Method for decelerating vacuum cleaner motor

A vacuum cleaner and motor controller technology, which is applied in the direction of single motor speed/torque control, generator control, motor generator control, etc., can solve the problem of long deceleration time, increase the use time, improve user experience, and shorten deceleration the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

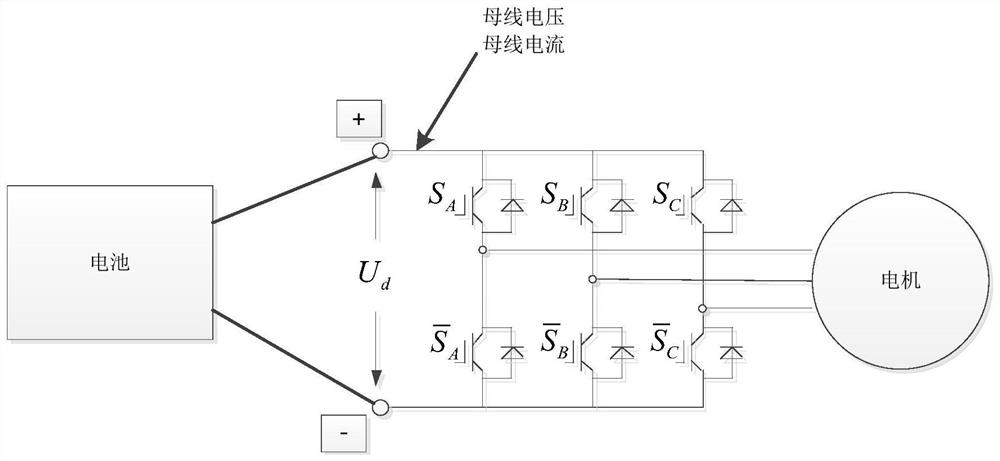

[0023] Such as figure 1 Shown is a schematic diagram of the inverter part of a vacuum cleaner motor controller of the present invention, including a three-phase permanent magnet synchronous motor, a power supply battery and a motor controller, and the single-chip microcomputer on the motor controller controls 6 switching tubes to switch regularly. The motor runs. The "bus voltage" and "bus current" of the motor controller are equal to the voltage and current of the battery.

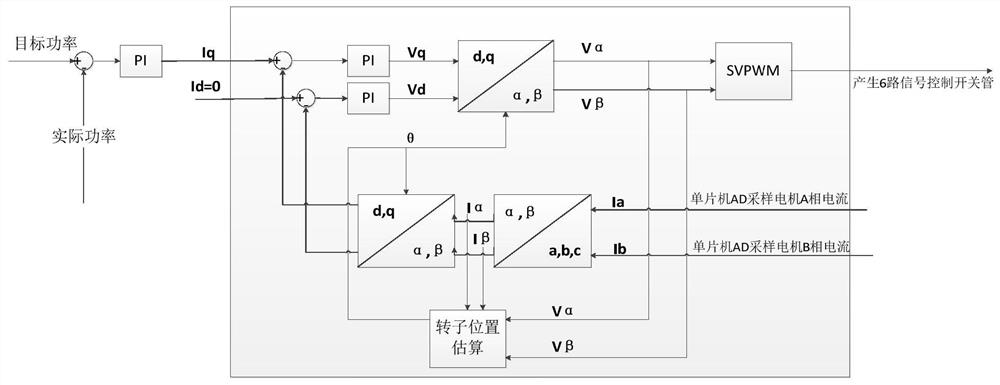

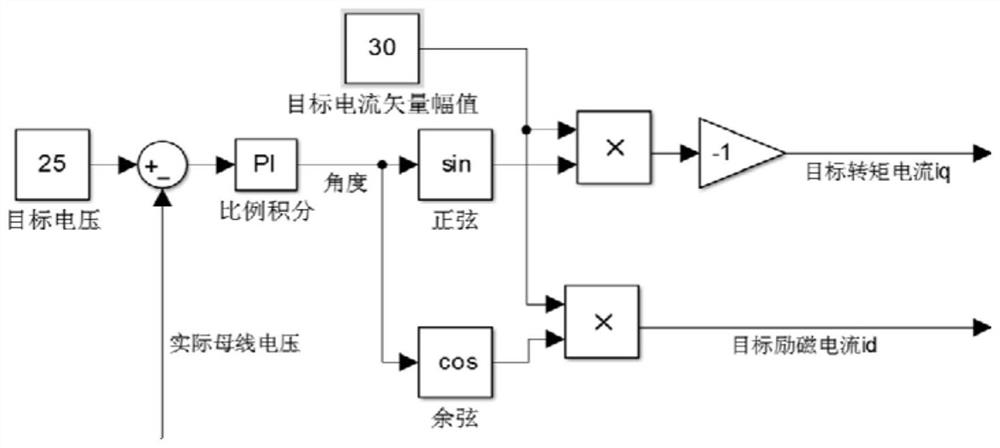

[0024] Such as figure 2 Shown is the vector control algorithm when the motor is running normally, and this algorithm is common. The input to the algorithm is the target torque current i d and the targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com