Degumming agent for removing back gum on glass rear cover of mobile phone, degumming method for glass rear cover of mobile phone, and glass rear cover of mobile phone

A degumming agent, glass technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of impermeability, environmental protection, poor degumming effect, etc., to achieve enhanced penetration effect, safety Environmental protection cost, good degumming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

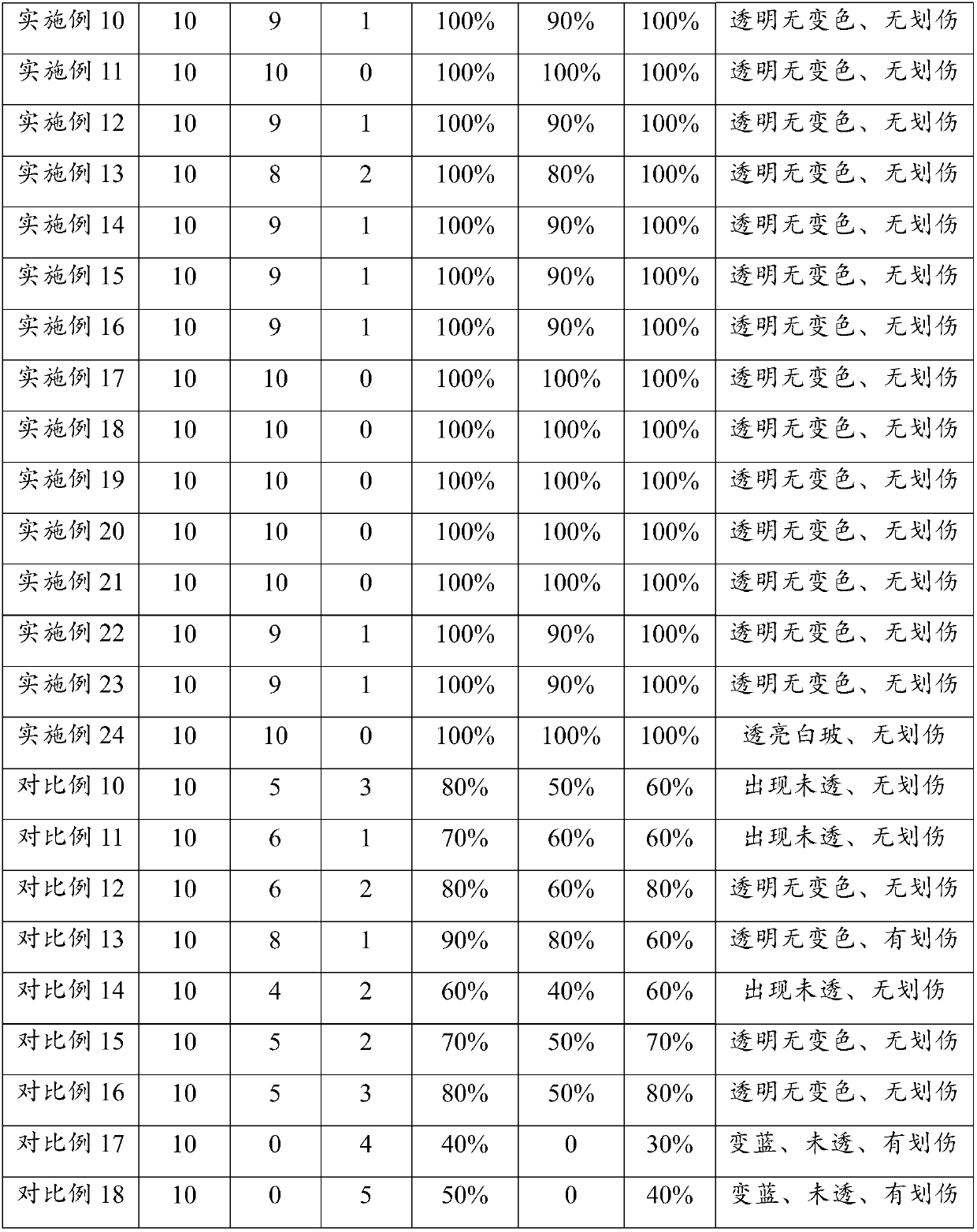

Examples

Embodiment 1

[0103] A degumming agent for removing the adhesive on the back cover of mobile phone glass, which consists of the following components in mass percentage: 65% of ethanol, 20% of dipropylene glycol monomethyl ether, 5% of triphenyl phosphate and 10% of ethylene glycol %.

Embodiment 2

[0105] A degumming agent for removing the adhesive on the back cover of mobile phone glass, which consists of the following components in mass percentage: 80% ethanol, 10% dipropylene glycol monomethyl ether, 3% tricresyl phosphate and 1,2- Propylene Glycol 7%.

Embodiment 3

[0107] A degumming agent for removing the adhesive on the back cover of mobile phone glass, consisting of the following components in mass percentage: 73% ethanol, 15% dipropylene glycol monomethyl ether, 5% tributyl phosphate and 7% ethylene glycol %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com