Degradable, environment-friendly and antifouling microcapsules as well as preparation method and application thereof

A microcapsule and antifouling technology, applied in the directions of microcapsule preparation, microsphere preparation and application, can solve the problems of inability to provide protection effect for a long time, inability to achieve long-term effect, injury to construction personnel, etc., and achieve sustained and stable slow release. effect, excellent encapsulation performance, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

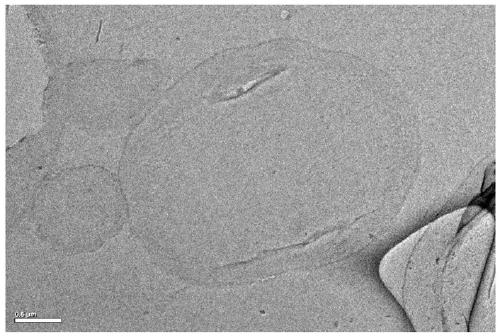

[0039] A preparation process of degradable environment-friendly and antifouling microcapsules: dissolve 5g of chitosan (degree of deacetylation ≥70%) with 1g of hydrochloric acid, add 200g of water, add 5g of capsaicin and fully stir to form a stable suspension with viscosity , and then squeeze the suspension into small droplets (the injection rate of the syringe pump is 0.05mL / min, and the air flow rate is 1mL / min) through the electric uniform speed syringe pump, and then drop into the CaCl 2(mass percentage 1%) in a salt water bath, after 0.5h of solidification, the degradable environment-friendly antifouling microcapsules are obtained.

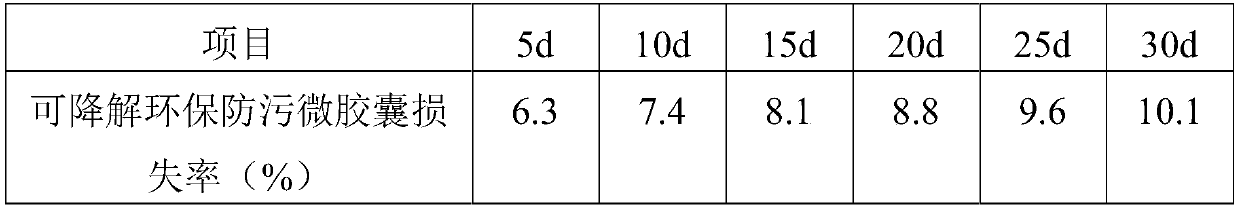

[0040] Take 5g of degradable environmental protection and antifouling microcapsules, put them in a 50mL open conical flask, put them in a constant temperature oven at 50°C, take samples in real time to measure the quality of the samples, and compare the sustained release performance of the microcapsules by measuring the loss rate of the samp...

Embodiment 2

[0046] A kind of preparation process of degradable environment-friendly antifouling microcapsules: dissolving 5g chitosan (deacetylation degree ≥ 70%) with 1g acetic acid, and adding 200g water, adding 5g dihydrocapsaicin and fully stirring to form a viscous Stabilize the suspension, and then squeeze the suspension into small droplets through an electric constant-speed syringe pump (the injection rate of the syringe pump is 0.05mL / min; the gas shear rate is 1mL / min), and drop it into the CaCl 2 (mass percentage 1%) in a salt water bath, after 0.5h of solidification, the degradable environment-friendly antifouling microcapsules are obtained.

[0047] Take 5g of degradable environmental protection and antifouling microcapsules, put them in a 50mL open conical flask, put them in a constant temperature oven at 50°C, take samples in real time to measure the quality of the samples, and compare the sustained release performance of the microcapsules by measuring the loss rate of the sa...

Embodiment 3

[0053] A preparation process of degradable environmental protection and antifouling microcapsules: dissolve 5g chitosan with 1g hydrochloric acid and add 200g water, add 5g nordihydrocapsaicin and stir well to form a stable suspension with viscosity Syringe pump, squeeze the suspension into small droplets (the injection rate of the syringe pump is 0.05mL / min, the flow rate of the air is 1mL / min), drop into the CaCl 2 (mass percentage 1%) in a salt water bath, after 0.5h of solidification, the degradable environment-friendly antifouling microcapsules are obtained.

[0054] Take 5g of degradable environmental protection and antifouling microcapsules, put them in a 50mL open conical flask, put them in a constant temperature oven at 50°C, take samples in real time to measure the quality of the samples, and compare the sustained release performance of the microcapsules by measuring the loss rate of the sample quality. The results are shown in Table 3 below.

[0055] The microcapsu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com