Photoelectric detector and preparation method thereof

A technology of photodetectors and gratings, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as increasing production costs, and achieve the effects of reducing production costs, enhancing feasibility, and simplifying production

- Summary

- Abstract

- Description

- Claims

- Application Information

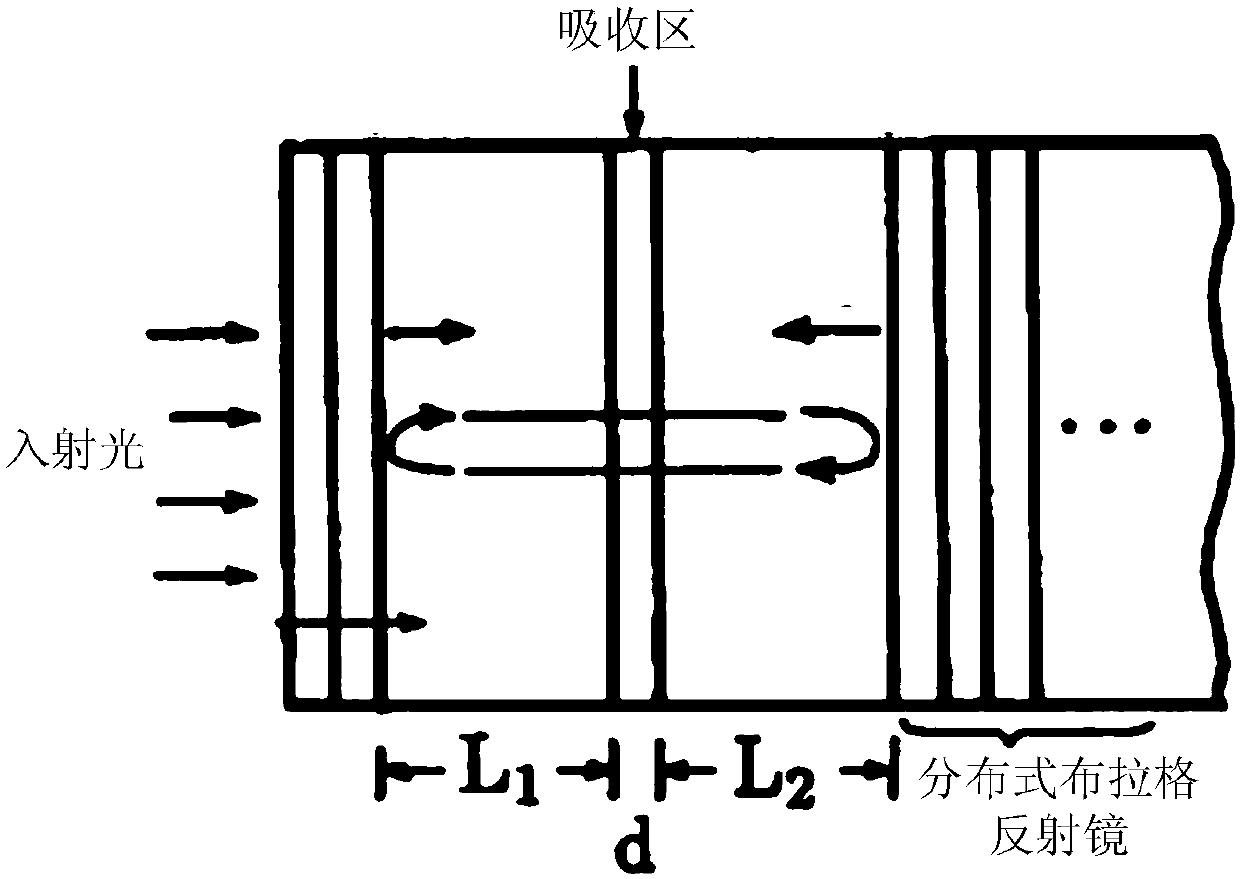

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1, making a lower contact electrode on the lower contact layer;

[0059] Using metal-organic chemical vapor deposition (metal-organic chemical vapor deposition, MOCVD) technology or molecular beam epitaxy (MBE) technology, the buffer layer, lower contact layer, transition layer and absorption layer are epitaxially on the N-type substrate. Floor. If the remaining area is etched down to the lower contact layer, a lower contact electrode can be formed on the lower contact layer by a photolithography process.

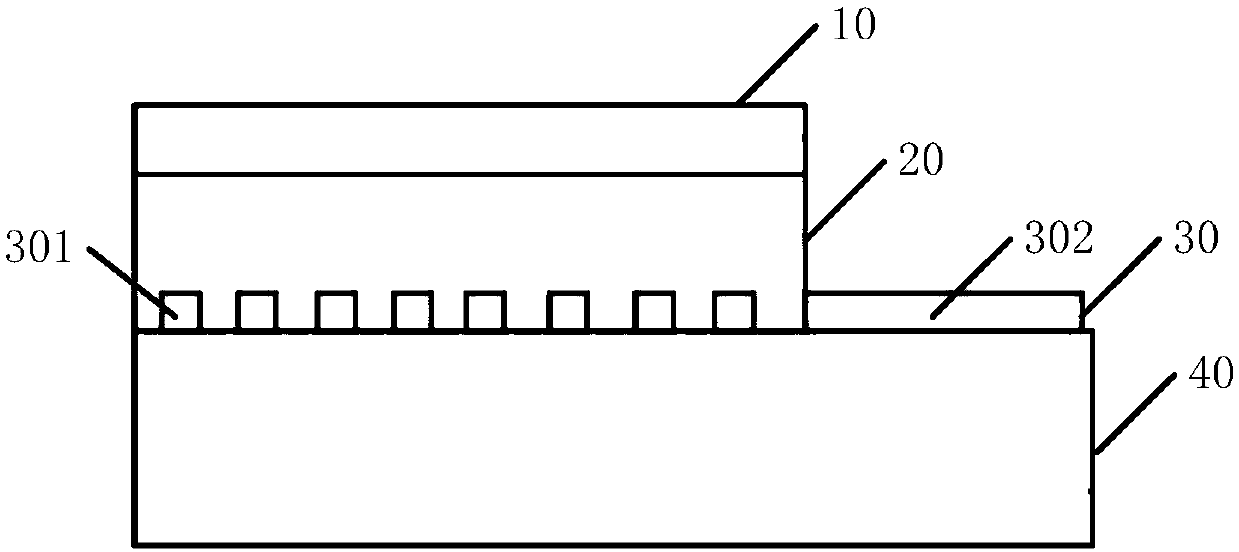

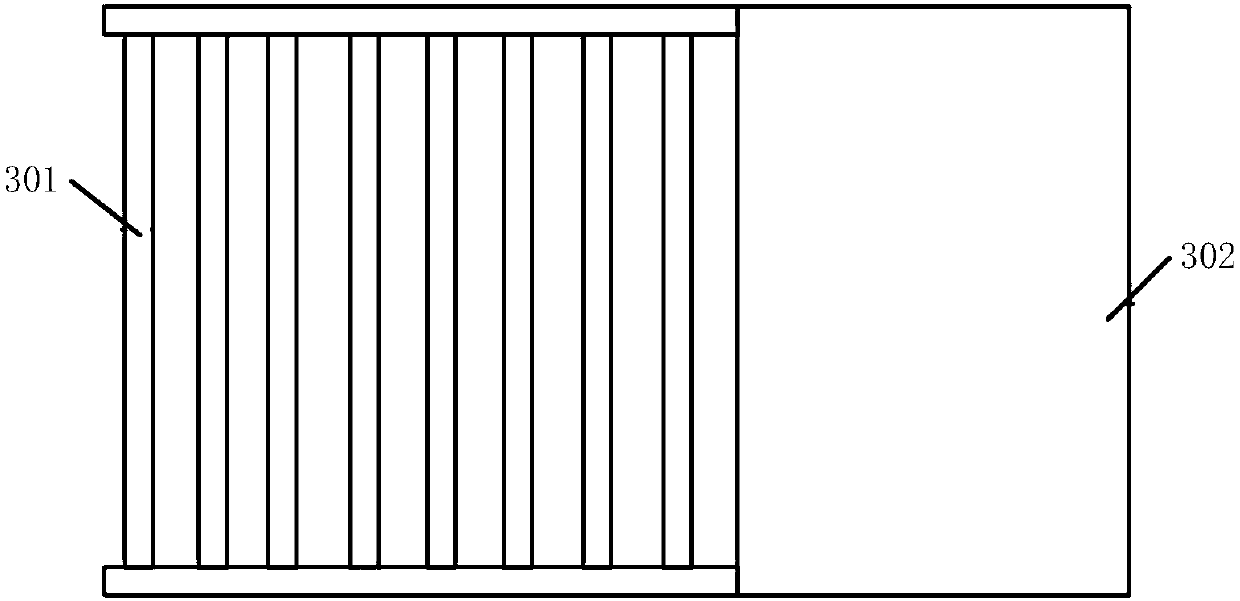

[0060] see figure 2 , figure 2 It is a schematic diagram of an embodiment of the photodetector in the embodiment of the present application, the photodetector includes an absorption layer 40, a metal layer 30, a dielectric film 20 and a reflective metal 10 arranged in sequence from the bottom layer to the top layer;

[0061] The absorbing layer 40 is used to absorb target detection light;

[0062] The metal layer 30 includes a strip grating 301 and a...

Embodiment 2

[0076] Embodiment 2, making the lower contact electrode on the N-type substrate;

[0077] Using MOCVD technology or MBE technology, the buffer layer, the transition layer and the absorption layer are extended sequentially on the N-type substrate. If the remaining area is etched to the N-type substrate, the lower contact electrode can be fabricated on the N-type substrate by photolithography.

[0078] see again figure 2 , figure 2 It is a schematic diagram of an embodiment of the photodetector in the embodiment of the present application, the photodetector includes an absorption layer 40, a metal layer 30, a dielectric film 20 and a reflective metal 10 arranged in sequence from the bottom layer to the top layer;

[0079] The absorbing layer 40 is used to absorb target detection light;

[0080] The metal layer 30 includes a strip grating 301 and an upper contact electrode 302. One side of the strip grating 301 is located on the absorbing layer 40. The strip grating 301 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com