Alternating current power generator

A technology of alternators and generators, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that alternators cannot realize vibration power generation, and achieve the effect of increasing power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

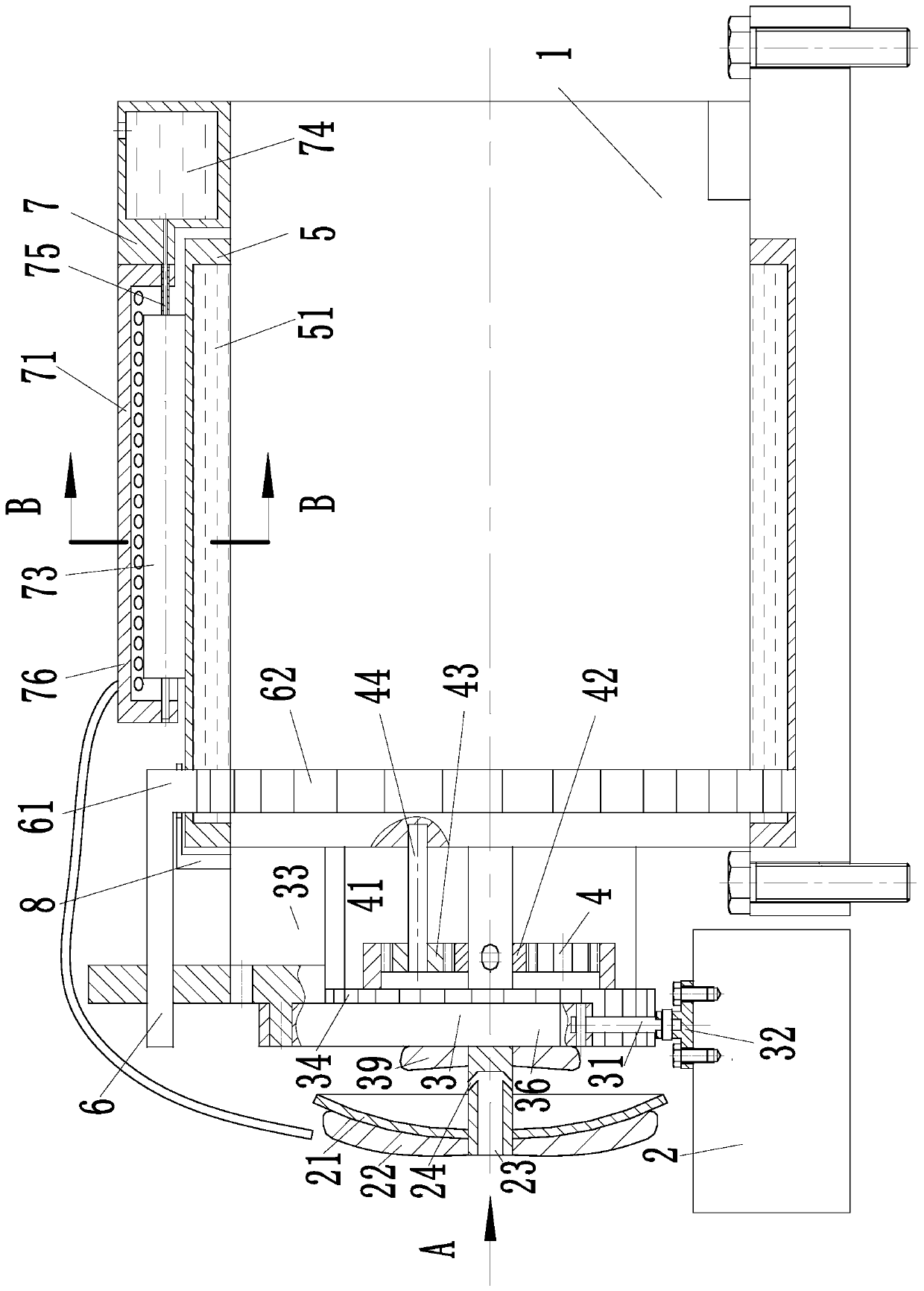

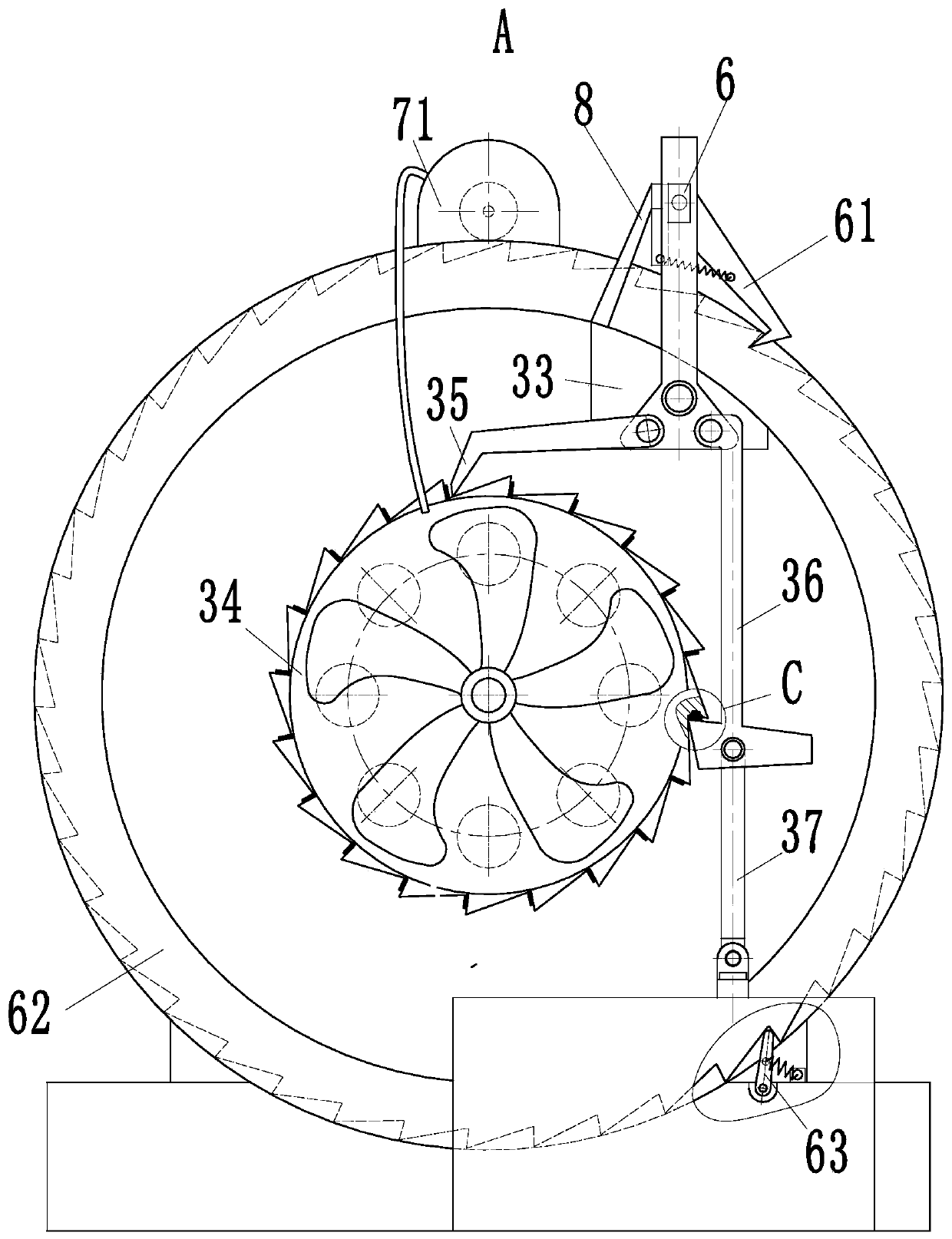

[0023] As a specific embodiment of the present invention, a casing 5 is provided outside the generator 1, and the casing 5 can rotate along the circumferential direction of the generator 1, and an insulating oil 51 is arranged between the casing 5 and the outer surface of the generator 1; The top of the No. 2 connecting rod 37 is provided with a No. 1 chute 6, and the central axis of the No. 1 chute 6 is along the horizontal direction; the inside of the No. 1 chute 6 is provided with a No. 3 driving pawl 61, and the outer shell 5 No. 2 ratchet 62 is arranged on the surface, No. 3 driving pawl 61 can push No. 2 ratchet 62 to rotate, and the bottom of housing 5 is provided with non-return ratchet 63, and non-return ratchet 63 cooperates with No. 2 ratchet 62; When the ambient temperature on one side of the generator 1 is quite different from the ambient temperature on the other side, the No. 2 connecting rod 37 can drive the No. 2 ratchet 62 to move through the No. 3 drive pawl 6...

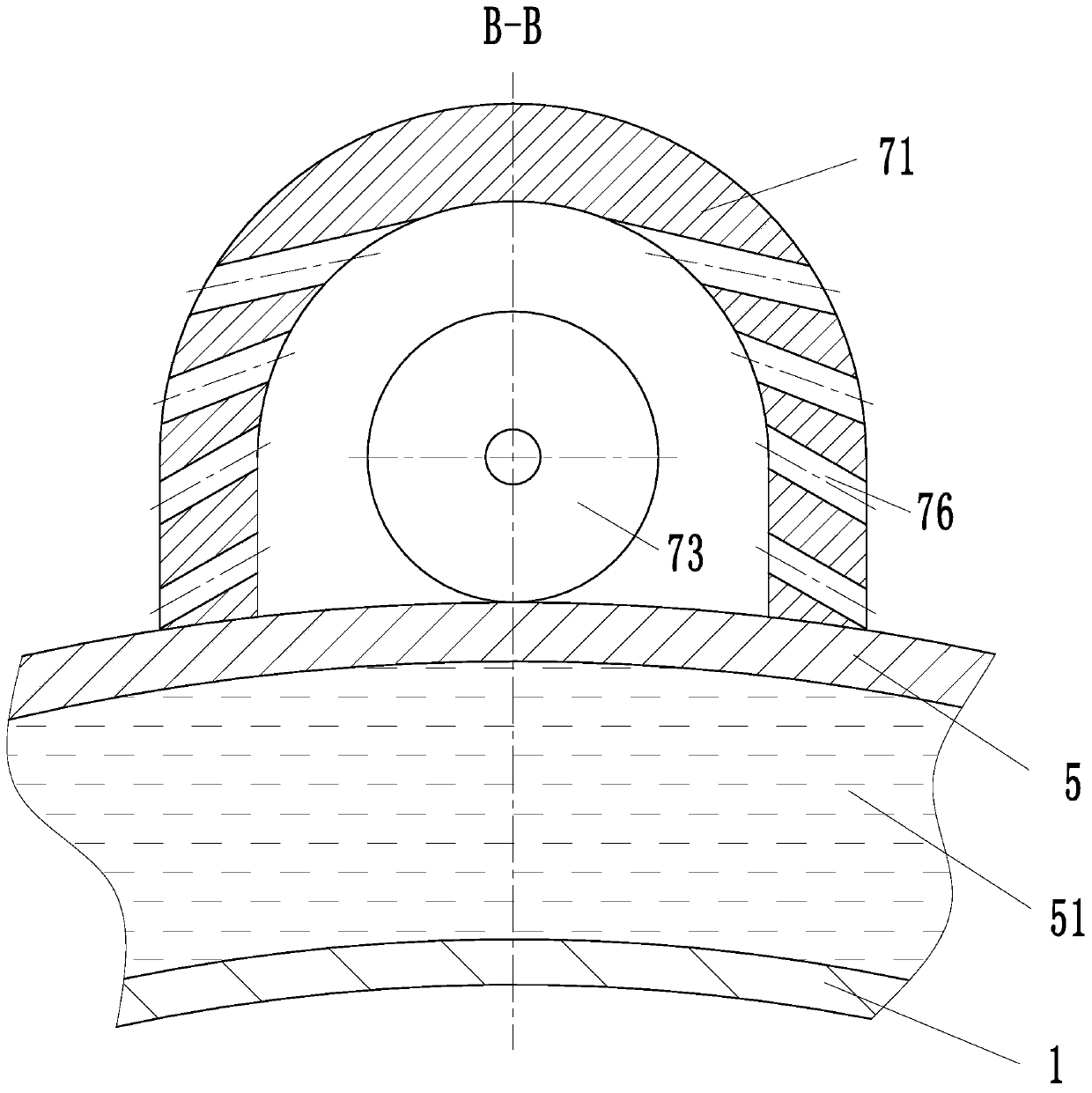

Embodiment approach

[0024] As a specific embodiment of the present invention, the upper right side of the generator 1 is provided with a fixed support 7, and the fixed support 7 is fixedly connected with the outer surface of the generator 1; the left side of the fixed support 7 is provided with a sponge Bearing 71, the shape of sponge bearing 71 is a semi-hollow cylinder, and the right side of described sponge bearing 71 is connected with fixed bearing 7; The inside of sponge bearing 71 is provided with sponge 73, and the shape of described sponge 73 It is a cylinder, and the sponge 73 is rotatably connected with the sponge support 71; the inside of the fixed support 7 is provided with a water storage chamber 74; The chamber 74 is connected to the sponge 73 through the water pipe 75; during work, the mixed solution of the antirust agent and the weak acid reagent in the water storage chamber 74 flows to the sponge 73 through the water pipe 75, and the antirust agent such as ethanolamine and acid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com