Preparation method of biopolymer electrolyte with water as solvent

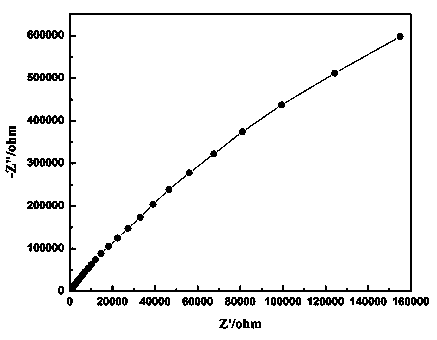

A biopolymer and electrolyte technology, applied in the field of biopolymer electrolyte preparation, can solve the problems of excessive pore size and low solid-state conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

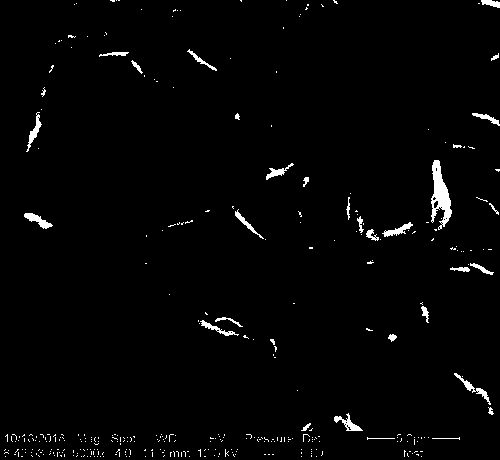

[0016] Embodiment 1, a method for preparing a biopolymer electrolyte using water as a solvent, is characterized in that it is carried out according to the following steps:

[0017] Step 1: Put 0.5g of cellulose acetate and 0.1g of hydroxyethylcellulose in a beaker, add 30ml of deionized water, and stir for 12 hours.

[0018] Step 2: Dissolve 0.6g of urea, 0.4g of choline chloride and 0.2g of glycerin in a weighing bottle, and heat in a water bath to dissolve until colorless and transparent.

[0019] Step 3: Add the deep eutectic solvent obtained in step 2 to the mixed solution obtained in step 1, stir for 6 hours, add lithium salt and continue stirring for 6 hours, place it in a petri dish at room temperature to let the air bubbles out, and wait for the air bubbles to be removed Then put it into a vacuum oven and dry it for 15 hours to prepare a film.

[0020] This embodiment is carried out in a closed beaker and a weighing bottle, which effectively avoids the volatilization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com