Semi-solid state magnesium alloy high-pressure injection molding machine

A magnesium alloy, semi-solid technology, applied in the field of forming and processing, can solve the problems of difficult quality assurance, slow forming speed, low processing efficiency, etc., and achieve the effect of excellent product quality, high dimensional accuracy and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

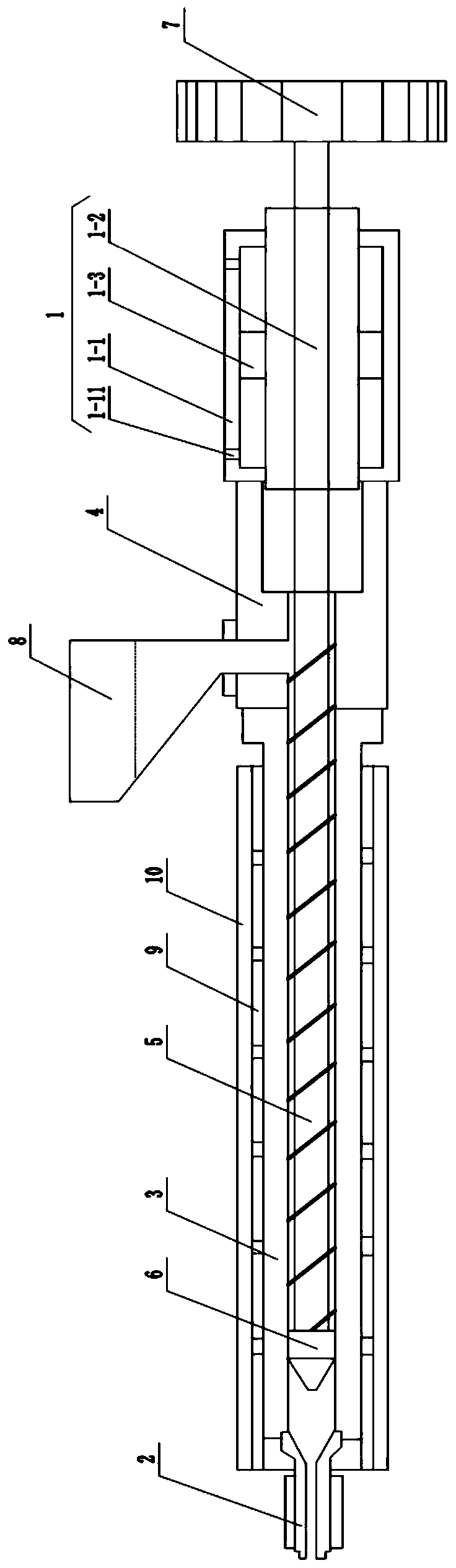

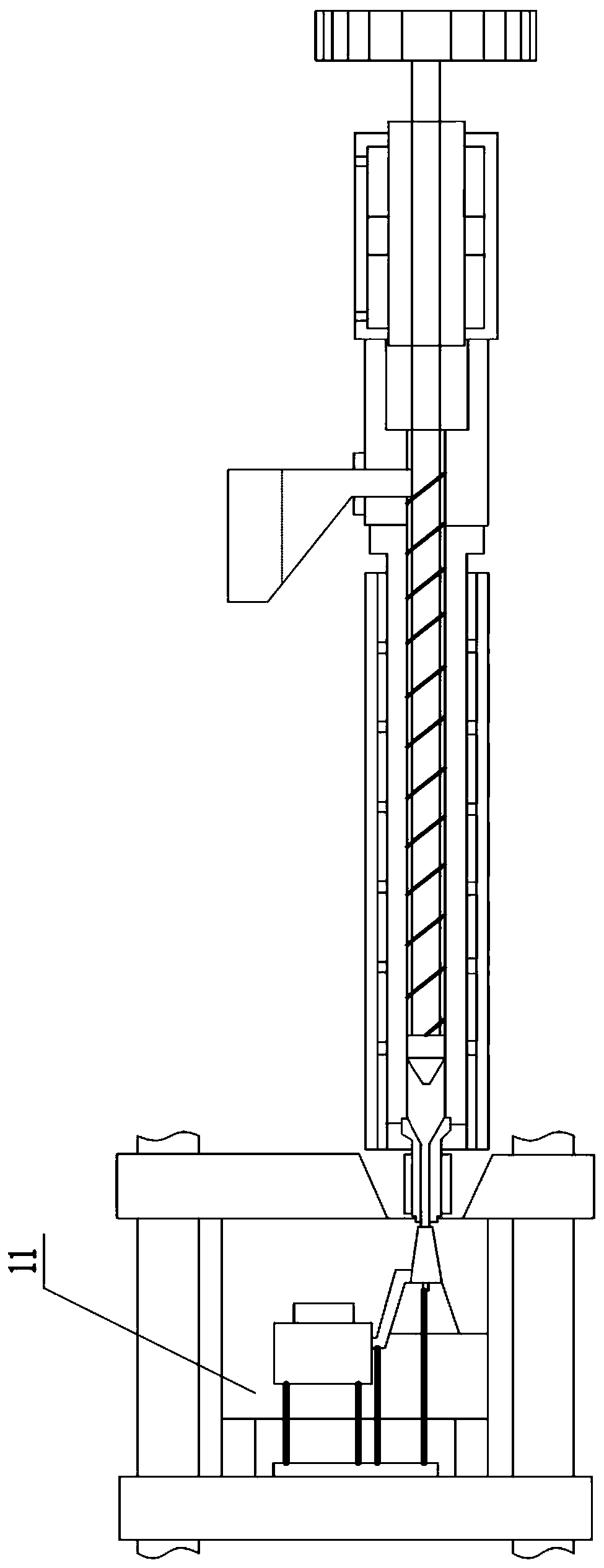

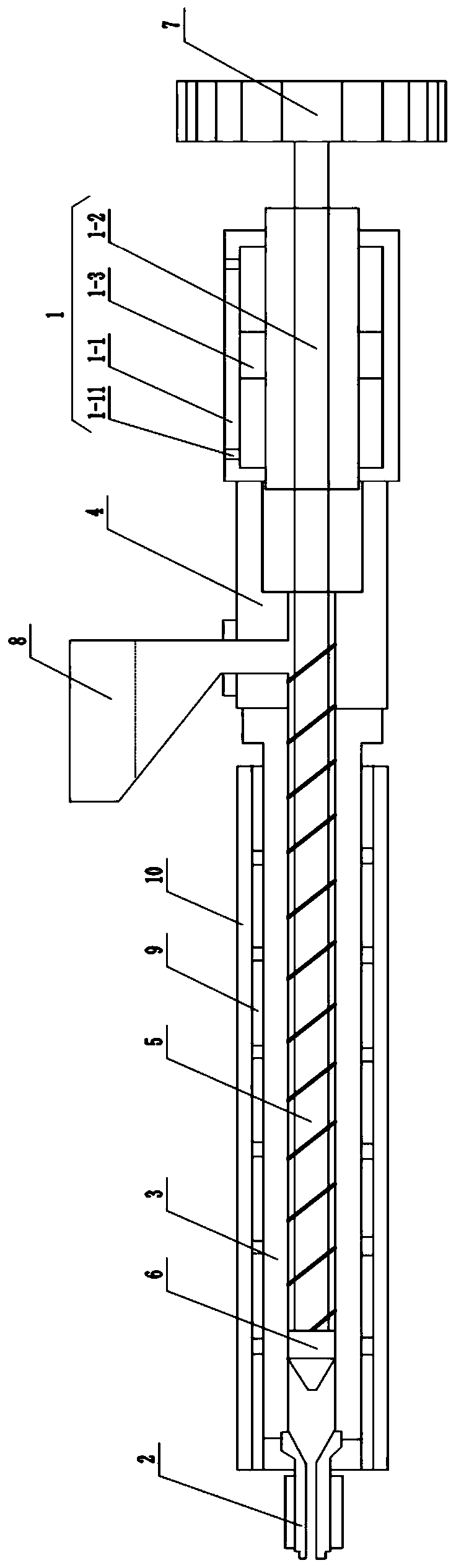

[0011] Such as figure 1 As shown, a semi-solid magnesium alloy high-pressure injection molding machine includes a hydraulic pushing device 1, a nozzle 2, a barrel 3, a connecting barrel 4, a screw 5, a non-return ring 6, a drive servo motor 7, a silo 8, a heating Device 9, cooling device 10.

[0012] The hydraulic pushing device 1 includes a box body 1-1, a pushing bearing 1-2 and a partition 1-3. The pushing bearing 1-2 is horizontally penetrated inside the box body 1-1, and the partition 1-3 is fixedly sleeved on the pushing bearing 1 -2 on the outer ring, and divide the inside of the tank 1-1 into two enclosed spaces. The tank 1-1 is provided with two oil delivery ports 1-11, and the openings are located in the cavities of the two enclosed spaces. Inside, the two oil delivery ports 1-11 can respectively deliver or extract hydraulic oil into the two enclosed spaces, and then push the partition 1-3 to make the pushing bearing 1-2 in the box 1-1 in the horizontal direction Move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com