A robot automatic cleaning system and method

A cleaning system and robot technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problem that silicon wafers cannot be automatically transferred and cleaned, and achieve the effect of ingenious structure, good verticality, and improved cleaning quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

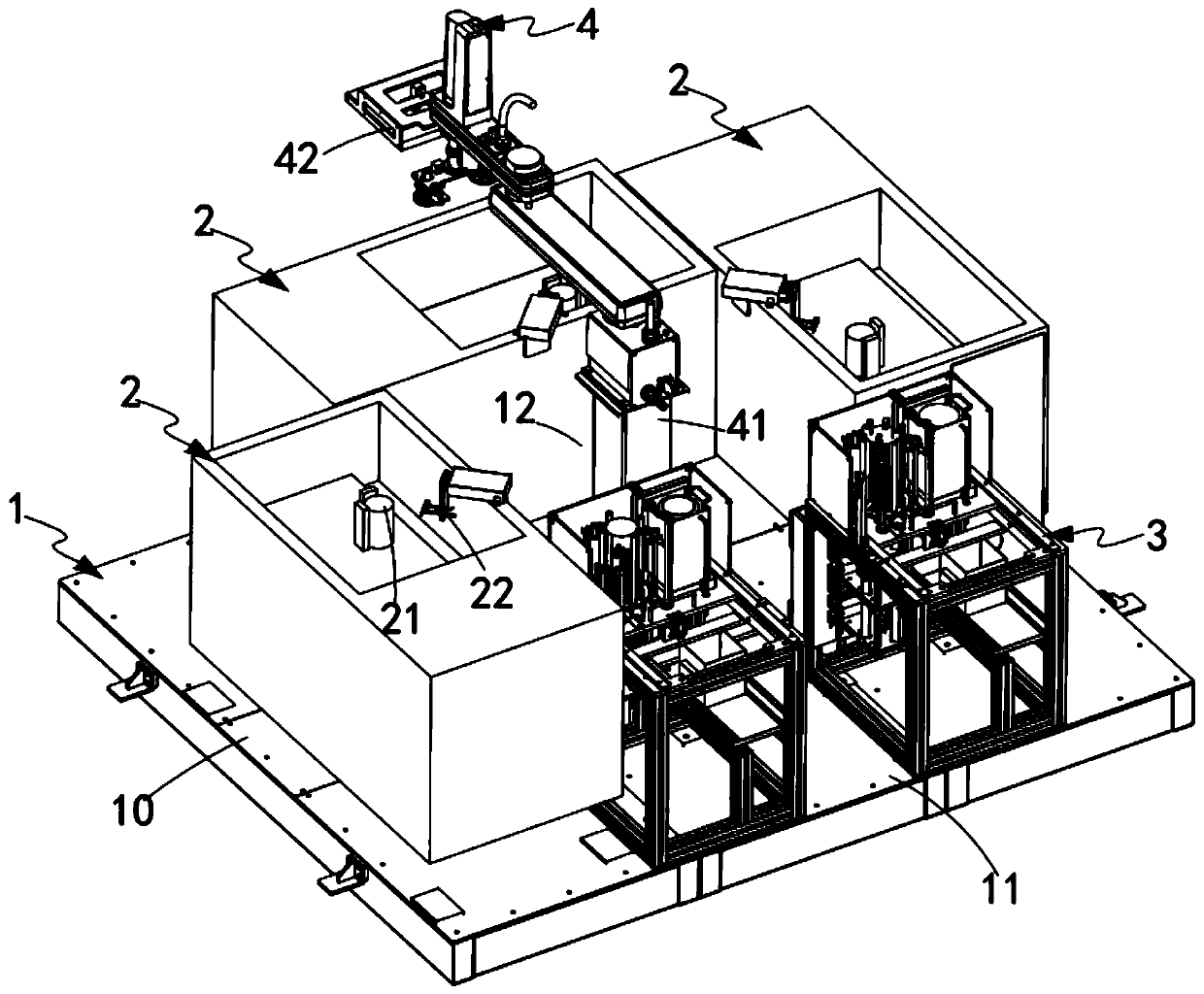

[0085] Such as Figure 1 to Figure 3 As shown, a robot automatic handling and cleaning system includes an installation platform 1, the installation platform 1 is a square setting, and any three sides of the installation platform 1 are cleaning stations 10, and the cleaning stations 10 are respectively equipped with The cleaning device 2 is characterized in that it also includes a loading and unloading station 11 arranged on the remaining side of the installation platform 1 and a transfer station 12 arranged in the middle of the installation platform 1;

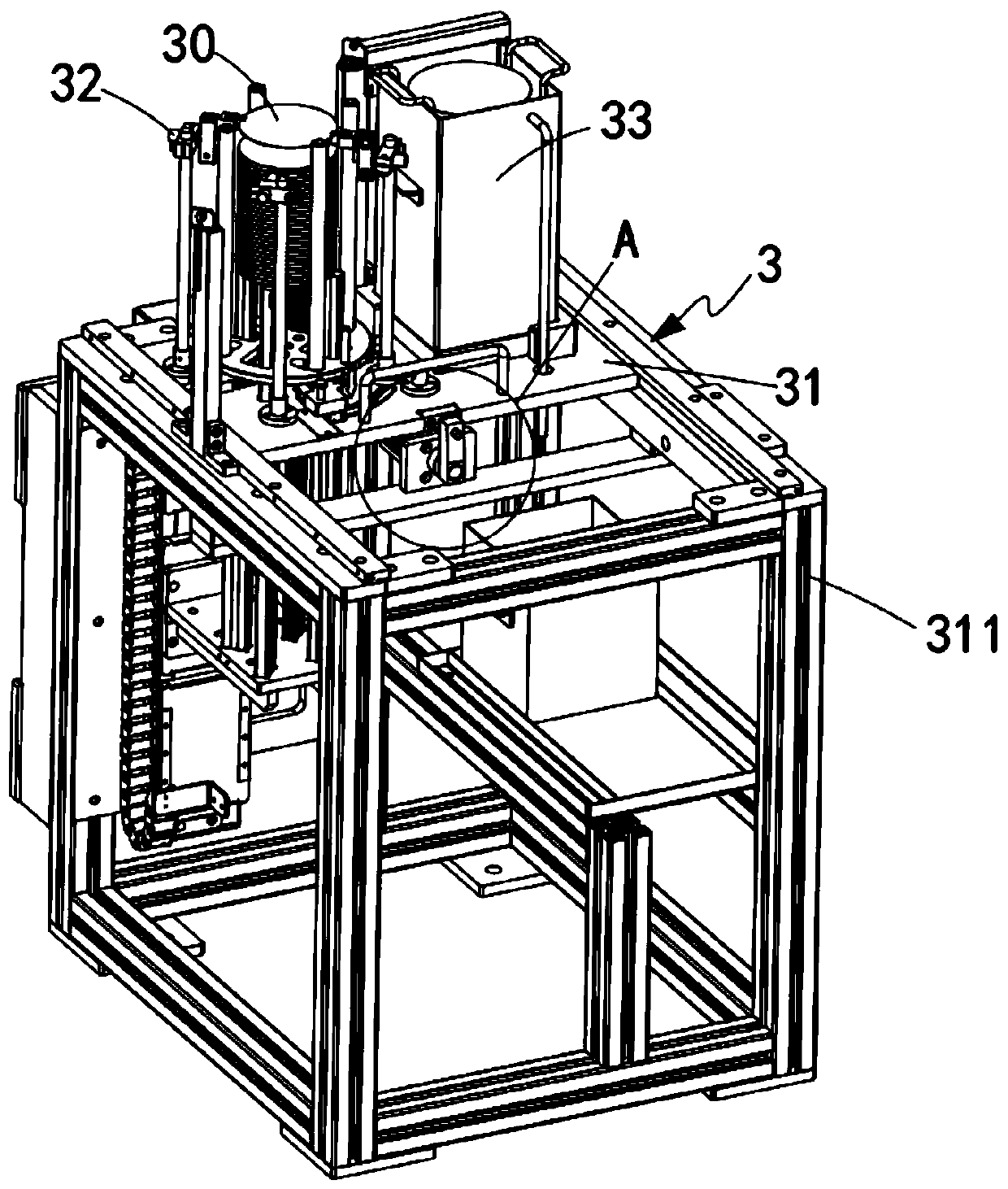

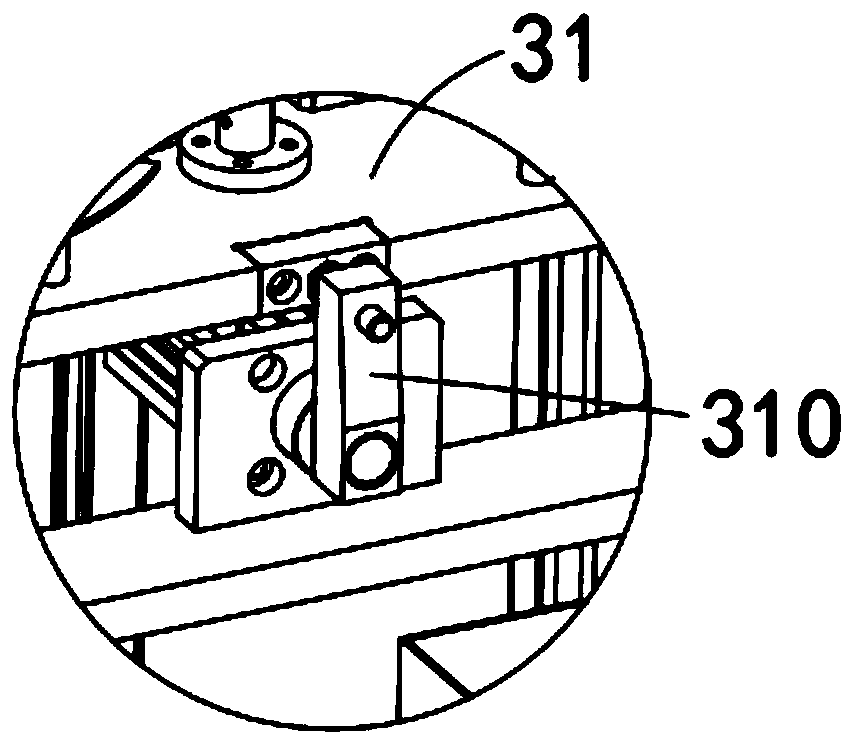

[0086] A loading and unloading device 3 is installed on the loading and unloading station 11, and the loading and unloading device 3 includes a movable workbench 31 and a feeding mechanism 32 and a buffer mechanism 33 installed on the workbench 31;

[0087] A transfer device 4 is installed on the transfer station 12, and the transfer device 4 includes a fixed installation column 41 and a rotatably grasping manipulator 42 insta...

Embodiment 2

[0141] Referring to the first embodiment, the specific working process of a method for automatically carrying and cleaning a robot according to the second embodiment of the present invention will be described.

[0142] Such as Figure 22 Shown, a kind of robot automatic handling cleaning method is characterized in that, comprises the following steps:

[0143] Step 1, discharging, the lifting assembly 321 drives the silicon wafer 30 placed on the support platform 322 to lift up to the brush 3241 located on the top of the stacking area 3230;

[0144] Step 2, separate, lift the silicon wafer 30 at the brush 3241 and the brush 3241 to reciprocate and rub in the vertical direction, so that the silicon wafer 30 at the top of the stacking area 3230 is separated from the adjacent silicon wafer 30 below to form a gap;

[0145] Step 3, air injection buffering, after the silicon wafer 30 at the top of the stacking area 3230 is separated from the adjacent silicon wafer 30 below to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com