Photoacoustic signal detection and imaging method based on micro-nano motor

A micro-nano motor, photoacoustic signal technology, applied in measurement devices, diagnostic recording/measurement, material analysis by optical means, etc., can solve the problems of low motor driving speed and complex preparation process, and achieve breakthroughs in technical bottlenecks and simplification. The effect of the drive guide mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

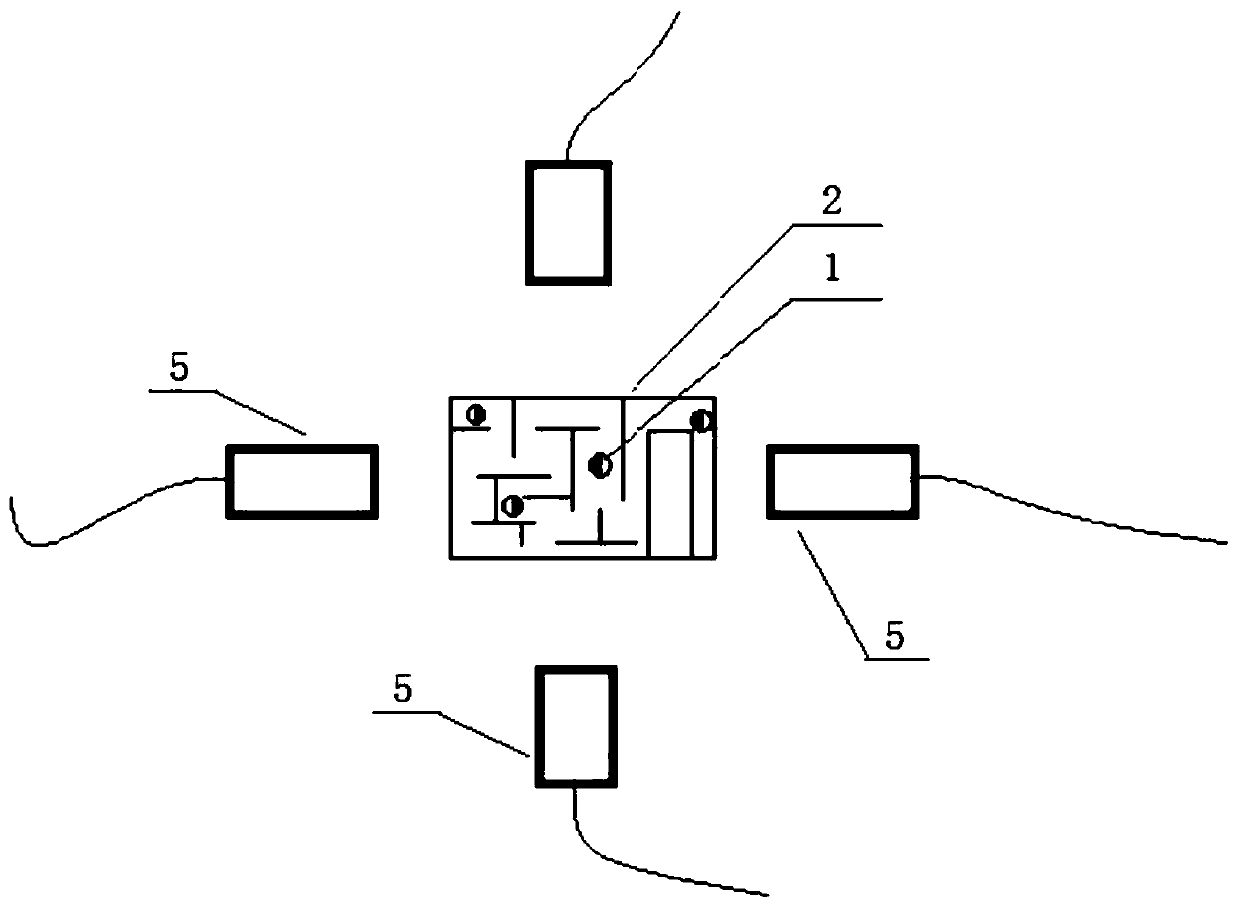

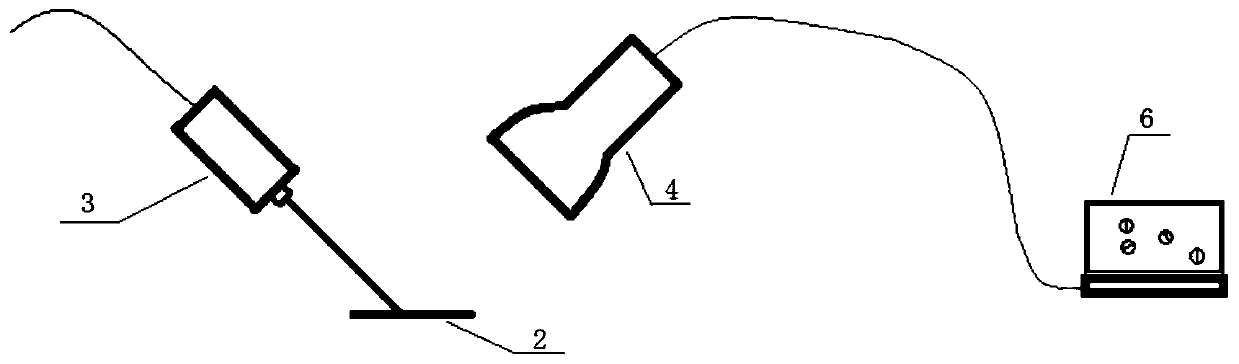

[0030] Such as Figure 1-4 As shown, the micro-nano motor-based photoacoustic signal detection and imaging method, the micro-nano motor-based photoacoustic signal detection and imaging method includes:

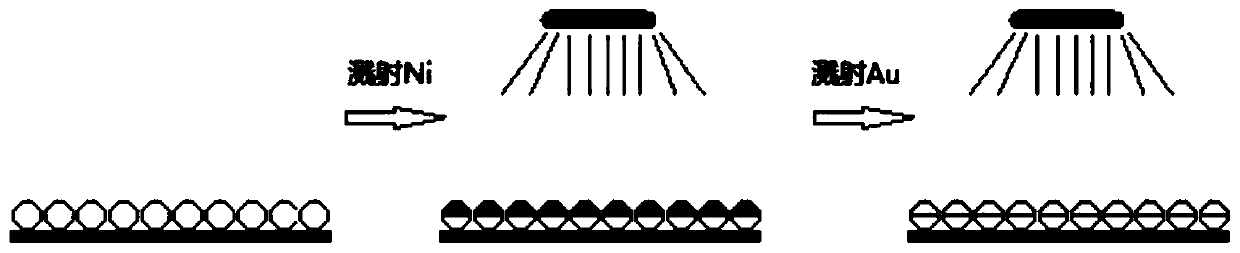

[0031] S1: A detection and imaging system to be used for photoacoustic signal detection and imaging based on micro-nano motors. The system includes sputtering ferromagnetic metal layer 1-1 and photothermal conversion metal layer 1-2 sequentially on one hemispherical surface Micro-nano motor 1 composed of base spheres 1-3, container containing deionized water 2, nanosecond pulse near-infrared laser light source 3, ultrasonic detector 4, power amplifier, filter, electromagnetic coil 5, and images equipped with imaging algorithm software The computer 6 is reconstructed; the micro-nano motor 1 is located in the container 2; the output end of the ultrasonic detector 4 is electrically connected to the input end of the power amplifier; the output end of the power amplifier is electri...

specific Embodiment approach 2

[0037] Such as Figure 1-4 As shown, the container 2 is one of a clean Petri dish, a capillary or a microchannel on a PDMS substrate.

specific Embodiment approach 3

[0039] Such as Figure 1-4 As shown, the wavelength range of the nanosecond pulsed near-infrared laser light source 3 is 780nm-808nm, and the pulse width is 10-15 nanoseconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com