Preparation method of pharmaceutical terbutaline sulfate crystal form B

A technology of terbutaline sulfate and crystal form, which is applied in the field of medicine, can solve the problems of not meeting pharmaceutical standards, being unstable, and difficult to control the mixing ratio, and achieves safe and simple preparation process and purification steps, mild reaction conditions, and high product quality. high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

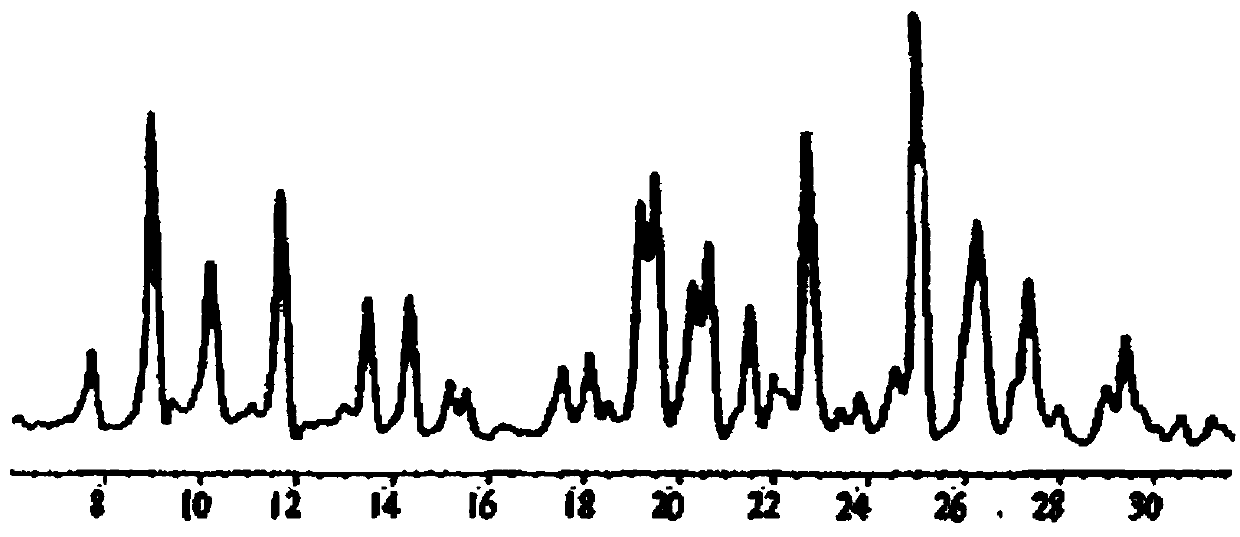

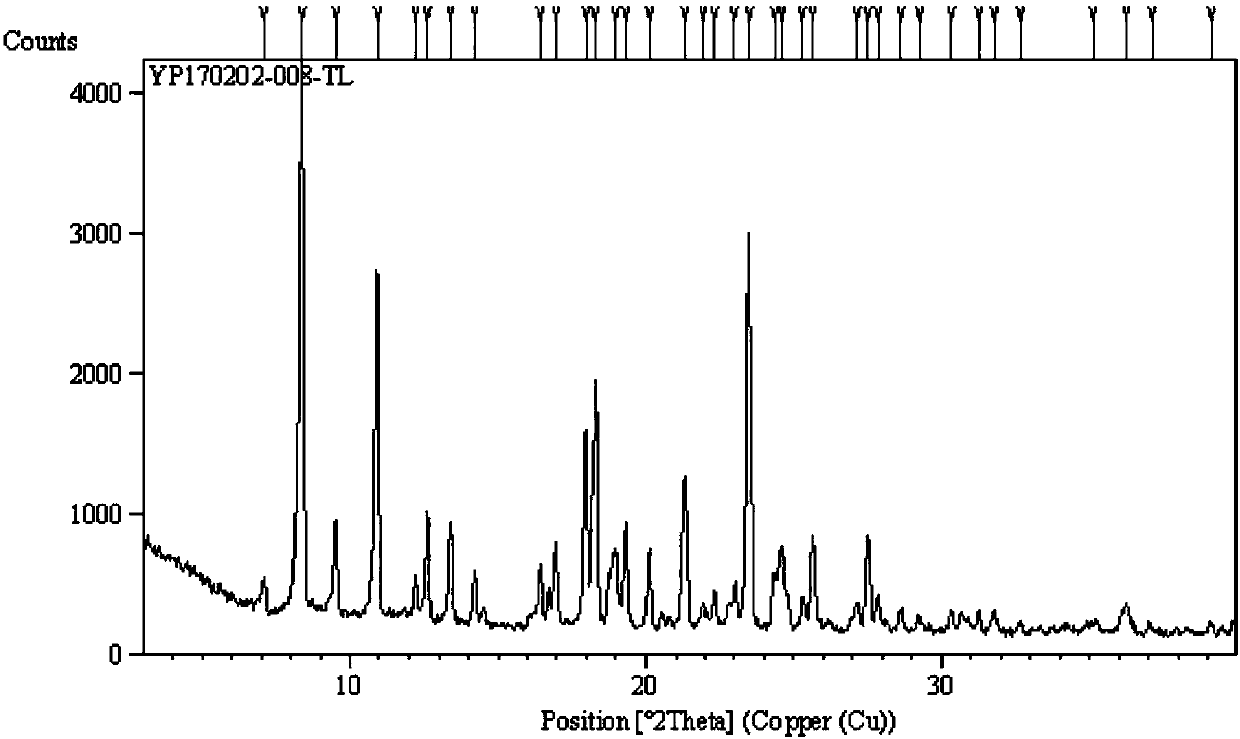

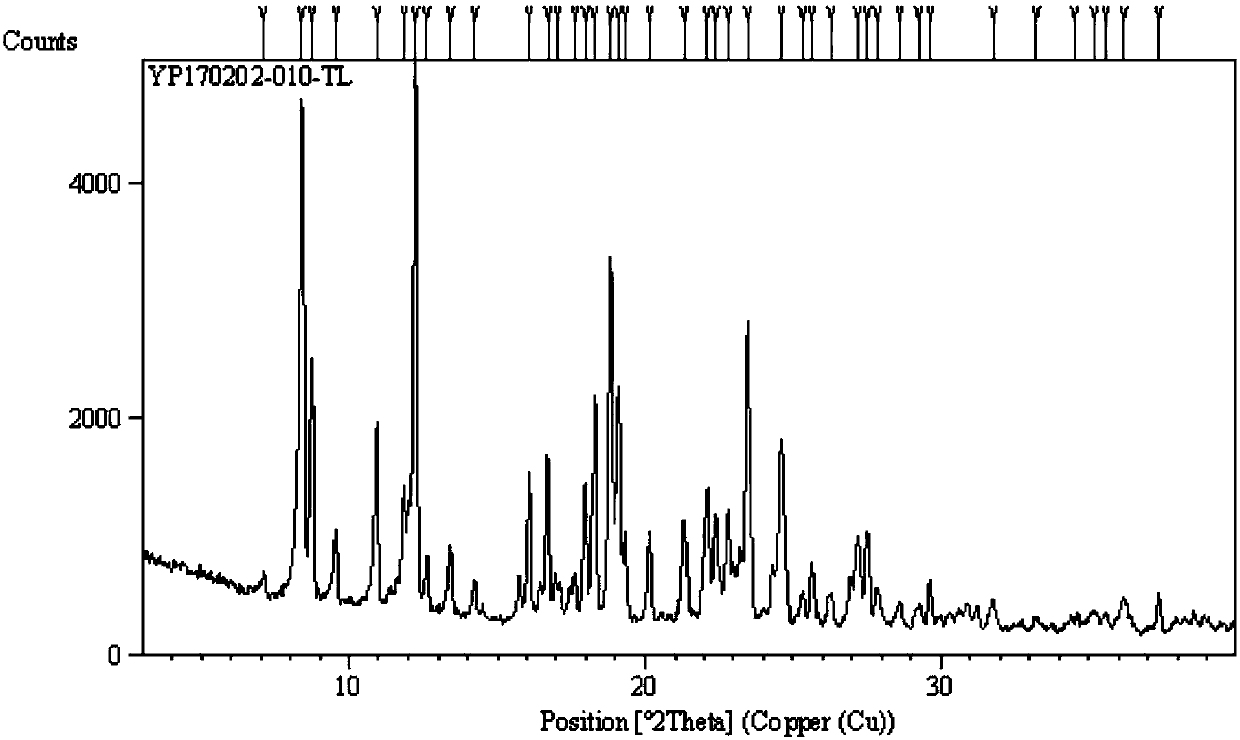

Image

Examples

Embodiment 1

[0027] S1. Dissolve 5 g of Terbutaline Sulfate of Amorphous Form B in 20 mL of pure water, stir and dissolve at 20° C. to obtain an aqueous solution of Terbutaline Sulfate;

[0028] S2. Add the terbutaline sulfate aqueous solution obtained in step S1 dropwise into 300 mL of absolute ethanol, stir to dissolve, add the seed crystal of terbutaline sulfate crystal form B, stir and crystallize at 10°C for 48 hours, and obtain a white suspension Liquid, i.e. the terbutaline sulfate crystallization liquid of crystal form B;

[0029] S3. Filter the white suspension obtained in step S2, wash the filter cake with absolute ethanol, and dry under normal pressure to obtain 2.8 g of terbutaline sulfate crystal form B as a white solid, with a water content of less than 0.5%.

Embodiment 2

[0031] S1. Dissolve 5 g of Terbutaline Sulfate of Amorphous Form B in 25 mL of pure water, stir and dissolve at 30° C. to obtain an aqueous solution of Terbutaline Sulfate;

[0032] S2. Add the terbutaline sulfate aqueous solution obtained in step S1 dropwise into 200 mL of acetone, stir to dissolve, add the seed crystal of terbutaline sulfate crystal form B, stir and crystallize at 15° C. for 36 hours to obtain a white suspension, That is, the terbutaline sulfate crystallization solution of crystal form B;

[0033] S3. Filter the white suspension obtained in step S2, wash the filter cake with acetone, and dry under normal pressure to obtain 3.5 g of terbutaline sulfate crystal form B as a white solid with a water content of less than 0.5%.

Embodiment 3

[0035] S1. Dissolve 5 g of Terbutaline Sulfate of Amorphous Form B in 25 mL of pure water, stir and dissolve at 30° C. to obtain an aqueous solution of Terbutaline Sulfate;

[0036] S2. Add the aqueous solution of terbutaline sulfate obtained in step S1 dropwise into 200 mL of butanone, stir to dissolve, add the seed crystal of terbutaline sulfate crystal form B, stir and crystallize at 15°C for 38 hours to obtain a white suspension , namely the terbutaline sulfate crystallization liquid of crystal form B;

[0037] S3. Filter the white suspension obtained in step S2, wash the filter cake with methyl ethyl ketone, and dry under normal pressure to obtain 3.1 g of terbutaline sulfate crystal form B as a white solid, with a water content of less than 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com