Preparation method of organoid spheres

A technology of organoids and spheroids, which is applied in the field of preparation of organoid spheroids, can solve the problems that organoids cannot be prepared in high throughput, affect the accuracy and repeatability of prediction results, and the shape and size of organoids are not uniform, reaching the modeling cycle Short, controllable shape and structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

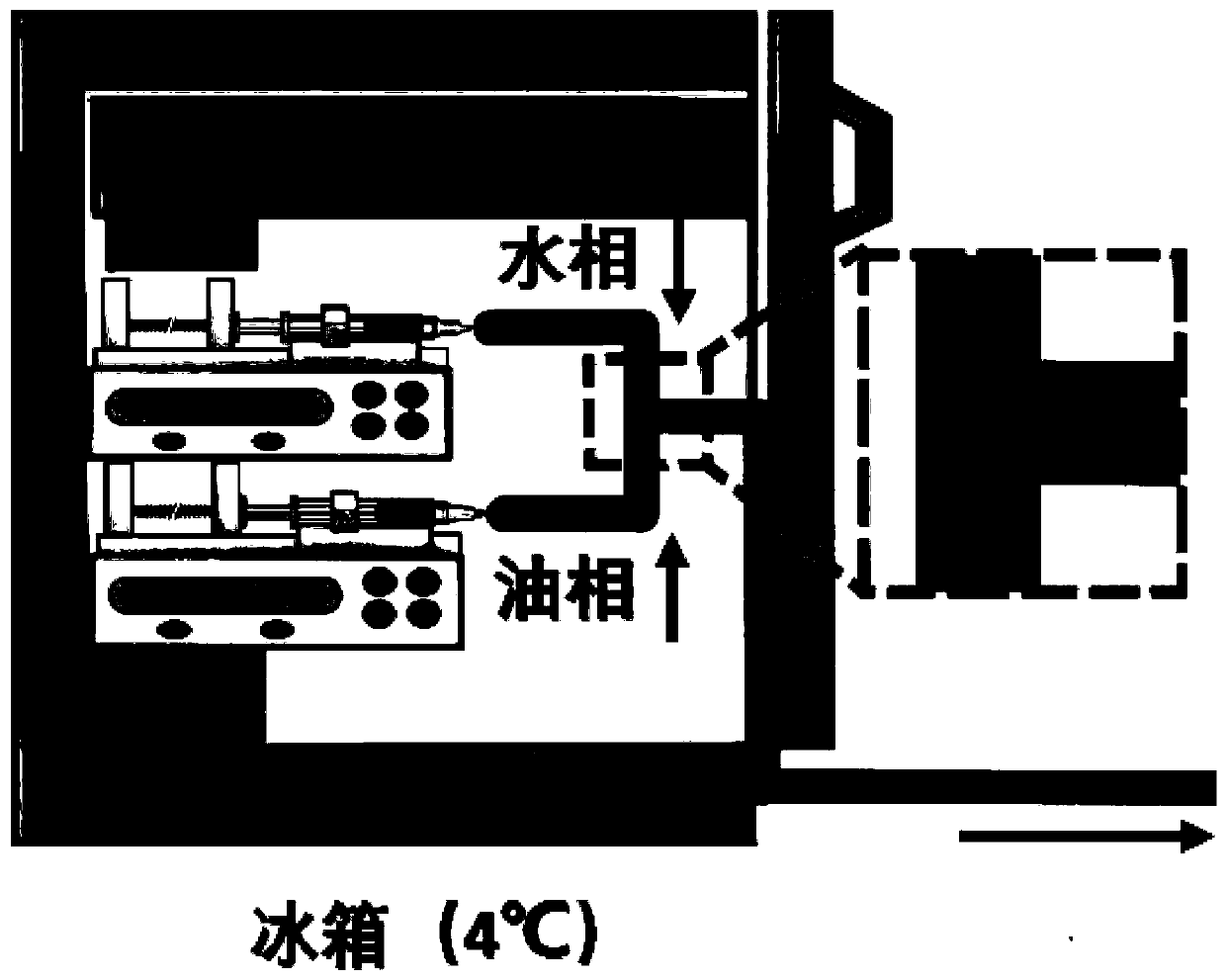

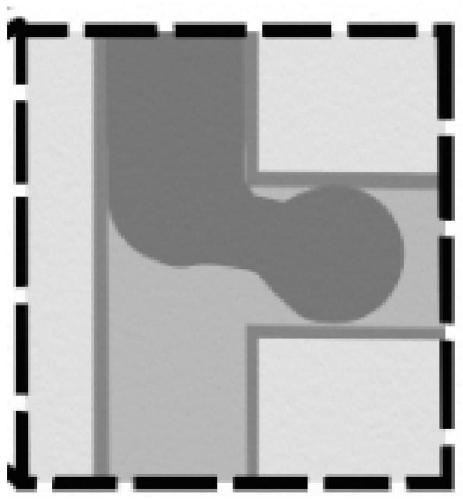

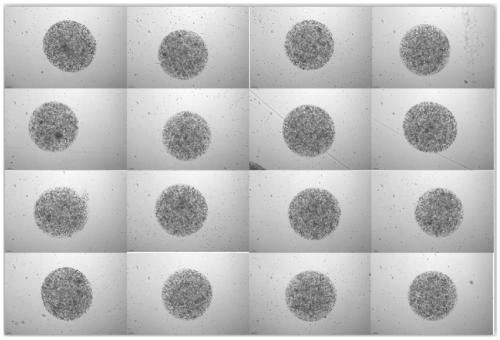

[0049] This embodiment provides a method for preparing organoid spheroids, comprising the following steps:

[0050] Use the primary cell extraction method to extract primary cells, and count the cells; in 4°C environment, 2.0×10 6 Mix one primary cell with 100 μL matrigel, inject it into a 1mL syringe, inject fluorine oil into another syringe, place the fluorine oil and matrigel in two syringe pumps and put them in a 4°C refrigerator; It is a 800μm polytetrafluoroethylene (PTFE) tube, and the two tubes are merged into a polydimethylsiloxane (PMDS) three-way device to obtain cell spheroids, and then the three-way device is connected to another PTFE tube with a diameter of 800 μm, and the entire platform Place in a refrigerator at 4°C; the flow rate of the injection pump containing Matrigel is 20 μL / min, and the flow rate of the fluorine-containing oil injection pump is 50 μL / min, and then the cell spheroids are placed at 37°C with a concentration of 5% CO 2 The solidification ...

Embodiment 2

[0053] This embodiment provides a method for preparing organoid spheroids, comprising the following steps:

[0054] Use the primary cell extraction method to extract primary cells, and count the cells; in an environment of 4°C, 5.0×10 6 Mix one primary cell with 200μL Matrigel, inject it into a 1mL syringe, inject fluorine oil into the other syringe, place the fluorine oil and Matrigel in two syringe pumps and put them in a 4°C refrigerator; It is a 800μm polytetrafluoroethylene (PTFE) tube, and the two tubes are merged into a polydimethylsiloxane (PMDS) three-way device to obtain cell spheroids, and then the three-way device is connected to another PTFE tube with a diameter of 800 μm, and the entire platform Place in a refrigerator at 4°C; the flow rate of the injection pump containing Matrigel is 25 μL / min, and the flow rate of the fluorine-containing oil injection pump is 55 μL / min, and then the cell spheroids are placed at 37°C with a concentration of 5% CO 2 The solidifi...

Embodiment 3

[0056] This embodiment provides a method for preparing organoid spheroids, comprising the following steps:

[0057] Use the primary cell extraction method to extract primary cells and count the cells; in an environment of 4°C, 1.0×10 6 1 primary cell and 80 μL of Matrigel were mixed thoroughly, injected into a 1mL syringe, and the other syringe was injected with fluorine oil. The fluorine oil and Matrigel were respectively placed in two syringe pumps and placed in a 4°C refrigerator; the syringes were respectively connected with diameters It is a 600μm polytetrafluoroethylene (PTFE) tube. The two tubes are merged into a polydimethylsiloxane (PMDS) three-way device to obtain cell spheroids, and then the three-way device is connected to another PTFE tube with a diameter of 600 μm. The entire platform Place in a refrigerator at 4°C; the flow rate of the injection pump containing Matrigel is 15 μL / min, and the flow rate of the fluorine-containing oil injection pump is 45 μL / min, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com