Preparation method of beta-FeOOH/g-C3N4 heterojunction photocatalytic material

A photocatalytic material, g-c3n4 technology, applied in the field of preparation of β-FeOOH/g-C3N4 heterojunction photocatalytic materials, can solve the problems of affecting the rate of hydrogen production by photolysis, the inability of electrons to be transferred quickly, etc. The method is simple and mature, the cost is low, and the catalytic efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

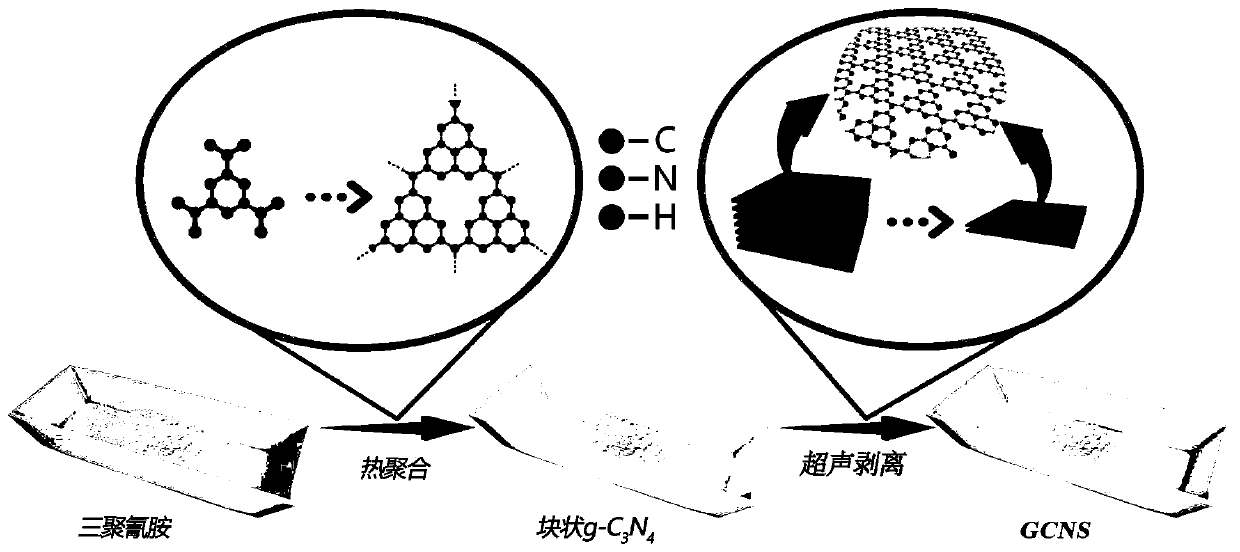

[0036] Lumpy g-C 3 N 4 The preparation method:

[0037] Spread the melamine reagent in a ceramic crucible, put it into a muffle furnace and cover it. The heating rate is 5°C / min, and the final temperature is 520°C. After 5 hours of heat preservation, it is cooled to room temperature with the furnace. All the other conditions remained unchanged, and the heat preservation time was changed to 3 hours for thermal polymerization again. The final heating rate is 5°C / min, the final temperature is 550°C, heat preservation for 3 hours and then heat polymerization once, and finally obtain the light yellow product block g-C 3 N 4 .

Embodiment 2

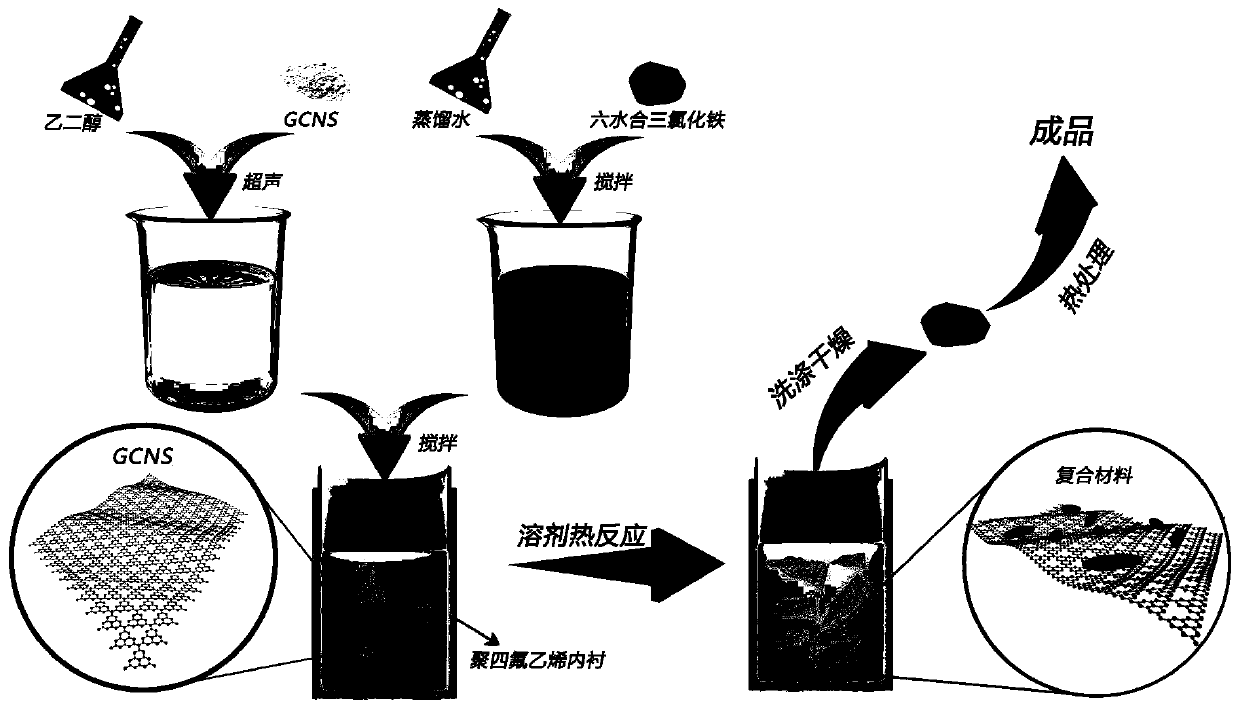

[0039] A β-FeOOH / g-C 3 N 4 A method for preparing a heterojunction photocatalytic material, comprising the steps of:

[0040] (1) Spread the melamine reagent in a ceramic crucible, put it into a muffle furnace and cover it. The heating rate is 5°C / min, and the final temperature is 520°C. After 5 hours of heat preservation, it is cooled to room temperature with the furnace. All the other conditions remained unchanged, and the heat preservation time was changed to 3 hours for thermal polymerization again. The final heating rate is 5°C / min, the final temperature is 550°C, heat preservation for 3 hours and then heat polymerization once, and finally obtain the light yellow product block g-C 3 N 4 ;

[0041] (2) Take 2mol of FeCl 3 ·6H 2 O was dissolved in 15ml of deionized water to obtain FeCl 3 solution, take block g-C 3 N 4 The mass of FeCl 3 ·6H 2 1 / 20 of O, and disperse it in 5ml of ethylene glycol, and ultrasonic 30min, to obtain the GCNS suspension of ultrasonic-as...

Embodiment 3

[0044] One-dimensional FeOOH and two-dimensional g-C 3 N 4 The preparation method of the composite material:

[0045] (1) Spread the melamine reagent in a ceramic crucible, put it into a muffle furnace and cover it. The heating rate is 5°C / min, and the final temperature is 520°C. After 5 hours of heat preservation, it is cooled to room temperature with the furnace. All the other conditions remained unchanged, and the heat preservation time was changed to 3 hours for thermal polymerization again. The final heating rate is 5°C / min, the final temperature is 550°C, heat preservation for 3 hours and then heat polymerization once, and finally obtain the light yellow product block g-C 3 N 4 ;

[0046] (2) Take 1mol of FeCl 3 ·6H 2 Dissolve O in 15ml of deionized water, take block g-C 3 N 4 The mass of FeCl 3 ·6H 2 1 / 20 of O was dispersed in 5ml of ethylene glycol, and ultrasonicated for 30min to obtain GCNS suspension, FeCl 3 The solution was added to the GCNS suspension, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com