Method for preparing bulk molybdenum disulfide surface Raman-enhanced substrate through femtosecond lasers

A surface Raman-enhanced, molybdenum disulfide technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of complicated plasma treatment process, difficult preparation of molybdenum disulfide samples, low efficiency, etc. The effect of convenient process, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

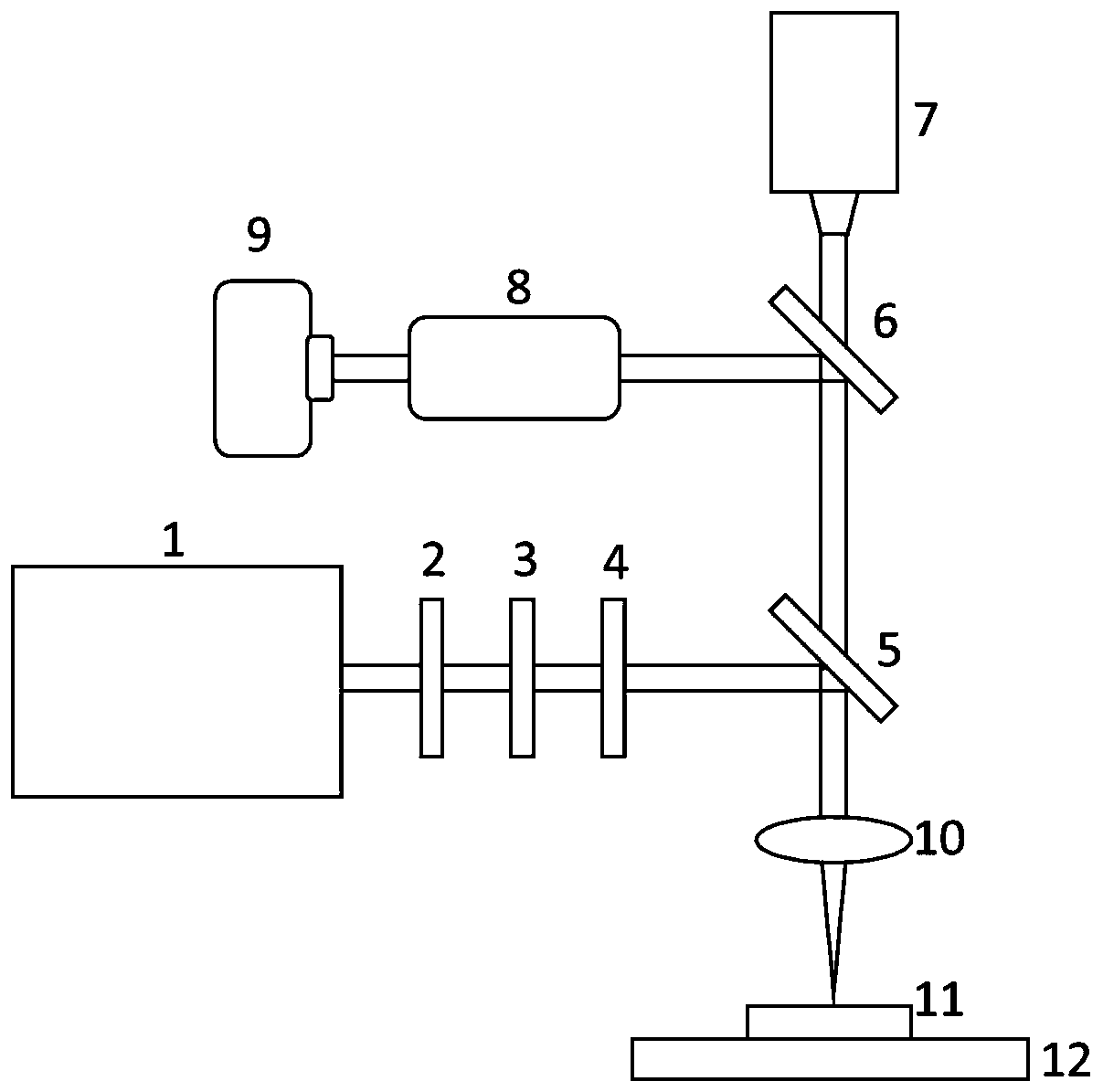

[0023] A method for preparing a Raman-enhanced substrate on the surface of bulk molybdenum disulfide by femtosecond laser, the specific steps are as follows:

[0024] Step 1: Peel off the bulk molybdenum disulfide sample 11 with adhesive tape, paste it on the glass slide, and fix the glass slide on the six-dimensional mobile platform 12;

[0025] Step 2: Adjust the optical path of the femtosecond laser system 1 to ensure that the laser can be vertically incident on the surface of the horizontally placed sample 12;

[0026] Step 3: Adjust the half-wave plate 2 to make the laser power reach 8mW, and set the femtosecond laser system 1 to single-pulse trigger mode;

[0027] Step 4: Imaging is carried out by means of the imaging CCD 9 and the white light source 7, and the surface morphology and processing process of the processed material are observed. With the on-off of the mechanical switch 4, the processing can be performed on the sample surface 11 at a specified area and at a s...

Embodiment 2

[0036] The method is the same as in Example 1, and the laser energy is adjusted to 10mW;

[0037] The processing device is the same as in Example 1. After adjusting the optical path, adjust the angle of the molybdenum disulfide sample so that it forms an angle of 45° with the incident light, and the processing area is elliptical;

[0038] Processing process: control the movement of the translation stage, trigger the laser every 60 μm, and finally obtain a micro-nano composite structure on the surface of bulk molybdenum disulfide in a 2×3 array. Each elliptical area in the array can measure the same concentration or different concentrations. Processing results such as image 3 shown.

[0039] The processing lens of the patent of the present invention is not limited to use, and a surface Raman-enhanced substrate of any shape can be obtained on the surface of any bulk molybdenum disulfide material through different lenses, and can be prepared in a large area and at a high speed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com