Naked perspiration fabric, preparation method and naked pajamas

A naked feeling and fabric technology, applied in the field of clothing fabrics, to achieve the effects of excellent application performance and hand feeling performance, inhibition of reproduction and growth, and improvement of softness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

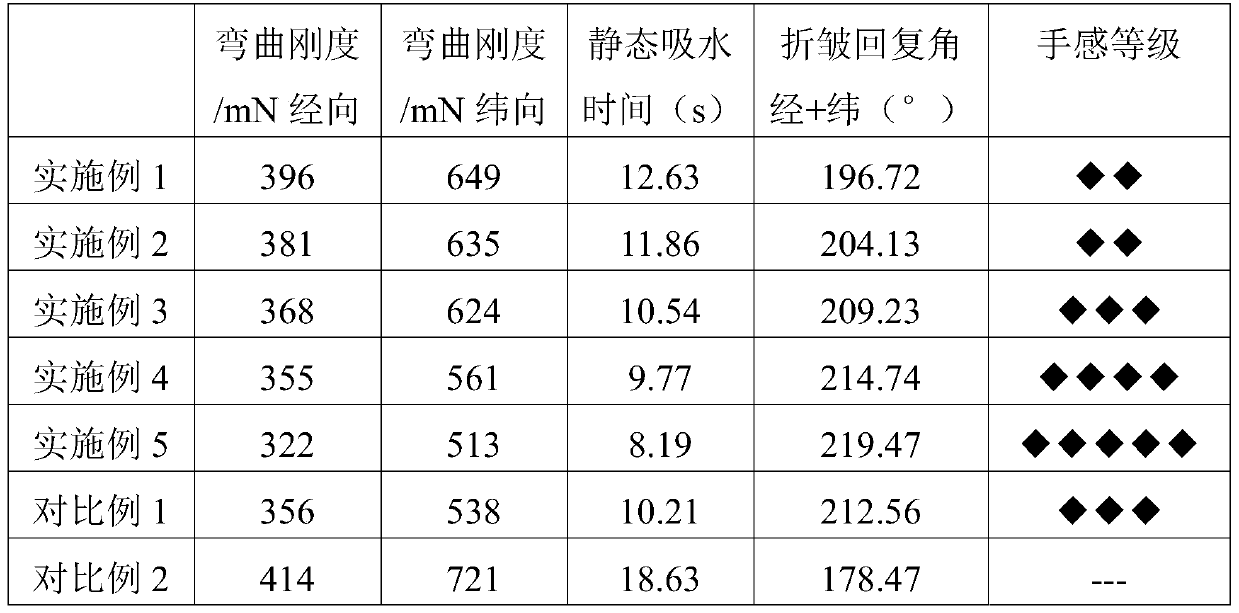

Examples

Embodiment 1

[0054] The preparation method of naked feeling sweat-wicking fabric comprises the following steps:

[0055] S1 Under constant temperature conditions of 40°C, mix the composite emulsifier and sucrose polyester at a weight ratio of 1:10 to obtain an oil phase; 2:1 mixture; under the condition of stirring at 300 rpm, add deionized water twice the weight of the oil phase to the oil phase, stir and emulsify at 2000 rpm at 40°C for 80 minutes, and let it stand for defoaming. Obtain sucrose polyester emulsion;

[0056] S2: Add 40 parts by weight of sucrose polyester emulsion, 10 parts by weight of dodecyl dimethyl betaine, 5 parts by weight of polyether polysiloxane quaternary ammonium salt, and 2 parts by weight of antioxidant into 130 parts by weight of deionized water, Mix evenly to get the naked feeling perspiration finishing liquid;

[0057] S3: Immerse the fabric in the nude feeling perspiration finishing solution at a temperature of 30°C for 30 minutes at a weight ratio of 1...

Embodiment 2

[0062] The preparation method of naked feeling sweat-wicking fabric comprises the following steps:

[0063] S1 Under constant temperature conditions of 40°C, mix the compound emulsifier, glycerin and sucrose polyester at a weight ratio of 1:15:10 to obtain an oil phase; the compound emulsifier is isomerized tridecanol polyoxyethylene ether and Span 80 A mixture composed of a weight ratio of 2:1; under the condition of stirring at 300 rpm, add deionized water twice the weight of the oil phase to the oil phase, stir and emulsify at 2000 rpm at 40°C for 80 minutes, and statically Put defoaming, obtain sucrose polyester emulsion;

[0064] S2: Add 40 parts by weight of sucrose polyester emulsion, 10 parts by weight of dodecyl dimethyl betaine, 5 parts by weight of polyether polysiloxane quaternary ammonium salt, and 2 parts by weight of antioxidant into 130 parts by weight of deionized water, Mix evenly to get the naked feeling perspiration finishing liquid;

[0065] S3: Immerse ...

Embodiment 3

[0070] The preparation method of naked feeling sweat-wicking fabric comprises the following steps:

[0071] S1 Under constant temperature conditions of 40°C, mix the compound emulsifier, glycerin and sucrose polyester at a weight ratio of 1:15:10 to obtain an oil phase; the compound emulsifier is isomerized tridecanol polyoxyethylene ether and Span 80 A mixture composed of a weight ratio of 2:1; under the condition of stirring at 300 rpm, add deionized water twice the weight of the oil phase to the oil phase, stir and emulsify at 2000 rpm at 40°C for 80 minutes, and statically Put defoaming, obtain sucrose polyester emulsion;

[0072] S2: Add 40 parts by weight of sucrose polyester emulsion, 10 parts by weight of dodecyl hydroxypropyl phosphate betaine, 5 parts by weight of polyether polysiloxane quaternary ammonium salt, and 2 parts by weight of antioxidant to 130 parts by weight of deionized In water, mix evenly to get naked feeling perspiration finishing liquid;

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com