Hydrophobic cellulose nanosheet and preparation method thereof

A cellulose and hydrophobic technology, applied in the field of hydrophobic cellulose nanosheets and their preparation, achieves the effects of wide source of raw materials and simple operation of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of hydrophobic cellulose nanosheets, comprising the steps of:

[0029] 1) The wood pulp cellulose is crushed into a powder material, and vacuum-dried at 80° C. for 5 hours.

[0030] 2) Add 10ml of ferrous sulfate solution with a concentration of 0.25M into the zirconia ball mill jar.

[0031] 3) adding sulfuric acid to adjust the pH value to 6.

[0032] 4) Add 0.5 g of cellulose into a ball mill jar to obtain a prepreg, and crush the prepreg.

[0033] 5) Add 10ml of 0.25M hydrogen peroxide solution into the prepreg.

[0034] 6) Ball milling for 6 hours, the grinding balls are 7 zirconia balls with a diameter of 10 mm, and the grinding speed is 400 rpm.

[0035] 7) The product is centrifuged and washed with deionized water until neutral, and the centrifugation speed is 10000 rpm.

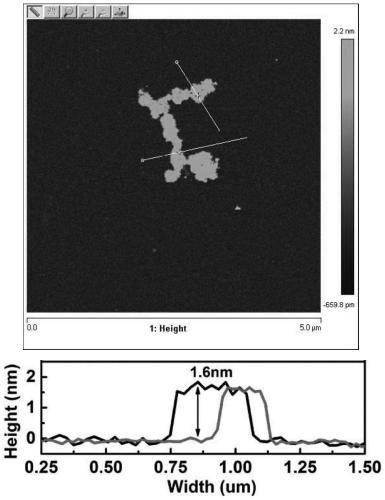

[0036] The obtained powder was mixed with ethanol to form a 0.04wt% suspension, ultrasonicated in a 100W water bath for 5min, and then 10ul of the dispersion was spin-...

Embodiment 2

[0038] A preparation method of hydrophobic cellulose nanosheets, the method is the same as in Example 1, except that:

[0039] Step 2) adding 10ml of ferrous sulfate solution with a concentration of 0.20M into the zirconia ball mill jar;

[0040] Step 3) adding sulfuric acid to adjust the pH value to 5.

Embodiment 3

[0042] A preparation method of hydrophobic cellulose nanosheets, the method is the same as in Example 1, except that:

[0043] Step 4) Add 0.6 g of linter cellulose into a ball mill jar to obtain a prepreg, and crush the prepreg.

[0044] Step 5) Add 10ml of 0.30M hydrogen peroxide solution into the prepreg.

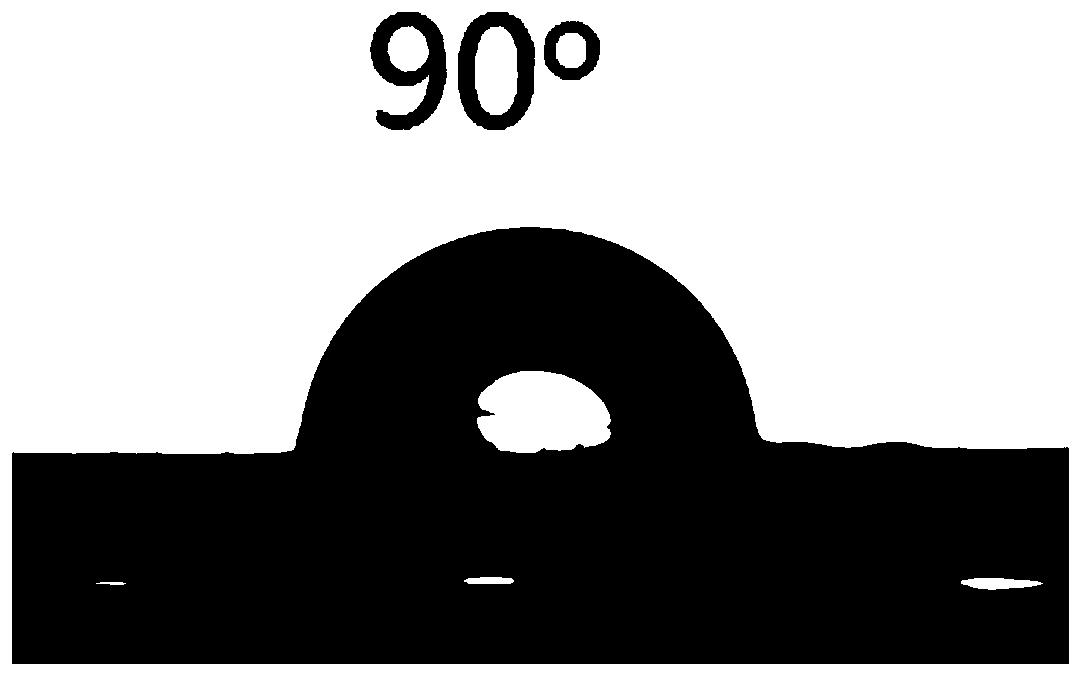

[0045] The obtained powder was pressed into tablets, and the contact angle was tested by static drop method, and the amount of water added was 2 μl. figure 2 It is the contact angle diagram of the cellulose nanosheet obtained in Example 3. It can be seen from the diagram that the obtained product exhibits a certain degree of hydrophobicity, and the contact angle is 90°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com