Process for preparing earthworm-feces organic fertilizer

A technology of manure organic fertilizer and preparation process, which is applied in the direction of preparation of organic fertilizer, organic fertilizer, and bio-organic part treatment, etc. It can solve the problems of crop root burning and expensive vermicompost, so as to improve fertilizer efficiency, facilitate growth, and accelerate The effect of fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation technology of vermicompost organic fertilizer of the present invention comprises the following steps:

[0032] S1. Raising earthworms with organic feed and obtaining earthworm excrement;

[0033] S2, crushing and stirring the earthworm excrement in step S2 to obtain earthworm excrement with uniform particle size;

[0034] S3. Add the earthworm excrement with uniform particle size and starter in the step S3 to the mixer according to the proportion to mix to obtain the earthworm excrement fermentation base material, transfer the earthworm excrement fermentation base material to the fermenter for sealing and fermentation to obtain earthworm excrement fertilizer; earthworm excrement and The weight ratio of the starter is 1:0.01-0.03;

[0035] S4. Obtain the following raw materials in parts by weight: 10-20 parts of poultry manure, 0.2-0.6 parts of bran, 0.1-0.3 parts of bone meal, 20-30 parts of corn, 23-46 parts of traditional Chinese medicine residue, 10-...

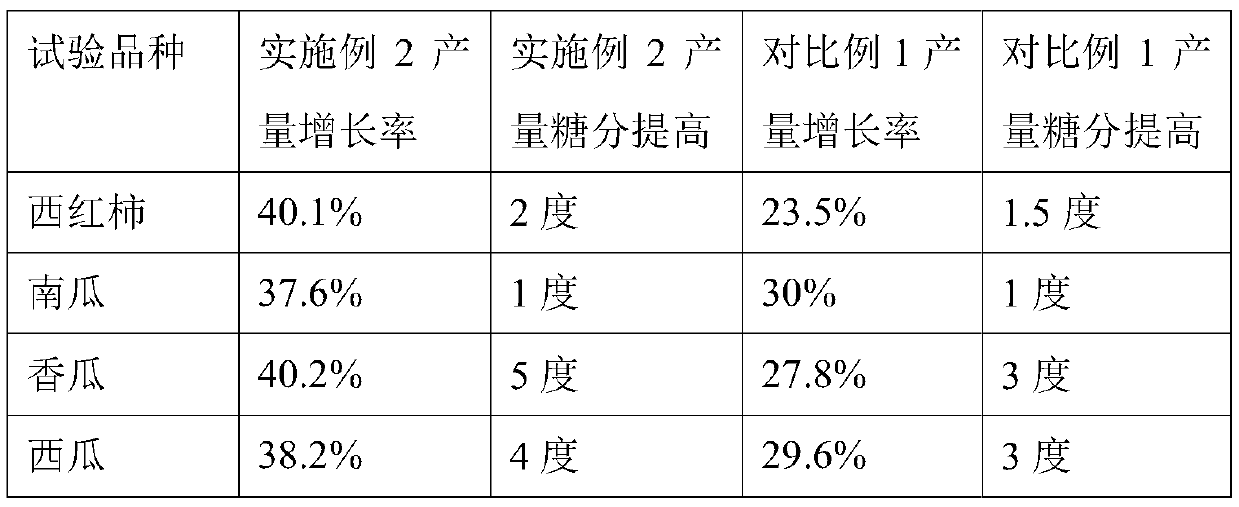

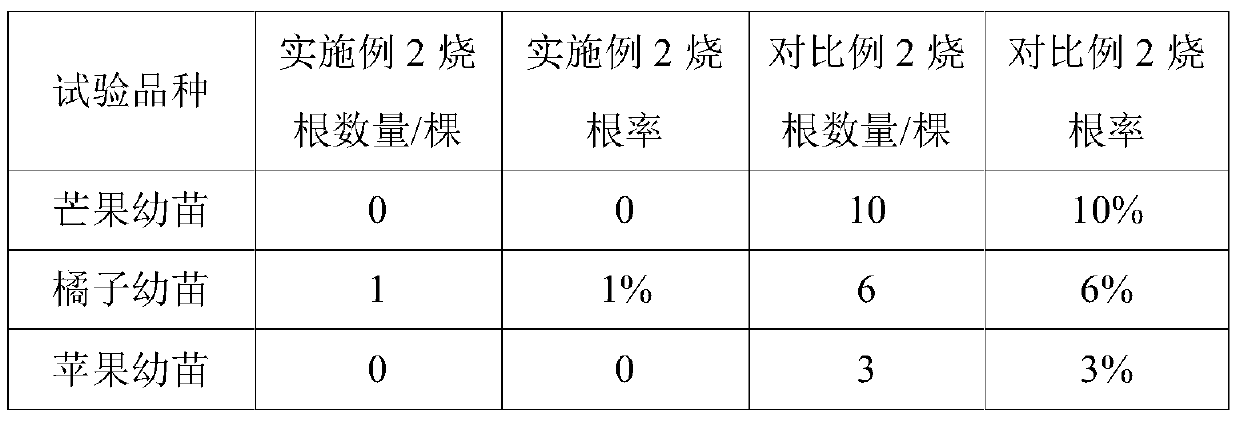

Embodiment 2

[0042] Based on above-mentioned embodiment, the preparation technology of vermicompost organic fertilizer of the present invention comprises the following steps:

[0043] S1. Raising earthworms with organic feed and obtaining earthworm excrement;

[0044] S2, crushing and stirring the earthworm excrement in step S2 to obtain earthworm excrement with uniform particle size;

[0045] S3. Add the earthworm excrement and starter with uniform particle size in step S3 to the mixer according to the proportion and mix them to obtain the earthworm excrement fermentation base material, transfer the earthworm excrement fermentation base material to the fermenter for sealing and fermentation to obtain earthworm excrement fertilizer; earthworm excrement and The weight ratio of starter is 1:0.027;

[0046] S4. Obtain the following raw materials in parts by weight: 15 parts of poultry manure, 0.45 part of bran, 0.2 part of bone meal, 30 parts of corn, 40 parts of traditional Chinese medicine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com