Flexible vanadium tetrasulfide-carbon composite anode material and preparation method and application thereof

A technology of vanadium tetrasulfide and positive electrode materials, applied in the direction of positive electrodes, active material electrodes, battery electrodes, etc., can solve problems such as poor conductivity and insufficient capacity, and achieve increased capacity, improved electronic conductivity, and enhanced electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of composite material: 20% of sulfur powder and 80% of vanadyl acetylacetonate powder by mass percentage, according to the ratio of solid powder: N-N dimethylformamide (DMF) solution=1g:10mL, add DMF solution, in Stir and mix evenly at 65°C, control the stirring rate to 600r / min, and stir for 12h to ensure that the solid powder is evenly mixed in the DMF solution; pour the obtained mixed solution into a high-temperature and high-pressure reactor, and pour it into Add a piece of carbon fiber cloth of 2cm×2cm, then place the reaction kettle in an oven, react at 140°C for 2h, and rinse it with ethanol for 3 times.

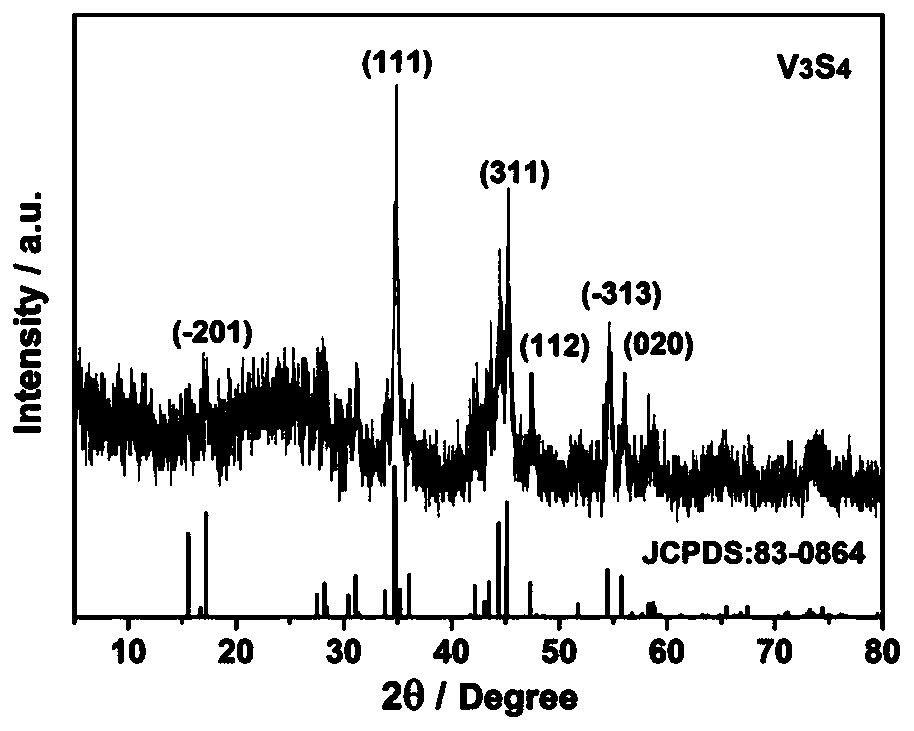

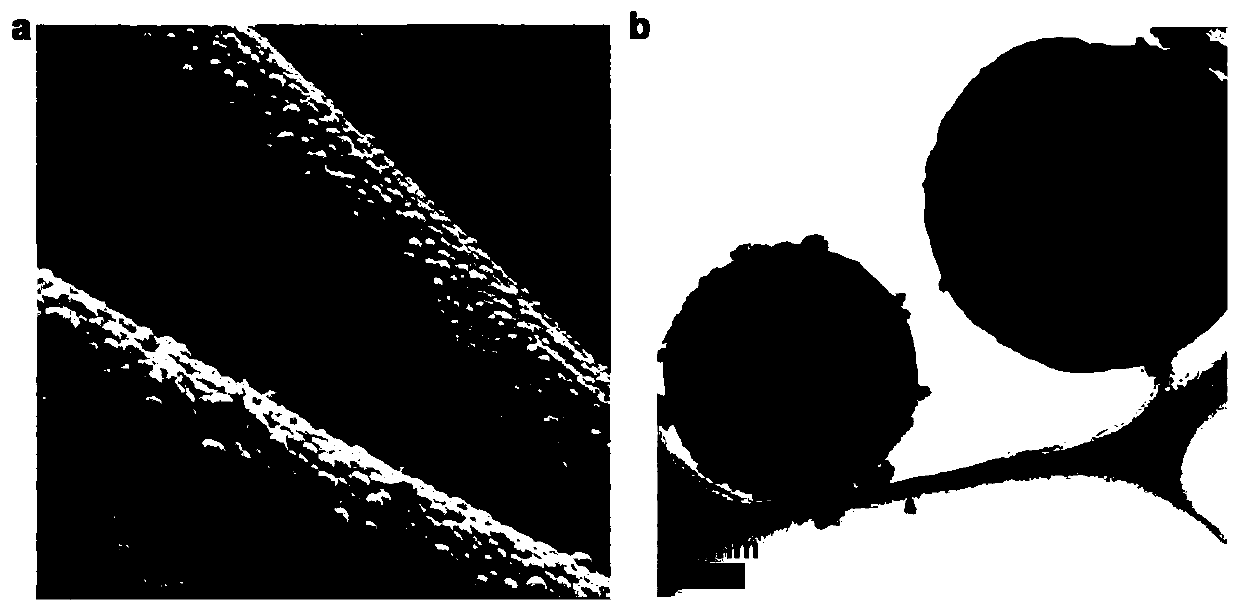

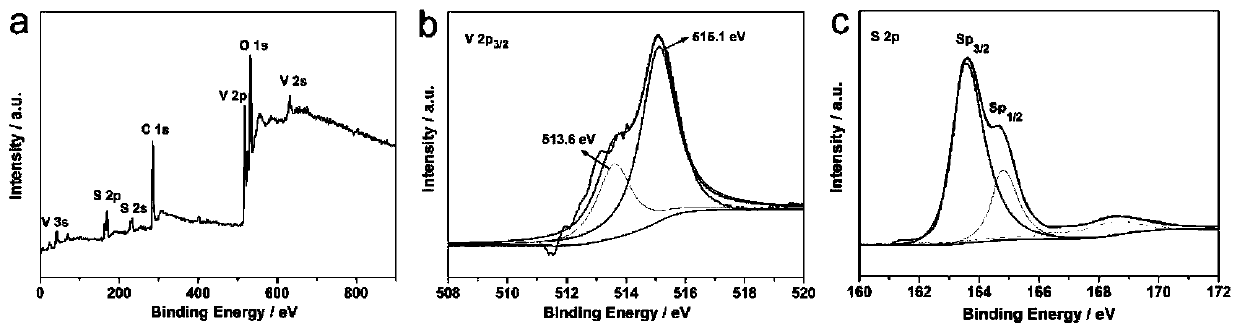

[0046] (2) Preparation of flexible battery composite positive electrode material: take the composite material obtained in (1) in a tube furnace, and calcinate it for 2 hours at 400° C. under a nitrogen atmosphere to obtain a flexible battery composite positive electrode material. Its XRD diagram is shown in figure 1 , SEM and TEM pictures see ...

Embodiment 2

[0050] (1) Preparation of composite material: 30% of sulfur powder and 70% of vanadyl acetylacetonate powder by mass percentage, according to the ratio of solid powder: N-N dimethylformamide (DMF) solution=1g:20mL, add DMF solution, in Stir and mix evenly at 70°C, control the stirring rate to 600r / min, and stir for 24 hours to ensure that the solid powder is evenly mixed in the DMF solution; pour the obtained mixed solution into a high-temperature and high-pressure reactor, and add A piece of commercial carbon fiber cloth of 2cm×2cm was used, and then the reactor was placed in an oven, reacted at 160°C for 3 hours, and then rinsed with ethanol for 3 times.

[0051] (2) Preparation of flexible battery composite positive electrode material: take the composite material obtained in (1) in a tube furnace, and calcinate it for 2 hours at 500° C. under a nitrogen atmosphere to obtain a flexible battery composite positive electrode material.

[0052] (3) Assembly of flexible battery: ...

Embodiment 3

[0055] (1) Preparation of composite material: 40% of sulfur powder and 60% of vanadyl acetylacetonate powder by mass percentage, according to the ratio of solid powder: N-N dimethylformamide (DMF) solution=1g:30mL, add DMF solution, in Stir and mix evenly at 80°C, control the stirring rate to 600r / min, and stir for 24 hours to ensure that the solid powder is evenly mixed in the DMF solution; pour the obtained mixed solution into a high-temperature and high-pressure reactor, and add A piece of commercial carbon fiber cloth of 2cm×2cm was used, and then the reactor was placed in an oven, reacted at 180°C for 4 hours, and rinsed with ethanol for 3 times.

[0056] (2) Preparation of flexible battery composite positive electrode material: take the composite material obtained in (1) in a tube furnace, and calcinate it for 4 hours at 700° C. under a nitrogen atmosphere to obtain a flexible battery composite positive electrode material.

[0057] (3) Assembly of flexible battery: The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com