Desalinated soy sauce residues, and method for removing salinity from soy sauce residues and recovering protein

A technology for soy sauce residue and protein is applied in the fields of desalting soy sauce residue, removing salt in soy sauce residue and recovering protein. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

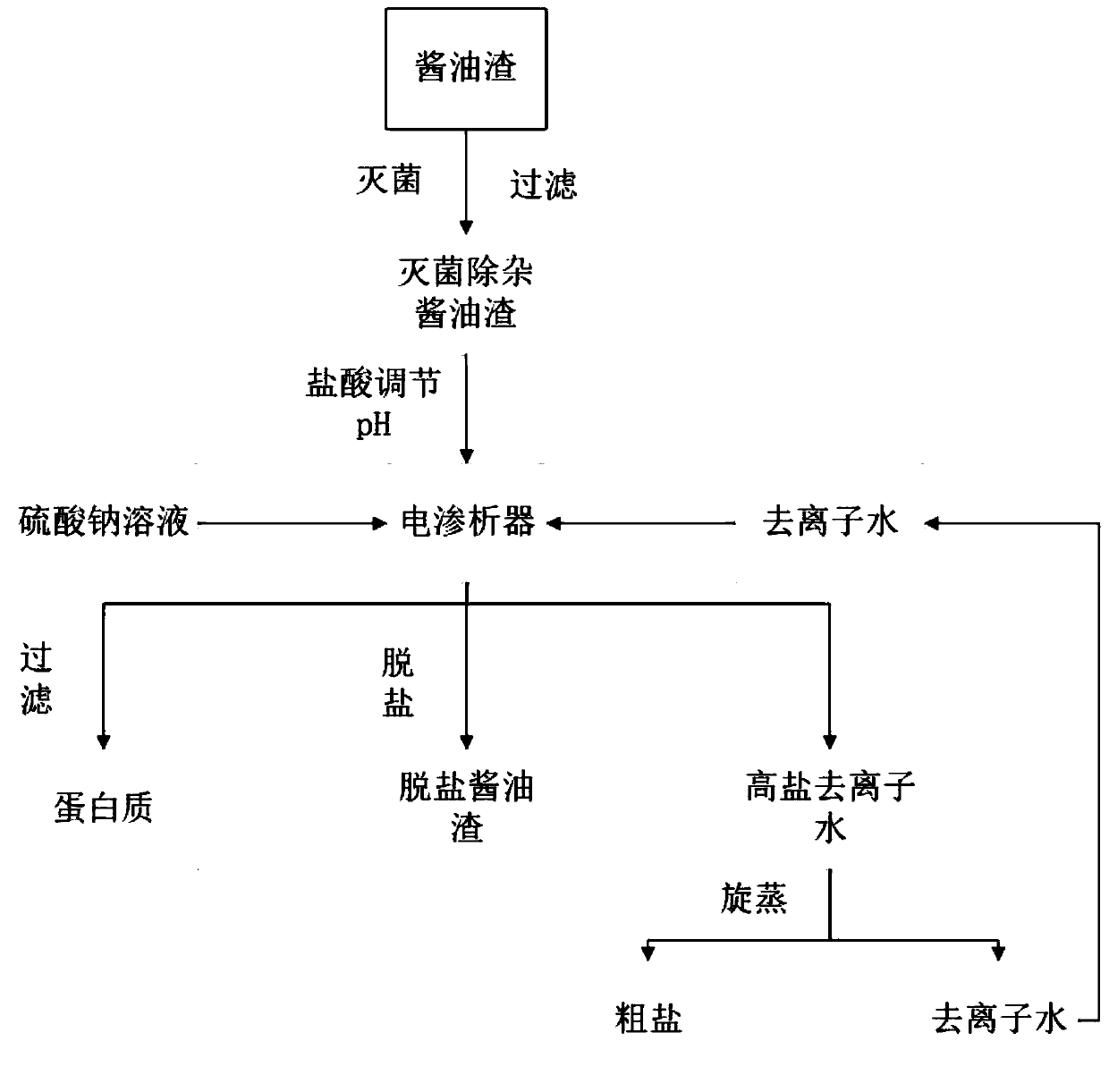

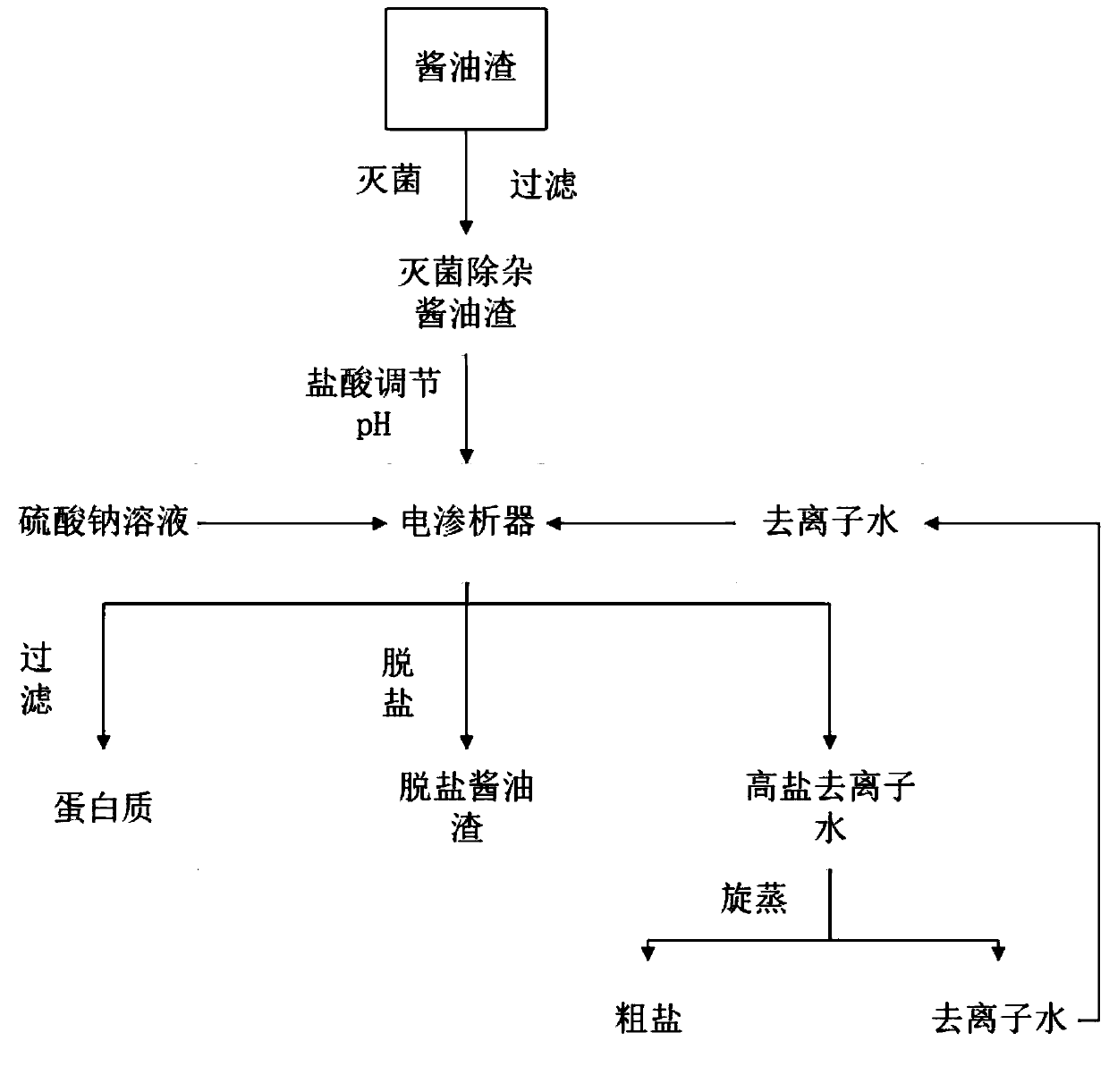

Method used

Image

Examples

Embodiment 1

[0030] 666ml of soy sauce residue is added to the weak chamber of the electrodialyzer, the volume of the added soy sauce residue is 33.3% of the light chamber, and the pH is adjusted to be 4, 500ml of deionized water is added to the concentrated chamber of the electrodialyzer, and the added deionized water The volume is 25% of the concentrated chamber, and 666ml of sodium sulfate solution is added to the electrode chamber of the electrodialyzer, and the volume of the added sodium sulfate solution is 33.3% of the electrode chamber; open the electrodialyzer, desalinate at normal temperature, the desalting voltage is 7V, and the desalination cycle The flow rate is 2.1cm / s, and the desalination time is 10min. After the desalination is completed, the precipitate in the thin chamber is the recovered protein, and the rest is desalted soy sauce residue. The solution in the thick chamber is rotary evaporated to obtain the desalted.

[0031] The desalination rate of Example 1 was 15%, an...

Embodiment 2

[0033] 500ml of soy sauce residue is added to the weak chamber of the electrodialyzer, the volume of the added soy sauce residue is 25% of the light chamber, and the pH is adjusted to 4.4, 1000ml of deionized water is added to the concentrated chamber of the electrodialyzer, and the added deionized water The volume is 50% of the concentrated chamber, and 750ml of sodium sulfate solution is added to the electrode chamber of the electrodialyzer, and the volume of the added sodium sulfate solution is 37.5% of the electrode chamber; open the electrodialyzer, desalinate at normal temperature, the desalting voltage is 8V, and the desalination cycle The flow rate is 2.7cm / s, and the desalination time is 20min. After the desalination is completed, the precipitate in the thin chamber is the recovered protein, and the rest is desalted soy sauce residue. The solution in the thick chamber is rotary evaporated to obtain the desalted.

[0034] The desalination rate of Example 2 was 55%, and ...

Embodiment 3

[0036] 500ml of soy sauce residue is added to the weak chamber of the electrodialyzer, and the volume of the added soy sauce residue is 25% of the light chamber and the pH is adjusted to be 4.8. 1500ml of deionized water is added to the concentrated chamber of the electrodialyzer, and the volume of the added deionized water is is 75% of the concentrated chamber, add 1000ml of sodium sulfate solution to the electrode chamber of the electrodialyzer, the volume of the added sodium sulfate solution is 50% of the electrode chamber; open the electrodialyzer, desalinate at room temperature, the desalting voltage is 9V, and the desalting circulation flow rate The desalination time is 2.7cm / s, and the desalination time is 30min. After the desalination is completed, the precipitate in the desalination chamber is the recovered protein, and the rest is desalted soy sauce residue. The solution in the concentration chamber is rotary evaporated to obtain the desalted salt.

[0037] The desali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com