Preparation method for quick-electric-heating graphene fabric

A graphene and electric heating technology, which is applied in the direction of ohmic resistance heating, electric heating devices, heating element materials, etc., can solve the problems of further improvement of comfort, cumbersome preparation process, and insufficient integration, and achieve simple and economical preparation methods. Improved integration and comfort, and excellent safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

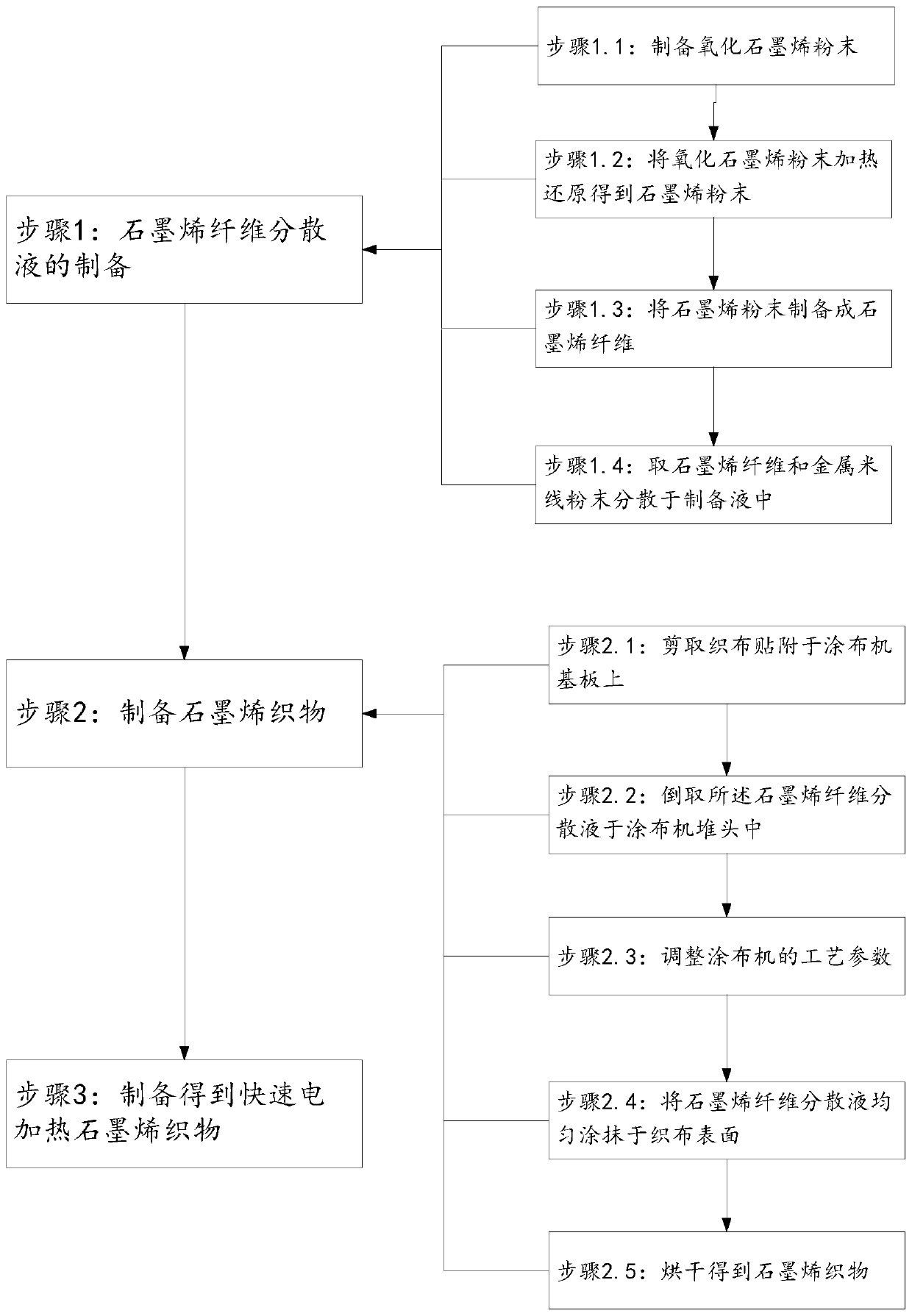

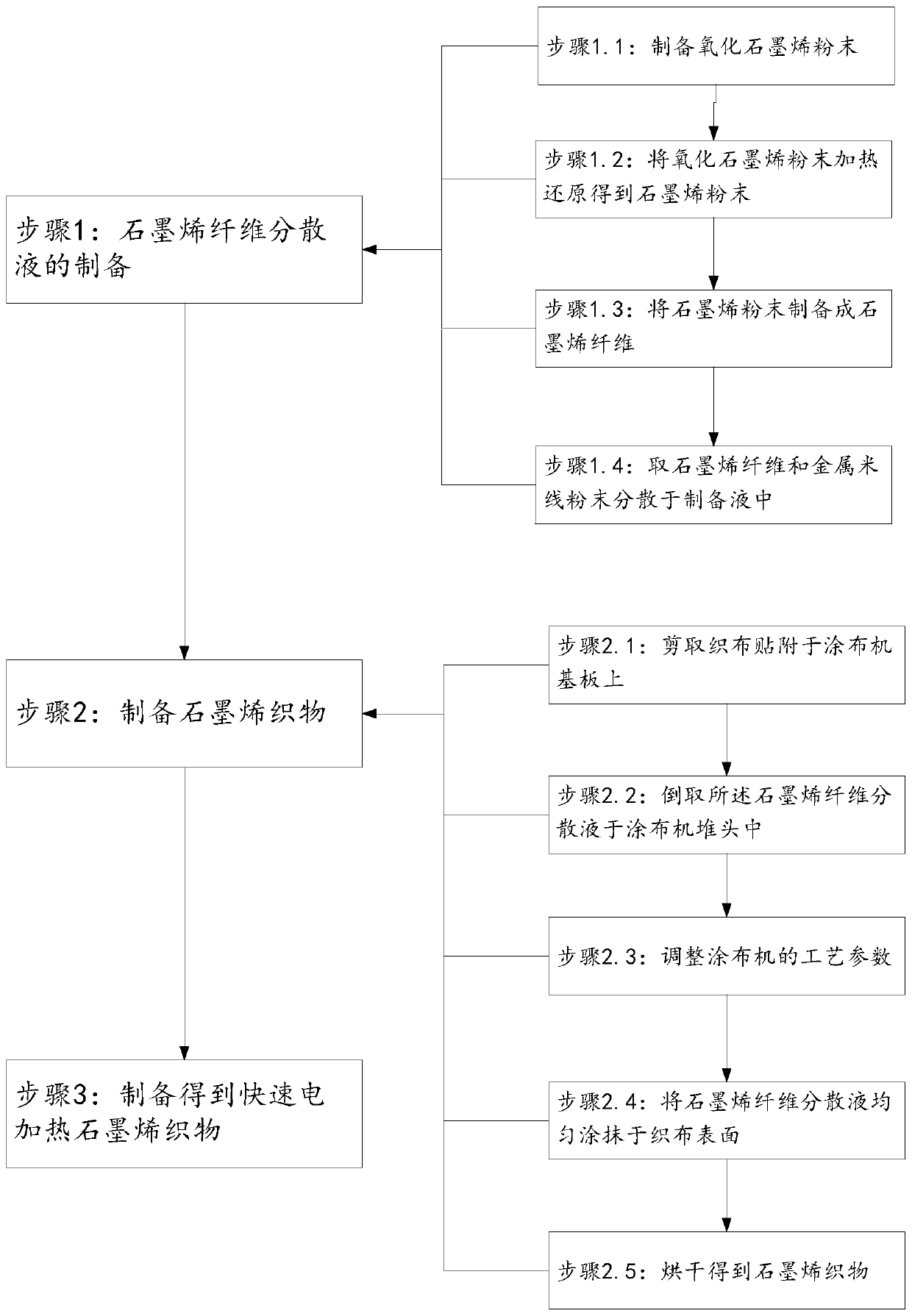

[0043] Such as figure 1 and figure 2 Shown, the present invention proposes a kind of preparation method of fast electric heating graphene fabric, comprises the following steps:

[0044] Step 1: Preparation of graphene fiber dispersion:

[0045] Step 1.1: preparing graphene oxide powder;

[0046] Step 1.2: heating and reducing the graphene oxide powder to obtain graphene powder;

[0047] Step 1.3: preparing graphene powder into graphene fibers;

[0048] Step 1.4: Disperse the graphene fiber and metal rice noodle powder in the preparation solution;

[0049] Step 2: Prepare graphene fabric:

[0050] Step 2.1: Cut out the woven fabric and attach it to the substrate of the coater;

[0051] Step 2.2: Pour the graphene fiber dispersion into the stack head of the coating machine;

[0052] Step 2.3: Adjust the process parameters of the coating machine;

[0053] Step 2.4: Apply the graphene fiber dispersion evenly on the surface of the fabric;

[0054] Step 2.5: drying to obta...

Embodiment 1

[0081] Weigh 1 g of graphene fiber powder and 1 g of silver nanowire powder and redisperse them in 500 mL of deionized water containing 10 mg / mL CTAB and 2 mg / mL epoxy resin to prepare a graphene dispersion for use. Cut a woven or knitted fabric with a size of 25×25cm and a thickness of 1mm and attach it to the substrate of the coater, pour 100mL of the above dispersion into the pusher of the coater, and adjust the speed of the coater to 5cm / s. Complete the uniform coating of the graphene fiber and silver nanowire mixture, and dry at 60°C for 2 hours to obtain the graphene fiber fabric. After the surface is coated with a PU and PDMS waterproof coating with a thickness of 10 μm, a fast electric heating graphene fiber fabric is made after externally connecting wires, a voltage regulator, and a power supply.

Embodiment 2

[0083] Weigh 2 g of graphene fiber powder and 1 g of copper nanowire powder and redisperse them in 500 mL of deionized water containing 20 mg / mL CTAB and 3 mg / mL epoxy resin to prepare a graphene fiber dispersion for use. Cut a woven or knitted fabric with a thickness of 2mm and a size of 25×25cm and attach it to the substrate of the coater, pour 200mL of the above dispersion into the pusher of the coater, and adjust the speed of the coater to 6cm / s. Complete the uniform coating of the graphene fiber and copper nanowire mixture, and dry at 50°C for 3 hours to obtain the graphene fiber fabric. After the surface is coated with a PU and PDMS waterproof coating with a thickness of 10 μm, a fast electric heating graphene fiber fabric is made after externally connecting wires, a voltage regulator, and a power supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com