Combined dehydration method for preparing dried tomatoes

A technology of dried tomato and tomato, which is applied in the field of combined dehydration preparation of dried tomato, which can solve problems such as microbial contamination, and achieve the effects of short processing cycle, reduced strength, and maintaining the original style and nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

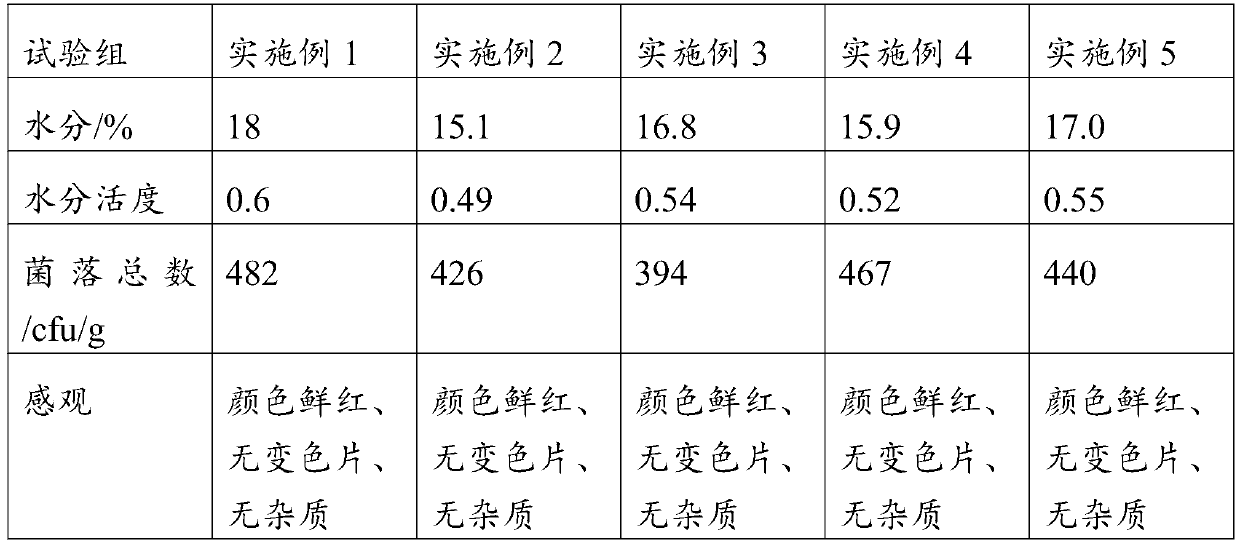

Examples

Embodiment 1

[0030] A combined dehydration preparation method of dried tomato, comprising the following steps:

[0031] (1) Selection and cleaning: After picking out the ripe tomatoes and cleaning them, use steam blanching to peel the skins. For blanching and peeling, first soak the tomatoes in ice water for 10 minutes, and then put the tomatoes in 100°C steam Blanch for 10s, take it out and peel it directly;

[0032] (2) Pre-dehydration by salting: add 0.1% salt to the peeled tomatoes, mix well and let stand for salting for 30 minutes, then separate the tomatoes from the salt water;

[0033] (3) Hot air drying: Send the salted tomatoes into the dryer for a hot air drying, take out the dried tomatoes and place them in a tumbler for vacuum tumbling, and then send them into the dryer for a second hot air drying to obtain dryness The tomato after: the temperature of primary hot air drying is 50 ℃, and the wind speed of drying is 2m / s, and the time of this primary hot air drying is 3h, and th...

Embodiment 2

[0038] A combined dehydration preparation method of dried tomato, comprising the following steps:

[0039] (1) Selection and cleaning: pick out the ripe tomatoes and clean them, then peel them with steam blanching. For blanching and peeling, first soak the tomatoes in ice water for 15 minutes, and then put the tomatoes in 100°C steam Blanch for 20s, take it out and peel it directly;

[0040] (2) Pre-dehydration by salting: add 1% salt to the peeled tomatoes, mix well and let stand for salting for 120 minutes, then separate the tomatoes from the salt water;

[0041] (3) Hot air drying: Send the salted tomatoes into the dryer for a hot air drying, take out the dried tomatoes and place them in a tumbler for vacuum tumbling, and then send them into the dryer for a second hot air drying to obtain dryness The tomato after: the temperature of primary hot air drying is 60 ℃, and the wind speed of drying is 3m / s, and the time of this primary hot air drying is 5h, and the water content...

Embodiment 3

[0046] A combined dehydration preparation method of dried tomato, comprising the following steps:

[0047] (1) selection and cleaning: after the ripe tomatoes are selected and cleaned, acupuncture treatment is carried out;

[0048] (2) Pre-dehydration by salting: add 0.5% salt to the tomato after acupuncture, mix well and leave to stand for salting for 60 minutes, then separate the tomato from the salt water;

[0049] (3) Hot air drying: Send the salted tomatoes into the dryer for a hot air drying, take out the dried tomatoes and place them in a tumbler for vacuum tumbling, and then send them into the dryer for a second hot air drying to obtain dryness After the tomato; the temperature of the first hot air drying is 55 ℃, the drying wind speed is 2m / s, the time of the first hot air drying is 4h, and the water content of the tomato obtained by the first hot air drying is 80%, the rotating speed of the vacuum tumbling The tumbling time is 5r / min, the tumbling time is 20min, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com