Meal replacement powder containing cyclocarya paliurus leaves and coarse cereals and preparation method thereof

A technology of meal replacement powder and multigrain powder, applied in the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve the problems of not replacing diet, single function, etc. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

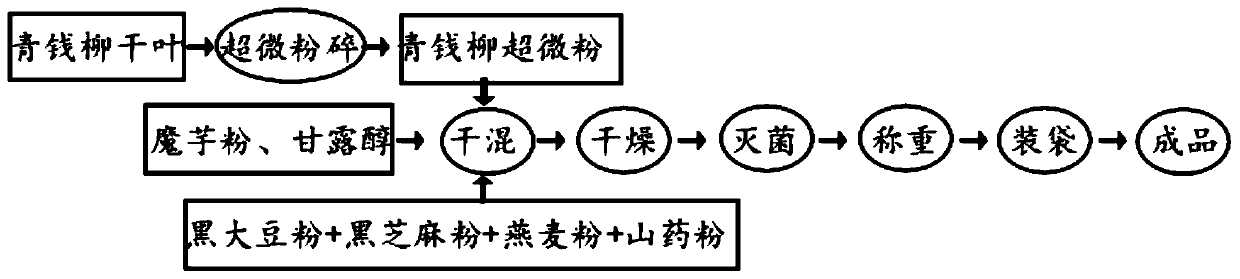

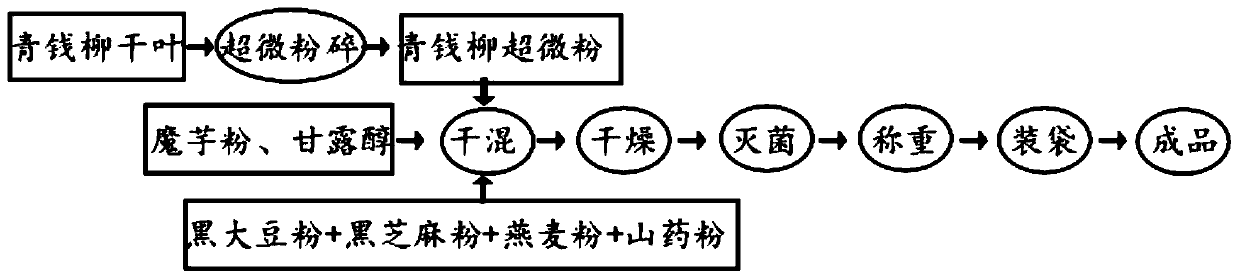

Method used

Image

Examples

Embodiment 1

[0032] Raw material composition: 2 parts of Cyclocarya paliurus, 5 parts of konjac flour, 20 parts of black soybean, 32 parts of oat, 15 parts of black sesame, 10 parts of Chinese yam, 40 parts of mannitol and 1 part of natural antioxidant.

[0033] Preparation:

[0034] S1. Preparation of Cyclocarya paliurus superfine powder: Wash and dry the old leaves of Cyclocarya paliurus, put them into a universal pulverizer and pulverize them, then put them into a ball mill for superfine pulverization, and then finely pulverize the Cyclocarya paliurus microparticles Sieve in a special sieving machine, put the particles on the sieve back into the ball mill for ultra-fine pulverization, and finally combine the fine powder under the sieve to obtain ultra-fine powder of Cyclocarya paliurus, the particle size of which is 10-12 μm ;

[0035] S2. Preparation of miscellaneous grain powder: drying black soybeans, oats, black sesame and yam at 68°C, pulverizing, passing through a 200-mesh sieve ...

Embodiment 2

[0038] Composition of raw materials: 8 parts of papaya papaya, 10 parts of konjac flour, 30 parts of black soybean, 40 parts of oat, 25 parts of black sesame, 20 parts of Chinese yam, 55 parts of mannitol and 2 parts of natural antioxidant.

[0039]Preparation:

[0040] S1. Preparation of Cyclocarya paliurus superfine powder: Wash and dry the old leaves of Cyclocarya paliurus, put them into a universal pulverizer and pulverize them, then put them into a ball mill for superfine pulverization, and then finely pulverize the Cyclocarya paliurus microparticles Sieve in a special sieving machine, put the particles on the sieve back into the ball mill for ultra-fine pulverization, and finally combine the fine powder under the sieve to obtain ultra-fine powder of Cyclocarya paliurus, the particle size of which is 10-12 μm ;

[0041] S2. Preparation of miscellaneous grain powder: drying black soybeans, oats, black sesame and yam at 62°C, pulverizing, passing through a 200-mesh sieve t...

Embodiment 3

[0044] Raw material composition: 3 parts of Cyclocarya paliurus, 6 parts of konjac flour, 22 parts of black soybean, 34 parts of oat, 19 parts of black sesame, 13 parts of Chinese yam, 46 parts of mannitol and 1.1 parts of natural antioxidant.

[0045] Preparation:

[0046] S1. Preparation of Cyclocarya paliurus superfine powder: Wash and dry the old leaves of Cyclocarya paliurus, put them into a universal pulverizer and pulverize them, then put them into a ball mill for superfine pulverization, and then finely pulverize the Cyclocarya paliurus microparticles Sieve in a special sieving machine, put the particles on the sieve back into the ball mill for ultra-fine pulverization, and finally combine the fine powder under the sieve to obtain ultra-fine powder of Cyclocarya paliurus, the particle size of which is 10-12 μm ;

[0047] S2. Preparation of miscellaneous grain powder: drying black soybeans, oats, black sesame and yam at 60°C, pulverizing, passing through a 200-mesh sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com