Pressing mold for production of powder metallurgy parts and application of pressing mold

A technology of powder metallurgy and mold pressing, which is applied in the field of powder metallurgy, can solve the problems of reduced service life, reduced product hardness, and poor wear resistance of products, and achieve the effects of prolonging service life, uniform hardness, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for producing powder metallurgy parts, comprising the steps of:

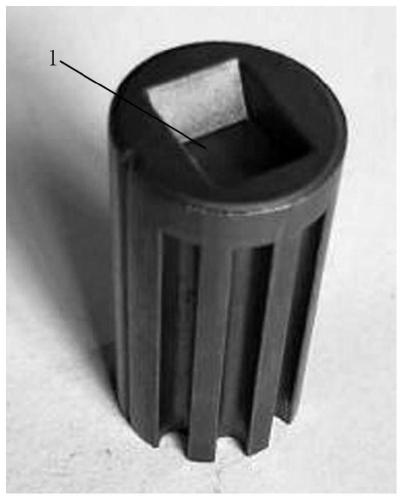

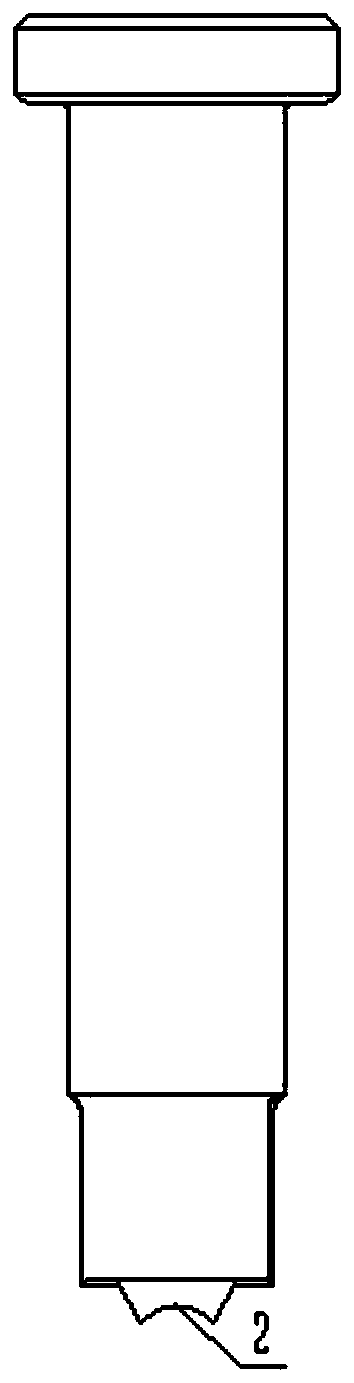

[0034] (1) The powder metallurgy raw material is pressed into shape by a pressing die; the pressing surface of the pressing die used to press the working surface of the part blank is a hemispherical concave surface, and the concave surface forms a hemispherical convex surface on the pressed blank, so The height of the highest position of the hemispherical convex surface accounts for 3% of the height of the molding body;

[0035] The powder metallurgy raw material is composed of the following components by weight percentage: graphite powder 0.6%, copper powder 3%, lubricant 0.6%, iron powder balance;

[0036] (2) Carry out sintering to the compacted green body, the sintering temperature is 1120 ℃ for 35 minutes, and the sintering process is protected by nitrogen gas;

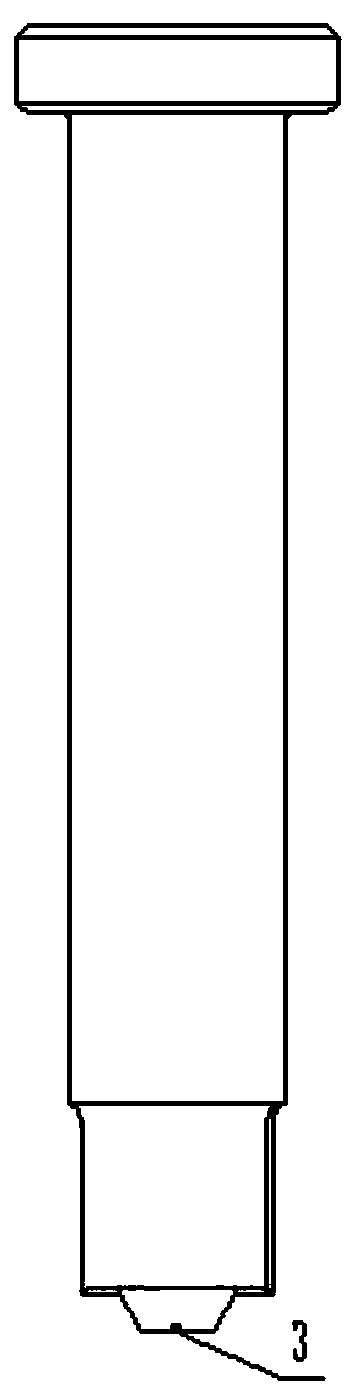

[0037] (3) The green body after sintering is put into a shaping mold for pressing and shaping; the shaping surface of the shaping...

Embodiment 2

[0041] A method for producing powder metallurgy parts, comprising the steps of:

[0042] (1) The powder metallurgy raw material is pressed into shape by a pressing die; the pressing surface of the pressing die used to press the working surface of the part blank is a hemispherical concave surface, and the concave surface forms a hemispherical convex surface on the pressed blank, so The height of the highest position of the hemispherical convex surface accounts for 4% of the height of the molding body;

[0043] The powder metallurgy raw material is composed of the following components by weight percentage: graphite powder 0.9%, copper powder 1%, lubricant 0.6%, iron powder balance;

[0044] (2) Carry out sintering to the compacted green body, the sintering temperature is 1120 ℃ for 40 minutes, and the sintering process is protected by nitrogen gas;

[0045] (3) the green body after sintering is put into the shaping mold for pressing and shaping; the shaping surface of the shapi...

Embodiment 3

[0049] A method for producing powder metallurgy parts, comprising the steps of:

[0050] (1) The powder metallurgy raw material is pressed into shape by a pressing die; the pressing surface of the pressing die used to press the working surface of the part blank is a hemispherical concave surface, and the concave surface forms a hemispherical convex surface on the pressed blank, so The height of the highest position of the hemispherical convex surface accounts for 3.5% of the height of the molding body;

[0051] The powder metallurgy raw material is composed of the following components by weight percentage: graphite powder 0.8%, copper powder 2%, lubricant 0.6%, iron powder balance;

[0052] (2) Carry out sintering to the compacted green body, the sintering temperature is 1120 ℃ for 40 minutes, and the sintering process is protected by nitrogen gas;

[0053] (3) The green body after sintering is put into a shaping mold for pressing and shaping; the shaping surface of the shaping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com