A modification method of biochar and its application in soil remediation

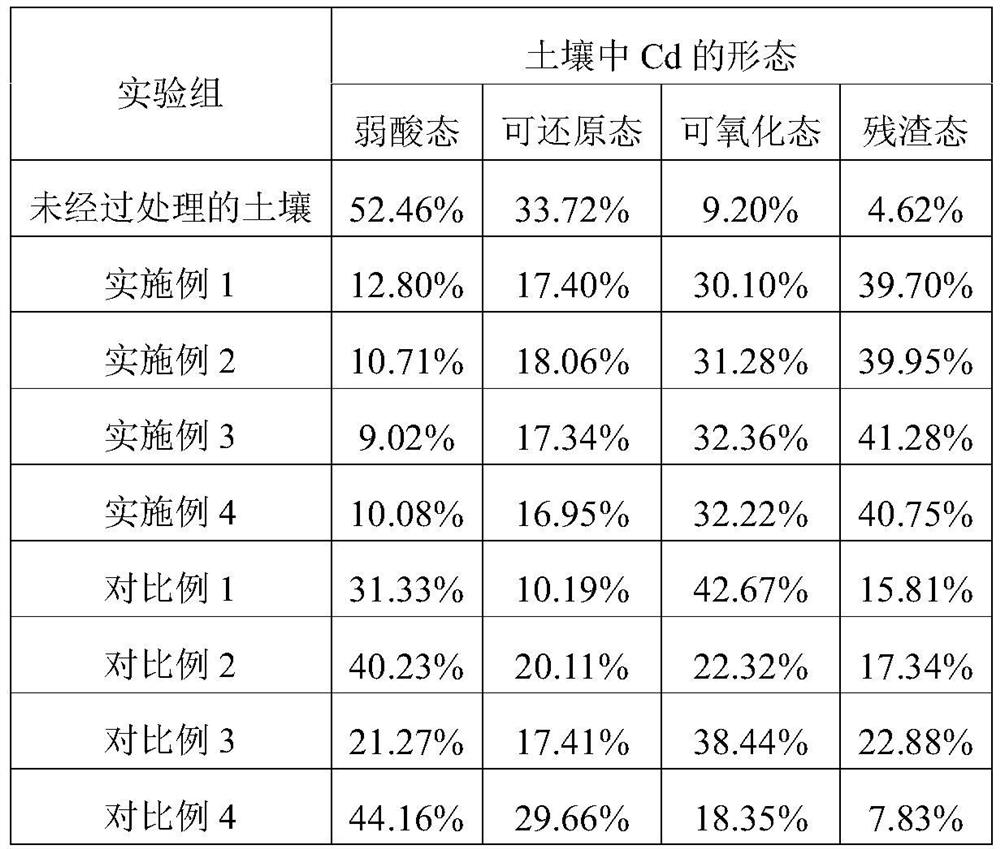

A biochar and modification technology, applied in the field of soil remediation, can solve problems such as late heavy metal pollution in soil, and achieve the effects of reducing the toxicity of heavy metals and achieving a significant effect of Cd remediation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for modifying biochar, comprising the steps of:

[0019] 1) Mix wheat straw and fresh whole cattail plant at a weight ratio of wheat straw: cattail = 1:1, place in a muffle furnace at 600°C for 1 hour with oxygen-limited pyrolysis to form biochar and pulverize it, and fill the muffle furnace with Nitrogen protection;

[0020] 2) prepare the aqueous solution of maleic acid, polyethylene glycol, the content of maleic acid and polyethylene glycol in the aqueous solution of described maleic acid, polyethylene glycol is respectively maleic acid 100g / L, polyethylene glycol 5g / L. The prepared biochar was first soaked in H 2 o 2 The mass percentage content is 10% hydrogen peroxide, the quality of the hydrogen peroxide used for soaking biochar is 6 times of the mass of biochar, filter after soaking for 5 minutes, and then soak the solid phase in the aqueous solution of maleic acid and polyethylene glycol, maleic acid The quality of acid and polyethylene glycol aqueo...

Embodiment 2

[0025] A method for modifying biochar, comprising the steps of:

[0026] 1) Mix wheat straw and fresh whole cattail plant at a weight ratio of wheat straw: cattail = 1:2, place in a muffle furnace at 600°C for 1 hour with oxygen-limited pyrolysis to form biochar and pulverize it, and fill the muffle furnace with Nitrogen protection;

[0027] 2) prepare the aqueous solution of maleic acid, polyethylene glycol, the content of maleic acid and polyethylene glycol in the aqueous solution of described maleic acid, polyethylene glycol is respectively maleic acid 130g / L, polyethylene glycol 8g / L. The prepared biochar was first soaked in H 2 o 2 The mass percentage content is 10% hydrogen peroxide, the quality of hydrogen peroxide used for soaking biochar is 6 times of the mass of biochar, filter after soaking for 6 minutes, and then soak the solid phase in the aqueous solution of maleic acid and polyethylene glycol, maleic acid The quality of acid and polyethylene glycol aqueous s...

Embodiment 3

[0032] A method for modifying biochar, comprising the steps of:

[0033] 1) Mix wheat straw and fresh whole cattail plant at a weight ratio of wheat straw: cattail = 1:2, place in a muffle furnace at 600°C for 1 hour with oxygen-limited pyrolysis to form biochar and pulverize it, and fill the muffle furnace with Nitrogen protection;

[0034] 2) prepare the aqueous solution of maleic acid, polyethylene glycol, the content of maleic acid and polyethylene glycol in the aqueous solution of described maleic acid, polyethylene glycol is respectively maleic acid 180g / L, polyethylene glycol 12g / L. The prepared biochar was first soaked in H 2 o 2 The mass percent content is 10% hydrogen peroxide, the quality of hydrogen peroxide used for soaking biochar is 6 times of the mass of biochar, soaked for 8 minutes, filtered, and the solid phase is soaked in the aqueous solution of maleic acid and polyethylene glycol, maleic acid The quality of acid and polyethylene glycol aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com