PTFE (polytetrafluoroethylene) composite, preparation method thereof and leakproof sealing ring using composite

A technology of polytetrafluoroethylene and composite materials, which is applied in the field of polytetrafluoroethylene composite materials, making the material, and non-leakage sealing rings, which can solve the problem that the sealing performance cannot meet the requirements of use, cannot meet the long-term use, and cannot guarantee the sealing effect, etc. problems, to achieve the effect of breaking through the shackles of formula design and production methods, making the production process clear, and solving the incompatibility of wear resistance and radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

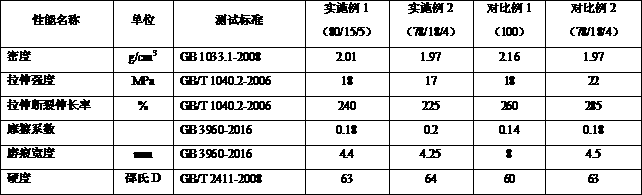

Embodiment 1

[0040] 1), surface treatment

[0041] Take a certain weight of thermosetting polyimide powder, put it in a blast drying oven at 300°C, and dry it for 1 hour. When the temperature drops to 22°C, store it for future use (airtight);

[0042] 2), mixing

[0043] In the mixing chamber of the mixing equipment, drop into 80 parts by weight of suspended polytetrafluoroethylene resin, 15 parts by weight of dried thermosetting polyimide powder and 5 parts by weight of copper calcium titanate powder, and mix uniformly to obtain the mixture. take out for use;

[0044] 3), suppression

[0045] Measure the mixture obtained in step 2) into the mold cavity of the automatic hydraulic press, open the equipment to press, the pressure per unit area is 50MPa, after pressing, demould and take out the material blank;

[0046] 4), sintering

[0047]Put the material blank obtained in step 3) into a PLC automatic control oven, and control the temperature change in the cavity according to the follow...

Embodiment 2

[0051] 1), surface treatment

[0052] Take a certain weight of thermosetting polyimide powder, put it in a blast drying oven at 300°C, and dry it for 1 to 2 hours. When the temperature drops to 23°C, store it for future use (airtight);

[0053] 2), mixing

[0054] In the mixing chamber of the mixing equipment, drop into 78 parts by weight of suspended polytetrafluoroethylene resin, 18 parts by weight of dried thermosetting polyimide powder and 4 parts by weight of copper calcium titanate powder, and mix uniformly to obtain the mixture. take out for use;

[0055] 3), suppression

[0056] Measure the mixture obtained in step 2) into the mold cavity of the automatic hydraulic press, open the equipment for pressing, the pressure per unit area is 55MPa, after pressing and forming, demould and take out the material blank;

[0057] 4), sintering

[0058] Put the material blank obtained in step 3) into the oven, and control the temperature change in the cavity according to the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com