A kind of high oil absorption rate polyvinyl chloride resin and preparation method thereof

A technology of polyvinyl chloride resin and high oil absorption, applied in chemical instruments and methods, and other chemical processes, can solve the problems of unfavorable environmental protection, difficult operation, etc., and achieve the effects of reduced migration, storage resistance, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

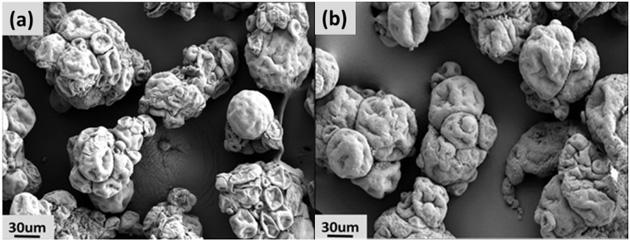

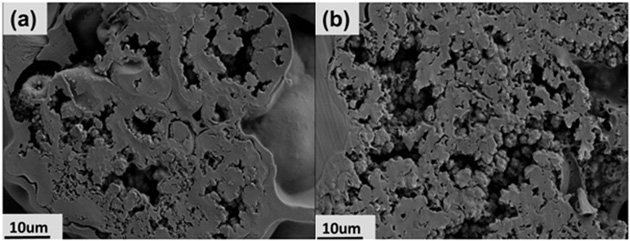

Embodiment 1

[0026] Deionized water 12Kg, organic dispersant high degree of alcoholysis polyvinyl alcohol dispersant BR-60 4.8g, hydrophilic cellulose ether dispersant BR-4 2.4g, low degree of alcoholysis polyvinyl alcohol dispersant TCR-4040 2.4 g, 2 g of hydrophobic nano-silica with trimethylsilane modified on the surface, 4 g of initiator cumyl peroxide neodecanoate, and 4 g of pH regulator sodium bicarbonate were added into the reaction kettle, and nitrogen gas was introduced to replace the air. Then add 8Kg of vinyl chloride monomer, pre-stir for 30min, and heat up to 57°C for reaction. When the pressure in the reactor dropped by 0.1 MPa, 0.4 g of terminator diethylhydroxylamine was added, the reaction was completed, unreacted vinyl chloride monomer was removed, and then filtered and dried to obtain polyvinyl chloride resin with high oil absorption rate.

Embodiment 2

[0028] Deionized water 12Kg, organic dispersant high alcoholysis degree polyvinyl alcohol dispersant BR-60 4.8g, hydrophilic cellulose ether dispersant BR-4 2.4g, surface-modified hydrophobic nanometer dioxide of trimethyl silicon 2g of silicon, 4g of initiator cumyl peroxide neodecanoate, and 4g of pH regulator sodium bicarbonate were added into the reaction kettle, and nitrogen gas was introduced to replace the air. Then add 8Kg of vinyl chloride monomer, pre-stir for 30min, and heat up to 57°C for reaction. When the pressure in the reactor drops by 0.1 MPa, add 0.4 g of diethylhydroxylamine as a terminator, the reaction is completed, remove unreacted vinyl chloride monomer, and then filter and dry to obtain polyvinyl chloride resin with high oil absorption rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

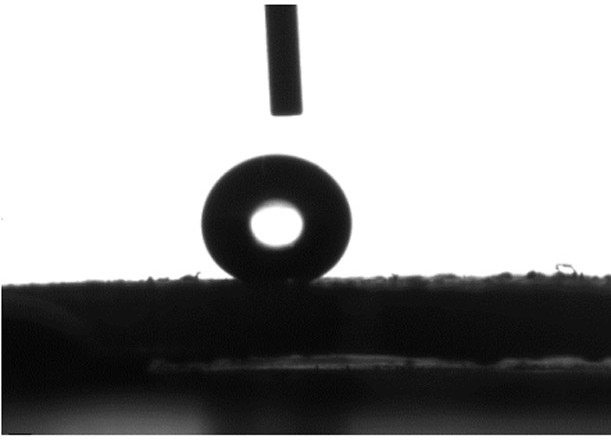

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com