Water-soluble zinc oxide dispersion slurry

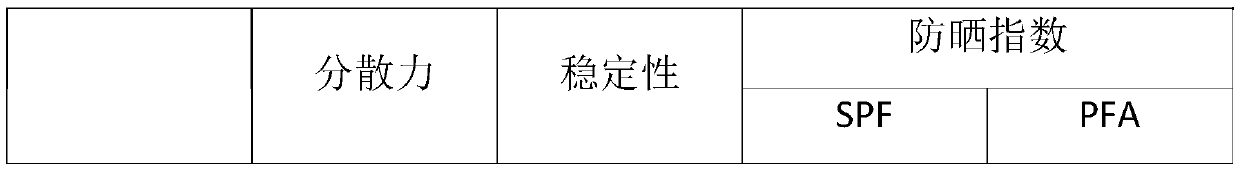

A zinc oxide, dispersing slurry technology, applied in cosmetics, cosmetic preparations, medical preparations containing active ingredients, etc., can solve the problems of increasing the difficulty of dispersion, heavy oil phase, etc., to achieve safety without dust pollution and strong covering power , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A water-soluble zinc oxide dispersion slurry, containing the following components in parts by weight: 35 parts of zinc oxide, 5 parts of glycerin, 1 part of caprylyl glycol, 5 parts of potassium cetyl phosphate, 0.5 part of phenoxyethanol, add water to The total mass of the dispersion slurry is 100 parts; the surface treatment agent of the zinc oxide is triethoxyoctylsilane; the particle size of the zinc oxide is 30 nanometers.

[0022] Mix the carrier (glycerin, water), dispersant potassium cetyl phosphate, and preservatives (caprylyl glycol, phenoxyethanol) completely by stirring, then put in zinc oxide powder, mix for 30 minutes and disperse until the dispersion reaches the standard Finally, filter and pack.

Embodiment 2

[0024] A water-soluble zinc oxide dispersion slurry, containing the following proportions: 60 parts of zinc oxide, 8 parts of butanediol, 11 parts of potassium cetyl phosphate, 2 parts of caprylyl glycol, 1 part of phenoxyethanol, add water to disperse The total mass of the slurry is 100 parts; the surface treatment agent of the zinc oxide is triethoxyoctylsilane; the particle size of the zinc oxide is 0.15 microns.

[0025] Mix the carrier (butanediol, water), dispersant potassium cetyl phosphate, and preservatives (caprylyl glycol, phenoxyethanol) completely by stirring, then put in zinc oxide powder, mix for 30 minutes and then disperse. After reaching the standard, filter and pack.

Embodiment 3

[0027] A water-soluble zinc oxide dispersion slurry, containing the following proportions: 50 parts of zinc oxide, 10 parts of butanediol, 10 parts of disodium sulfosuccinic acid monoylstearylamine, 2 parts of caprylyl glycol, 1, 2 hexyl 2 parts of diol, add water until the total mass of the dispersion slurry is 100 parts; the surface treatment agent of the zinc oxide is triethoxyoctylsilane; the particle size of the zinc oxide is 0.15 microns.

[0028] Mix the carrier (butanediol, water), dispersant disodium stearyl sulfosuccinate, and preservatives (caprylyl glycol, 1,2 hexanediol) by stirring completely, and then put in zinc oxide powder, After mixing for 30 minutes, disperse. After the dispersion reaches the standard, filter and pack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com