Water retaining agent used for desert greening as well as preparation method and application of water retaining agent

A water-retaining agent and desert technology, applied in chemical instruments and methods, applications, and other chemical processes, to achieve the effects of improving radiation dose utilization and production efficiency, increasing porosity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: prepare desert greening water-retaining agent

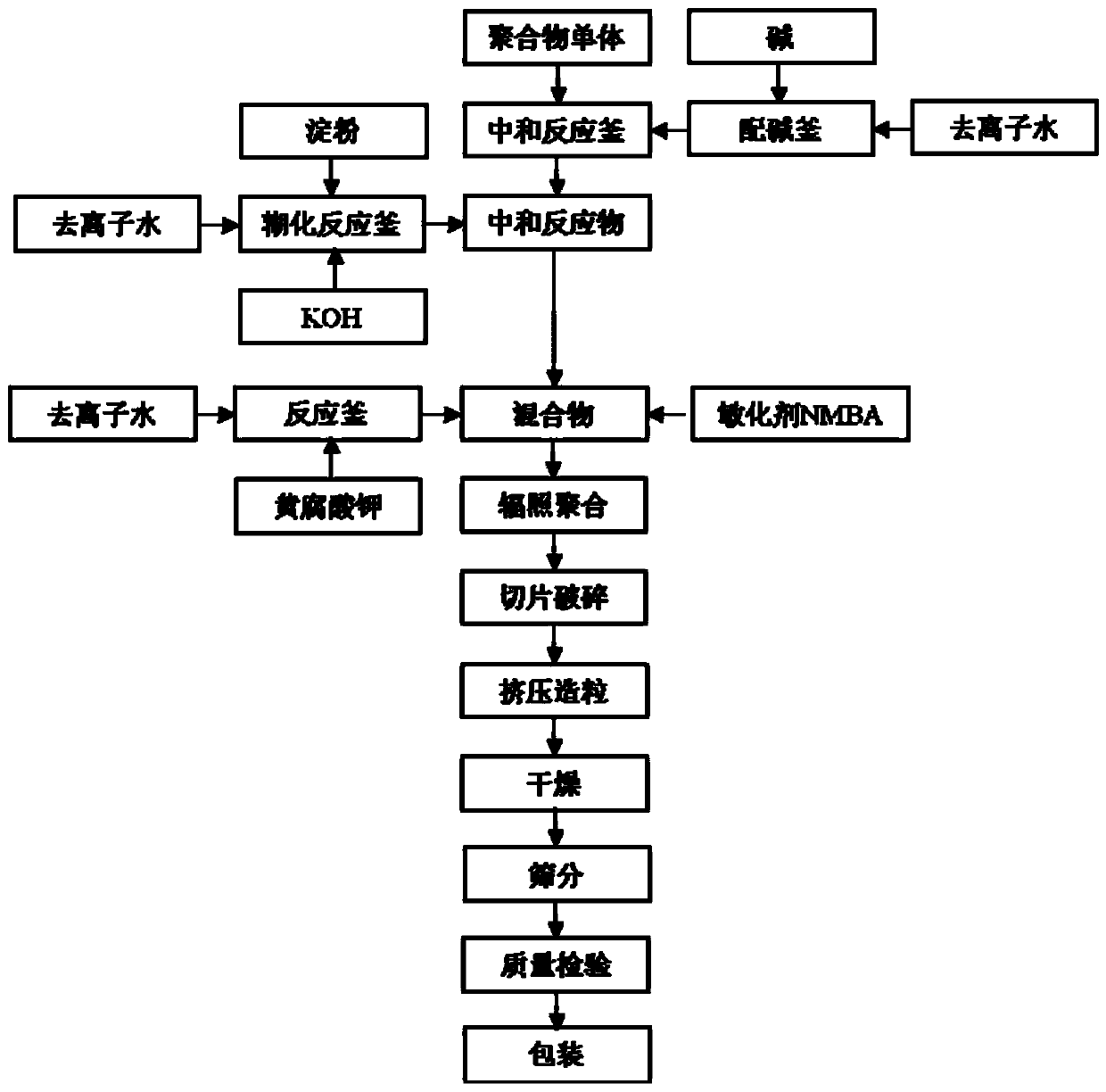

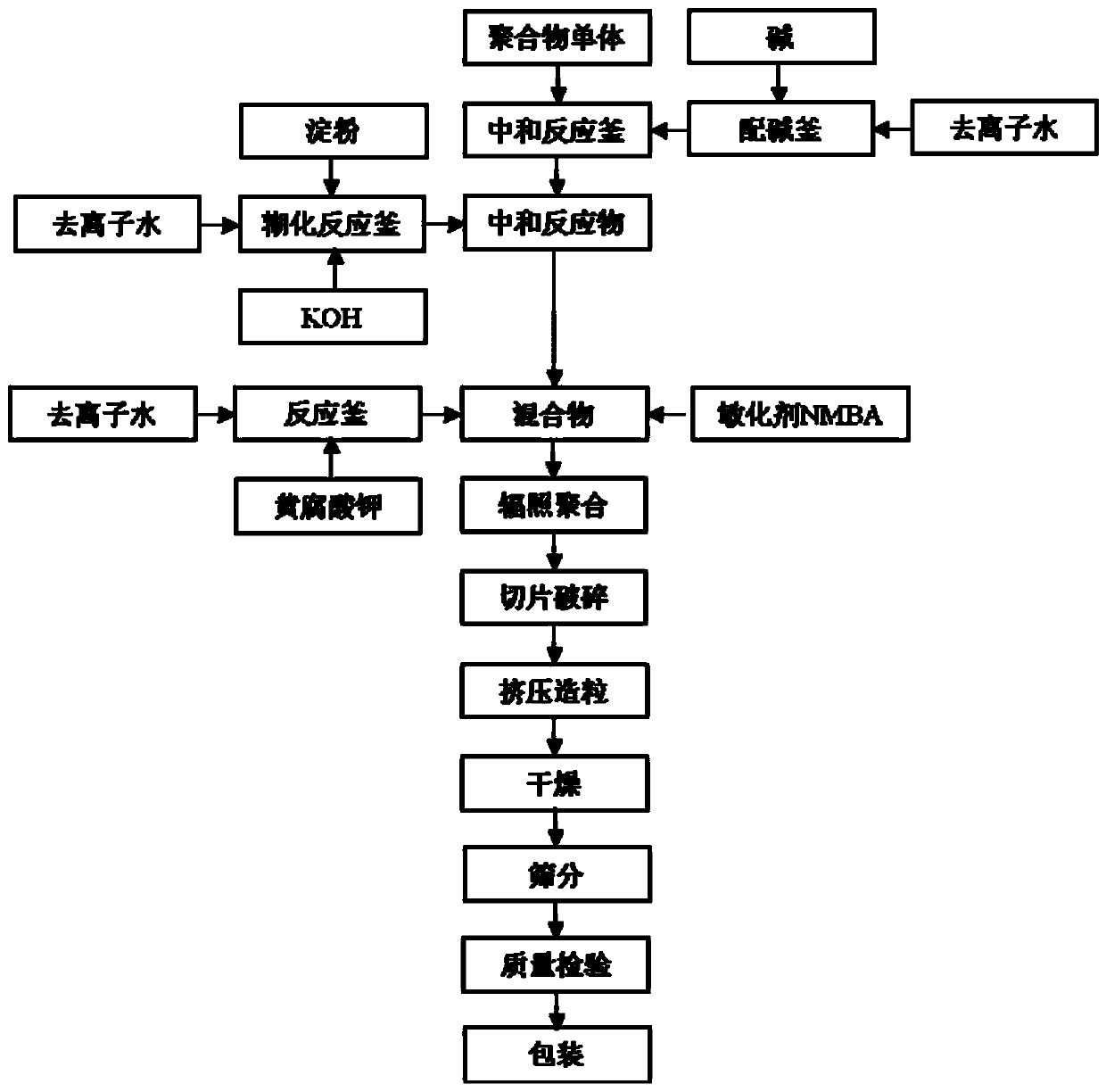

[0077] see figure 1 The preparation process flow diagram of the water-retaining agent for desert greening shown.

[0078] (1) Alkaline solution preparation

[0079] Add 240kg of potassium carbonate solid into the cauldron for alkali preparation, add deionized water to dissolve it under stirring, and cool to room temperature for later use.

[0080] (2) Neutralization

[0081] Put 300kg of acrylic acid into the neutralization reactor, and under agitation, slowly send the potassium carbonate solution in (1) to the neutralization reactor through a delivery pump, and cool to room temperature after the neutralization reaction is completed for use.

[0082] (3) starch gelatinization

[0083] Put 100kg of corn starch into the starch gelatinization reactor, add a certain amount of deionized water with a delivery pump, turn on the stirring device, add 0.5 KOH, gelatinize in a 40°C water bath for 40min, and cool to ...

Embodiment 2

[0094] Embodiment 2: prepare desert greening water-retaining agent

[0095] see figure 1 The preparation process flow diagram of the water-retaining agent for desert greening shown.

[0096] (1) Alkaline solution preparation

[0097] Put 200kg of solid ammonium carbonate into the alkali mixing tank, add deionized water under stirring to dissolve it, and cool to room temperature for later use.

[0098] (2) Neutralization

[0099] Put 300kg of acrylic acid into the neutralization reactor, and under agitation, slowly send the ammonium carbonate solution in (1) to the neutralization reactor through a delivery pump, and cool to room temperature after the neutralization reaction is completed for use.

[0100] (3) starch gelatinization

[0101] Put 120kg of tapioca starch into the starch gelatinization reactor, add a certain amount of deionized water with a delivery pump, turn on the stirring device, add 2.4kg of KOH, gelatinize in a water bath at 50°C for 30min, and cool to room...

Embodiment 3

[0112] Embodiment 3: prepare desert greening water-retaining agent

[0113] see figure 1 The preparation process flow diagram of the water-retaining agent for desert greening shown.

[0114] (1) Alkaline solution preparation

[0115] In the cauldron with alkali, drop into the ammoniacal liquor of 270kg stand-by.

[0116] (2) Neutralization

[0117] Put 300kg of acrylic acid into the neutralization reactor, and under the condition of stirring, slowly send the ammonia water in (1) to the neutralization reactor through the transfer pump, and cool to room temperature after the neutralization reaction is finished for use.

[0118] (3) starch gelatinization

[0119] Put 80kg of potato starch into the starch gelatinization reactor, add a certain amount of deionized water with a delivery pump, turn on the stirring device, add 1.6kg of KOH, gelatinize in a water bath at 30°C for 60min, and cool to room temperature.

[0120] (4) Mixed packing

[0121] Pump the potato starch paste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com