A kind of reforming catalyst and preparation method thereof

A technology for reforming catalysts and compounds, which can be used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of charcoal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a kind of preparation method of reforming catalyst, and this preparation method comprises the following steps:

[0036] Step 1, preparing a tin-containing alumina carrier;

[0037] Step 2, impregnating the carrier of step 1, the impregnating solution includes platinum-containing compounds, light rare earth compounds, competing adsorbents and ammonium salts; and

[0038] Step 3, drying, activating and reducing the carrier impregnated in step 2 to obtain a reforming catalyst;

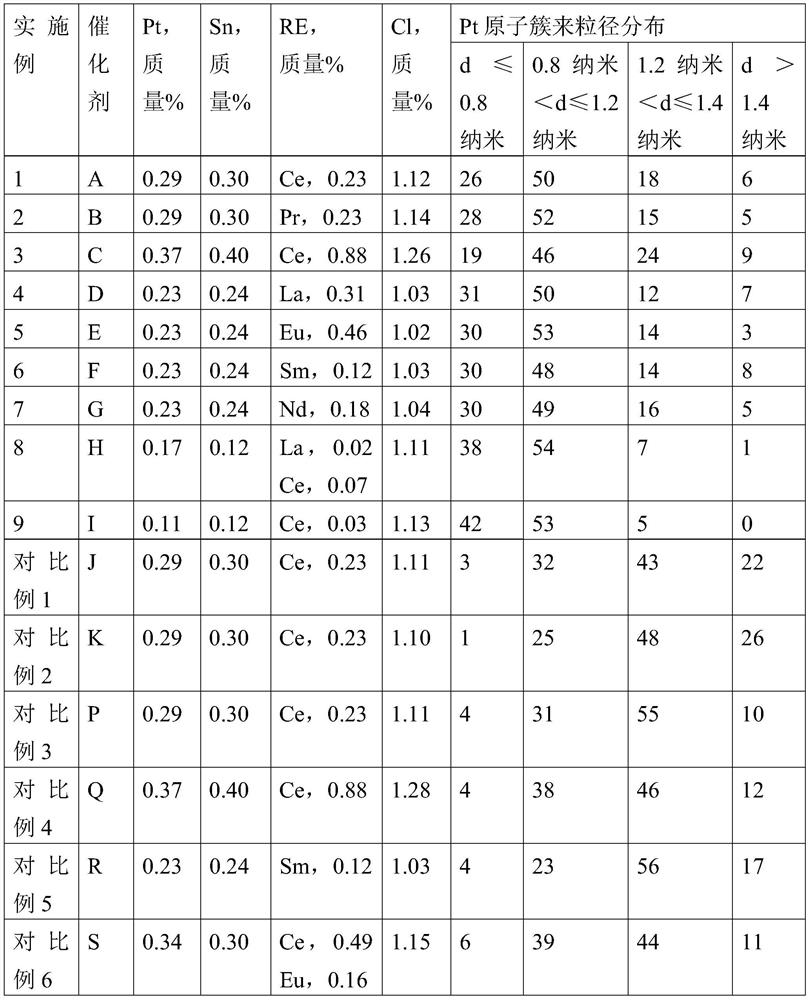

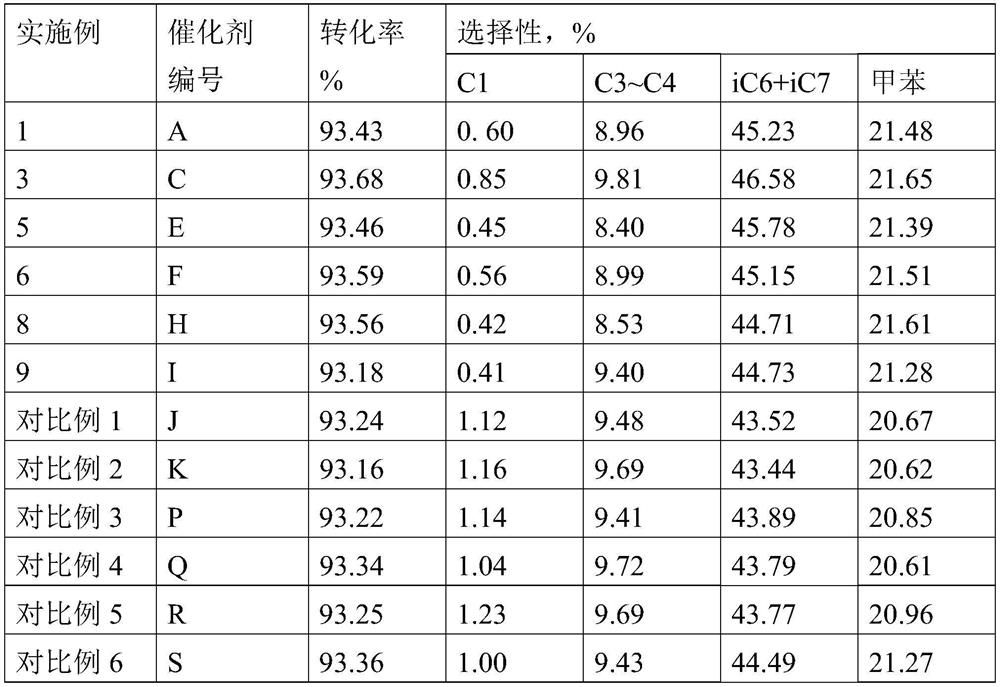

[0039] Wherein, based on the total mass of the alumina carrier on a dry basis, the reforming catalyst includes 0.1-0.4 mass % of platinum, 0.1-0.6 mass % of tin, 0.01-1 mass % of light rare earth and 0.3-3.0 mass % of chlorine .

[0040] In the present invention, the steps of preparing the tin-containing alumina carrier are not particularly limited, as long as the requirements of the present invention can be met. The shape of the alumina carrier can be strip-shaped...

Embodiment 1

[0057] Take 100 grams of pseudo-boehmite (manufactured by Sasol) and an appropriate amount of deionized water with a liquid / solid mass ratio of 2, and stir at room temperature for 0.5 hour slurrying. Then add 3 milliliters of nitric acid, and a predetermined amount of stannous chloride hydrochloric acid solution, so that the Sn content in the solution is 0.30% by mass relative to the alumina on a dry basis, and acidify for 2 hours. Then drop the ball into the oily ammonia column, solidify the wet ball in ammonia water for 1 hour, then filter, wash with deionized water three times, dry at 60°C for 6 hours, dry at 120°C for 2 hours, and bake at 650°C for 4 hours in a flowing air atmosphere. Hours, the Sn-containing alumina pellet carrier was obtained.

[0058] Prepare an impregnating solution containing chloroplatinic acid, cerous chloride, hydrochloric acid, and ammonium chloride according to a predetermined amount, and the content of platinum, cerium, HCl and ammonium salt in ...

Embodiment 2

[0060] Catalyst B is prepared according to the method of Example 1, except that the light rare earth compound is praseodymium chloride in the impregnation solution, and the specific steps are as follows:

[0061] Take 100 grams of pseudo-boehmite (manufactured by Sasol) and an appropriate amount of deionized water with a liquid / solid mass ratio of 2, and stir at room temperature for 0.5 hour slurrying. Then add 3 milliliters of nitric acid, and a predetermined amount of stannous chloride hydrochloric acid solution, so that the Sn content in the solution is 0.30% by mass relative to the alumina on a dry basis, and acidify for 2 hours. Then drop the ball into the oily ammonia column, solidify the wet ball in ammonia water for 1 hour, then filter, wash with deionized water three times, dry at 60°C for 6 hours, dry at 120°C for 2 hours, and bake at 650°C for 4 hours in a flowing air atmosphere. Hours, the Sn-containing alumina pellet carrier was obtained.

[0062]An impregnating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com