High-strength high-permeability concrete and preparation method thereof

A high-strength, concrete technology, applied in the field of concrete, can solve the problems of low compressive strength and flexural strength, and achieve the effects of improving water permeability, improving cohesion, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

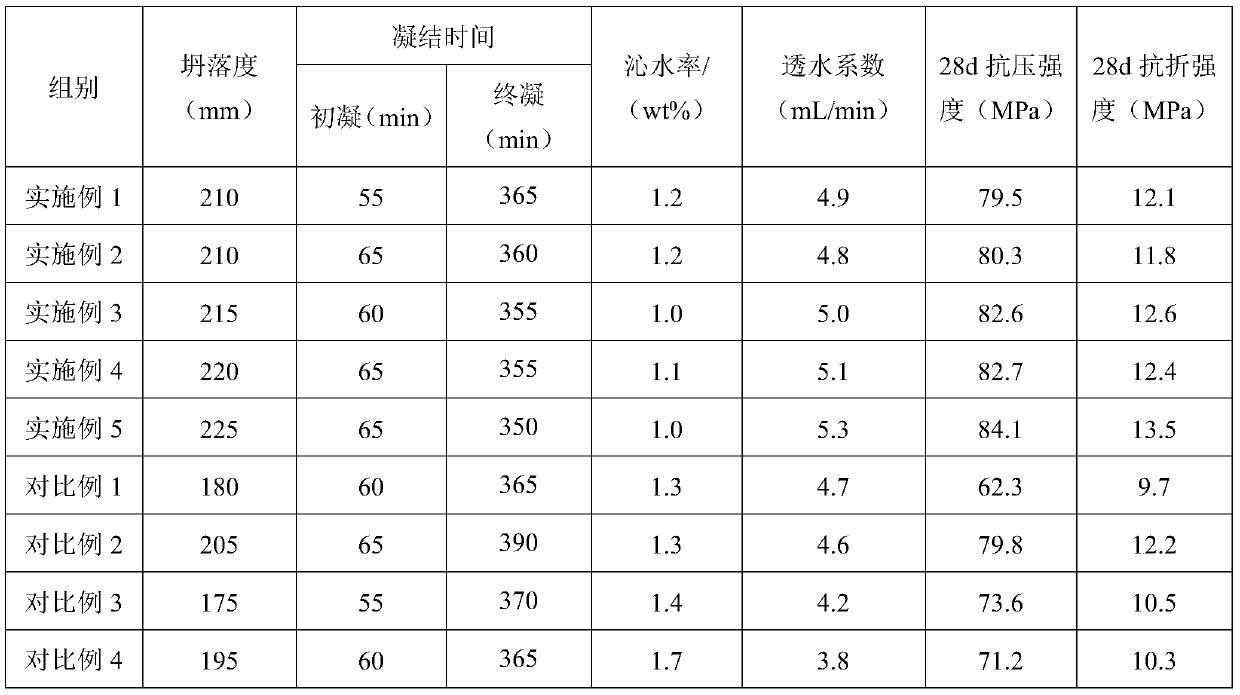

Examples

Embodiment 1

[0032] A high-strength and high-permeability concrete, consisting of the following components by weight:

[0033] 5 parts of water, 15 parts of cement, 50 parts of quartz sand, 1 part of tetrabutyl titanate, 0.3 parts of boron fiber, 0.5 parts of molybdenum disulfide, 1 part of lithium-based bentonite, 0.06 parts of polycarboxylate superplasticizer, carbon black 0.05 parts, 0.4 parts of rosin, 0.3 parts of early strength agent, 1 part of air-entraining agent, 1.5 parts of ethyl orthosilicate,

[0034] Among them, the early strength agent is a mixture of dodecyl glucoside, aminopropyltriethoxysilane, and lithium sulfate with a mass ratio of 1:2:1.5, the particle size of the quartz sand is 1-2mm, and the diameter of the boron fiber is 0.14mm, the air-entraining agent is a mixture of polyacrylic acid and sodium dodecylbenzenesulfonate with a mass ratio of 2:1,

[0035] Its preparation method comprises the following steps:

[0036] S1. According to the above formula, weigh each ...

Embodiment 2

[0043] A high-strength and high-permeability concrete, consisting of the following components by weight:

[0044] 10 parts of water, 35 parts of cement, 75 parts of quartz sand, 3 parts of tetrabutyl titanate, 1.5 parts of boron fiber, 4.5 parts of molybdenum disulfide, 5 parts of lithium bentonite, 0.15 parts of polycarboxylate superplasticizer, carbon black 0.1 parts, 0.5 parts of rosin, 0.8 parts of early strength agent, 1.5 parts of air-entraining agent, 5 parts of ethyl orthosilicate,

[0045]Among them, the early strength agent is a mixture of dodecyl glucoside, aminopropyltriethoxysilane, and lithium sulfate with a mass ratio of 1:2:1.5, the particle size of the quartz sand is 1-2mm, and the diameter of the boron fiber is 0.14mm, the air-entraining agent is a mixture of polyacrylic acid and sodium dodecylbenzenesulfonate with a mass ratio of 2:1,

[0046] Its preparation method comprises the following steps:

[0047] S1. According to the above formula, weigh each comp...

Embodiment 3

[0054] A high-strength and high-permeability concrete, consisting of the following components by weight:

[0055] 7 parts of water, 23 parts of cement, 29 parts of quartz sand, 1.5 parts of tetrabutyl titanate, 0.6 parts of boron fiber, 2 parts of molybdenum disulfide, 2 parts of lithium bentonite, 0.09 parts of polycarboxylate superplasticizer, carbon black 0.07 parts, 0.43 parts of rosin, 0.4 parts of early strength agent, 1.2 parts of air-entraining agent, 2.7 parts of ethyl orthosilicate,

[0056] Among them, the early strength agent is a mixture of dodecyl glucoside, aminopropyltriethoxysilane, and lithium sulfate with a mass ratio of 1:2:1.5, the particle size of the quartz sand is 1-2mm, and the diameter of the boron fiber is 0.14mm, the air-entraining agent is a mixture of polyacrylic acid and sodium dodecylbenzenesulfonate with a mass ratio of 2:1,

[0057] Its preparation method comprises the following steps:

[0058] S1. According to the above formula, weigh each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com