Medical needle with micronano compound antibacterial texture on surface and preparation method of medical needle

A micro-nano composite and nano-texture technology, applied in medical science, needles, applications, etc., can solve the problems of structural damage of the coating layer, uneven surface coating layer, etc., and achieve small heat-affected zone, complex processing shape, The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

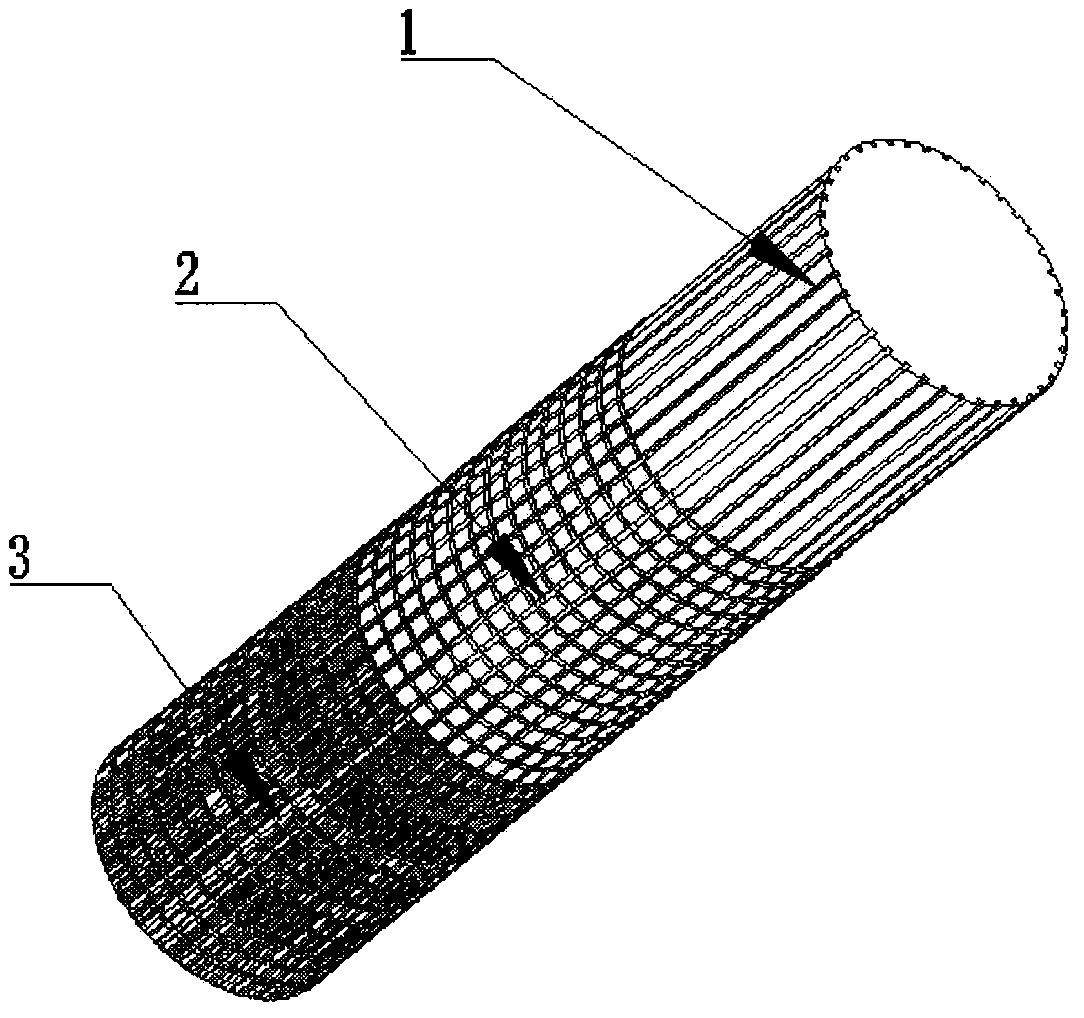

[0019] A medical needle with micro-nano composite texture on the surface, the specification is 16G (outer diameter 1.6mm), and the base material is 316L stainless steel. The specific preparation method is as follows:

[0020] (1) A stainless steel medical needle with a diameter of 1.6 mm is clamped on a precision rotary table, and an optical camera is used to focus and align the laser on the processed surface of the medical needle. The wavelength of the laser is 532nm, the pulse width is 10ps, and the spot diameter is 16μm.

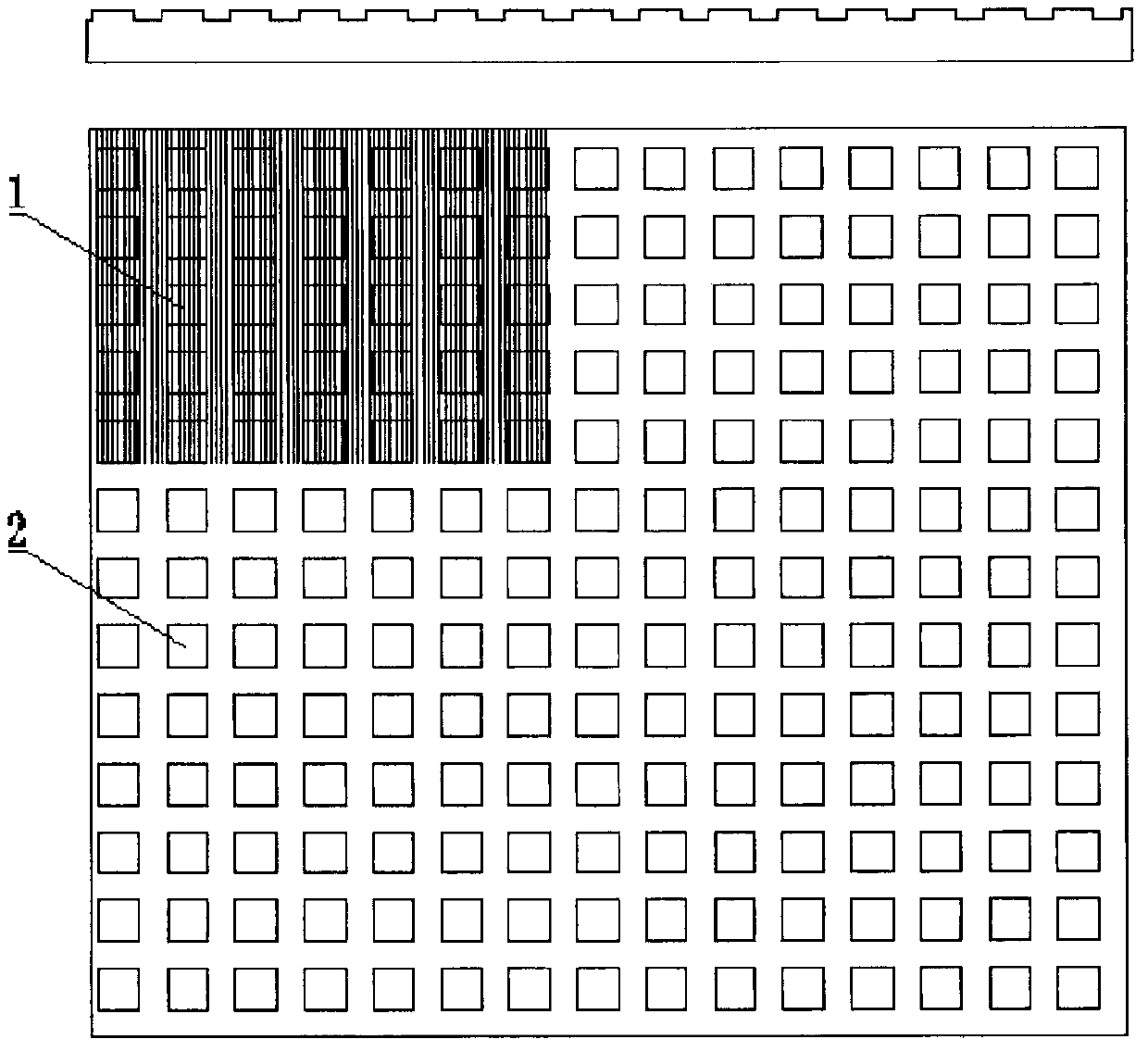

[0021] (2) A laser processing platform is used to process periodic nano-textures on the surface of stainless steel needles. The processing parameters are: laser frequency 50kHz, laser energy 0.35μJ, scanning speed 40mm / s, processing direction is axial, each medical needle is rotated 0.6°, repeated scanning times is 1 time, the processed nano-texture period 450nm.

[0022] (3) Use a laser platform to process the micron boss texture, the laser frequency ...

example 2

[0025] A medical needle with a micro-nano composite texture on the surface, the specification is 27G (outer diameter 0.4mm), and the base material is 304 stainless steel. The specific preparation method is as follows:

[0026] A medical needle with a micro-nano composite texture on the surface, the specification is 27G (outer diameter 0.4mm), and the base material is 316L stainless steel. The specific preparation method is as follows:

[0027] (1) A stainless steel medical needle with a diameter of 0.4mm is clamped on a precision rotary table, and an optical camera is used to focus and align the laser on the processed surface of the medical needle. The wavelength of the laser is 532nm, the pulse width is 10ps, and the spot diameter is 16μm.

[0028] (2) Use a laser processing platform to process periodic nanotextures. The processing parameters are: laser frequency 35kHz, laser energy 0.24μJ, scanning speed 20mm / s, processing direction is axial, each medical needle is rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com