the process yield of the casting; For this embodiment, about 3.3 tons of gray cast iron molten metal needs to be smelted, and 99 kg of pig iron Z18, 2.046 tons of steel scrap, 990 kg of mechanical iron and 52.8 kg of ferrosilicon are required.

[0022] 2) After cleaning the intermediate frequency electric furnace, pour the steel scrap that has been weighed into the electric furnace for smelting. After the steel scrap is completely melted, add the machine iron that has been weighed and continue smelting until the machine iron is completely melted Finally, add the weighed pig iron, and keep the temperature of...

Embodiment 2

[0032] According to the technology of the present invention to smelt the gray cast iron molten metal needed for the gray cast iron parts, the details are as follows:

[0033] 1) Take by weighing 3% pig iron, 60% steel scrap, 28% mechanical iron and 1.5% ferrosilicon of molten metal with an electronic scale, and the total weight of the molten metal is determined according to the process yield of the casting; For this embodiment, about 3.3 tons of gray cast iron molten metal needs to be smelted, and 99 kg of pig iron Z18, 1.98 tons of steel scrap, 924 kg of mechanical iron and 49.5 kg of ferrosilicon are required.

[0034] 2) After cleaning the intermediate frequency electric furnace, pour the steel scrap that has been weighed into the electric furnace for smelting. After the steel scrap is completely melted, add the machine iron that has been weighed and continue smelting until the machine iron is completely melted Finally, add the weighed pig iron, and keep the temperature of ...

Embodiment 3

[0043] According to the technology of the present invention to smelt the gray cast iron molten metal needed for the gray cast iron parts, the details are as follows:

[0044]1) take by weighing 3.5% pig iron, 64% steel scrap, 32% machine iron and 1.7% ferrosilicon of molten metal gross weight with electronic scale, and the gross weight of described molten metal is determined according to the process yield rate of casting; For this embodiment, about 3.3 tons of gray cast iron molten metal needs to be smelted, and 115.5 kg of pig iron Z18, 2.112 tons of steel scrap, 1.056 tons of mechanical iron and 56.1 kg of ferrosilicon are required.

[0045] 2) After cleaning the intermediate frequency electric furnace, pour the steel scrap that has been weighed into the electric furnace for smelting. After the steel scrap is completely melted, add the machine iron that has been weighed and continue smelting until the machine iron is completely melted Finally, add the weighed pig iron, and k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com