Long-acting waterborne metal heat-insulating and anti-corrosive paint

A kind of anti-corrosion coating, water-based technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problem that the anti-corrosion performance of metal surface adsorption performance cannot be further improved, and achieve the effect of improving anti-corrosion performance, improving adsorption, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

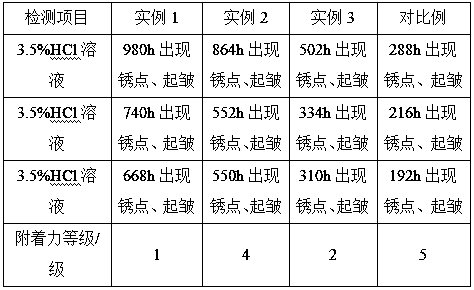

Examples

example 1

[0025] Mix sodium lignosulfonate and water in a beaker at a mass ratio of 1:25, stir and mix for 40 minutes at a temperature of 60°C and a rotational speed of 400r / min, and then use a 30% mass fraction of sodium hydroxide solution Adjust the pH of the material in the beaker to 11 to obtain a sodium lignosulfonate dispersion, mix the sodium lignosulfonate dispersion and formaldehyde in a three-necked flask at a mass ratio of 30:3, and add lignosulfonic acid into the three-necked flask Sodium sulfite with 0.05 times the mass of sodium is stirred and reacted for 4 hours at a temperature of 80°C and a rotational speed of 320r / min to obtain a prepolymer dispersion. Mix the prepolymer dispersion and potassium iodide at a mass ratio of 100:1 in Add a 1,6-dibromomethane solution that is 0.5 times the mass of the prepolymer dispersion into the four-necked flask, and stir and react for 6 hours at a temperature of 80°C and a rotational speed of 400r / min to obtain The mixture is extracted...

example 2

[0027] Mix sodium lignosulfonate and water in a beaker at a mass ratio of 1:25, stir and mix for 40 minutes at a temperature of 60°C and a rotational speed of 400r / min, and then use a 30% mass fraction of sodium hydroxide solution Adjust the pH of the material in the beaker to 11 to obtain a sodium lignosulfonate dispersion, mix the sodium lignosulfonate dispersion and formaldehyde in a three-necked flask at a mass ratio of 30:3, and add lignosulfonic acid into the three-necked flask Sodium sulfite with 0.05 times the mass of sodium is stirred and reacted for 4 hours at a temperature of 80°C and a rotational speed of 320r / min to obtain a prepolymer dispersion. Mix the prepolymer dispersion and potassium iodide at a mass ratio of 100:1 in Add a 1,6-dibromomethane solution that is 0.5 times the mass of the prepolymer dispersion into the four-necked flask, and stir and react for 6 hours at a temperature of 80°C and a rotational speed of 400r / min to obtain The mixture is extracted...

example 3

[0029] Mix sodium lignosulfonate and water in a beaker at a mass ratio of 1:25, stir and mix for 40 minutes at a temperature of 60°C and a rotational speed of 400r / min, and then use a 30% mass fraction of sodium hydroxide solution Adjust the pH of the material in the beaker to 11 to obtain a sodium lignosulfonate dispersion, mix the sodium lignosulfonate dispersion and formaldehyde in a three-necked flask at a mass ratio of 30:3, and add lignosulfonic acid into the three-necked flask Sodium sulfite with 0.05 times the mass of sodium is stirred and reacted for 4 hours at a temperature of 80°C and a rotational speed of 320r / min to obtain a prepolymer dispersion. Mix the prepolymer dispersion and potassium iodide at a mass ratio of 100:1 in Add a 1,6-dibromomethane solution that is 0.5 times the mass of the prepolymer dispersion into the four-necked flask, and stir and react for 6 hours at a temperature of 80°C and a rotational speed of 400r / min to obtain The mixture, after extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com