Magnetic composite non-woven filter bag for removing magnetic fine particles and preparation method of filter bag

A magnetic and filter bag technology, which is applied in the field of magnetic composite non-woven filter bag for removing magnetic fine particles and its preparation, can solve the problems of low collection efficiency, achieve improved removal effect, high temperature resistance and flame retardancy, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

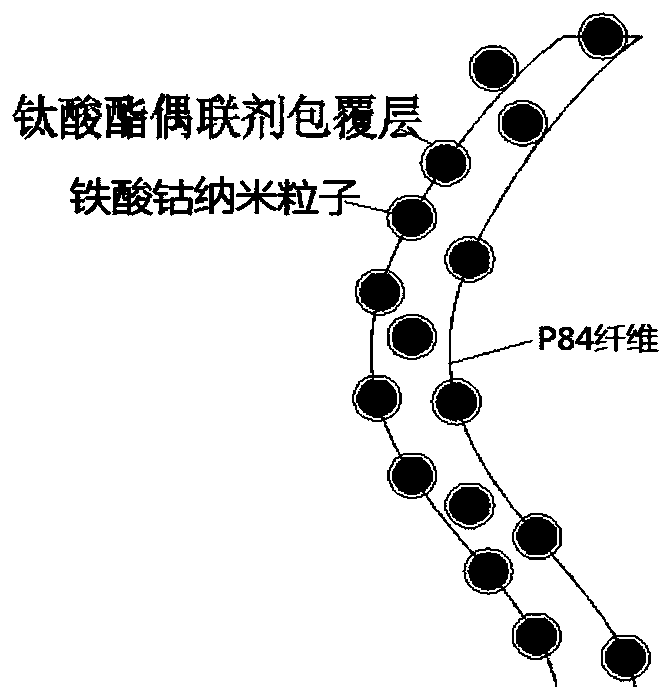

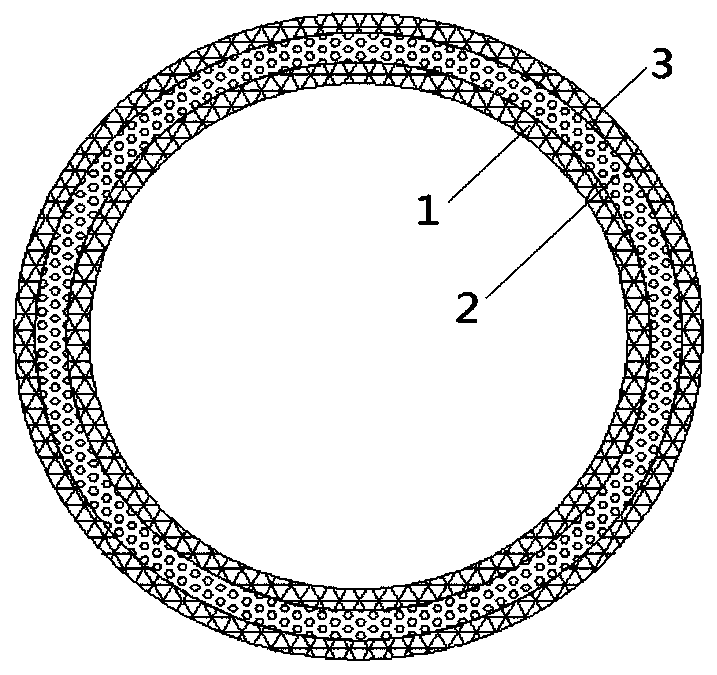

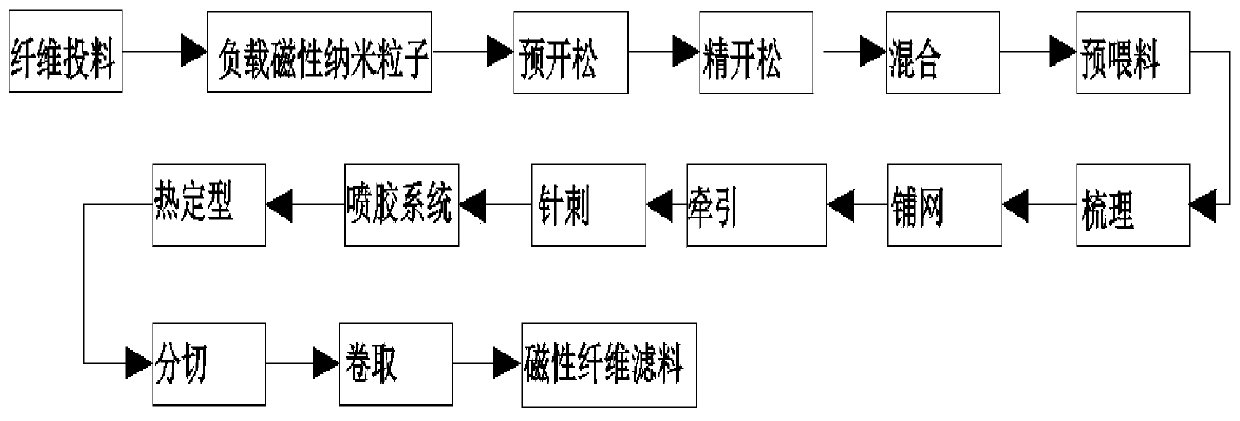

[0040] 42.2 g of P84 fibers with a diameter of 15 μm were soaked in 5% HCL solution for 5 hours, washed with deionized water three times, dried at 50° C. for 6 hours, and then used. Then put 2000ml of deionized water and absolute ethanol (2:1 molar ratio) in the constant temperature reaction tank (HH-4), adjust the pH of the solution to 1~2 with hydrochloric acid, and then put 22.5g of cobalt ferrite nano Particles (particle size: 50nm) and 4.5g titanate coupling agent NDZ-201, the solution was ultrasonically dispersed for 30min, then put into the pretreated P84 fiber, then shaken at a speed of 700r / min for 12h, and then passed Filter, wash with deionized water and absolute ethanol repeatedly for 3 times, and dry at 50°C for 12 hours to obtain magnetic P84 fibers loaded with magnetic cobalt ferrite nanoparticles, followed by pre-opening, fine opening, mixing, pre-feeding, and carding , net laying, traction, acupuncture, glue spraying system, heat setting, slitting, coiling, an...

Embodiment 2

[0051] First, the P84 fiber with a diameter of 15 μm was soaked in a 5% HCL solution for 5 hours, washed with deionized water, dried, and then put into the reaction tank (HH-4) with deionized water and absolute ethanol ( The molar ratio is 2:1), adjust the pH of the solution to 2 with hydrochloric acid, then add quantitative cobalt ferrite nanoparticles (particle size: 50nm) and pretreated P84 fibers, and add an appropriate amount of titanate coupling agent to the mixed solution NDZ-201, the ratio of P84 fiber, cobalt ferrite particles, coupling agent and absolute ethanol: 1g:0.1g:0.03g:5ml. Then ultrasonically disperse the solution for 30 minutes, shake it at a speed of 700r / min for 12 hours, then filter, wash with deionized water and absolute ethanol for 3 times, and dry at 50°C for 12 hours to obtain magnetically loaded cobalt ferrite nanoparticles. magnetic P84 fiber. Then, the film-coated fiber, magnetic P84 fiber and short PTFE fiber are 15%:70%:15% by weight, respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com